Catalog excerpts

Chromalox Thick Film Heater Technology Chromalox is all about precision heat and control.And no single product exemplifies this more than Chromalox > ή Thick Film Heaters. Chromalox > Thick Film Heaters provide the best possible combination of heat transfer,thermal efficiency, and temperature uniformity in applications where there is a need to save space in a product design. >

Open the catalog to page 1

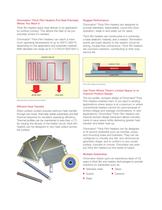

Chromalox > Thick Film Heaters Put Heat PreciselyWhere You Want It Rugged Performance Chromalox > ή Thick Film Heaters are designed to provide relentless, dependable, round-the-clock operation, week in and week out for years. Thick film heaters are constructed of a substrate,a base dielectric material, and a resistor. Termination points are fused directly to the resistor circuit for strong, trouble-free connections. Thick film heaters are corrosion-resistant, contributing to their long service life. Thick film heaters apply heat directly to an applicationby surface contact. This allows the...

Open the catalog to page 2

Chromalox > Thick Film Heaters Are Ideal for aVariety of Applications Chromalox > ή Will Assist you Every Step of the Way Experienced Chromalox engineers are available toassist you in the selection of the right Chromalox Chromalox > Thick Film Heaters offer efficient heatingfor appliances, localized and concentrated heating for medical devices, and thermal uniformity with rapid heating and cooling for semiconductor fabrica- tion. Some of the many other applications that can benefit by Chromalox > ή Thick Film Heater for your application.The Chromalox research and development staff canassist...

Open the catalog to page 3

Substrate Materials > ■ Carbon Steel > ■ PET > ■ Stainless Steel (304, 316, 430) > ■ Aluminum > ■ Ceramic (mullite, alumina, aluminum nitride,steatite, Macor > ■ Mylar > glass ceramic) > ֠ Beryllium Oxide > ■ Quartz > ■ Silicon Nitrate > ■ Pyrex > ■ Glass > ■ PVC Paste Materials > ■ Conductive inks, resistive inks, dielectric inks > ■ Cermet (for high-temperature applications) > ■ Polymer (for low-temperature applications) > ■ Exotic materials available upon request, or as determined by application Patterning > ■ Minimum of 3 mil line deposition > ■ Minimum of 1 mil line spacing Sheet...

Open the catalog to page 4All Chromalox catalogs and technical brochures

-

Tubular V-Seal

2 Pages