Website:

Chr. Mayr GmbH + Co. KG

Website:

Chr. Mayr GmbH + Co. KG

Catalog excerpts

your reliable partner

Open the catalog to page 1

your reliable partner Safety brake systems for gravity-loaded axes ROBA-stop® brakes by mayr® prevent inadvertent dropping or crashing of vertical axes. ❒ Reliable safety protecting people in all operating modes ❒ Controlled operational safety due to an integrated function monitoring system ❒ Minimal braking distances due to short reaction times and high brake performance density ❒ Optimum adaptation for individual axes construction due to different brake concepts ❒ Economic and problem-free to retrofit pre-existing axes Additional measures are required to minimise the potential risk of a...

Open the catalog to page 2

your reliable partner Modular safety brake system for a A-bearing-side servomotor attachment Highlights and Advantages ❒ DGUV (German Social Accident Insurance) test certificate: B raking device as "tried and tested component" in terms of the Category 1 acc. DIN EN ISO 13849-1 Tested Safety ❒ The leading system on the market for vertical axes with rotatory drives ❒ The axis is held safely in any position, even with a dismantled servomotor, e.g. during machine maintenance ❒ Safe braking on EMERGENCY STOP and power failure ❒ Long lifetime even after frequent EMERGENCY STOP brakings ❒ Highest...

Open the catalog to page 3

your reliable partner ROBA®-topstop® – Designs ROBA®-topstop® with shaft design Type 899.000.0_ This brake type can be integrated into existing drives without any additional constructive work, or can be retrofitted. The output-side brake flange connection dimensions and the shaft dimensions equal the servomotor connection dimensions. A screw plug allows access to the clamping screw on the motor-side clamping hub construction. Radial forces can be absorbed by the ball bearing brake shaft, so that mounting belt pulleys and therefore operation in belt pulley drive systems is easily possible....

Open the catalog to page 4

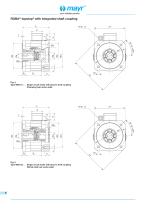

your reliable partner ROBA®-topstop® – Designs ROBA®-topstop® with plug-in coupling for mounting directly onto ball screw spindles Types 899.011._ _ and 899.012._ _ Type 899.01_._ _ Single circuit brake with standard output flange The brake Types 899.01_._ _ are specially conceived for direct installation onto ball screw spindles. A backlash-free, plug-in ROBA®-ES Type series shaft coupling is integrated into the brake housing to compensate for axial, radial and angular shaft misalignment. This makes separate coupling housing and shaft couplings unnecessary. The coupling hub to be mounted...

Open the catalog to page 5

your reliable partner ROBA®-topstop® single circuit brake Technical Data Dimensions 100 120 Correlation of bore diameters d1, dependent on respective transmittable torques (without key) Preferred Bore Sizes Frictionally-locking transmittable torques (Clamping hub motor-side) Tr [Nm] Suitable for F7 / k6 Table 1 The transmittable torques for the clamping connection allow for the max. tolerance backlash on a solid shaft: Tolerance k6 / bore (d1): tolerance F7. If the tolerance backlash is larger, the torque decreases. 1) Braking torque tolerance: -20 % / +40 %, 2) Coil capacity on...

Open the catalog to page 6

o mayr your reliable partner _ ROBA®-topstop® with output shaft and shaft coupling Single circuit brake with bearing-supported output shaft and Single circuit brake with bearing-supported output shaft and with plug-in shaft coupling (clamping hub motor-side) with plug-in shaft coupling (shrink disk hub motor-side) Optional key design possible. Optional key design possible. 1) Braking torque tolerance: -20 % / +40 %, 2) Coil capacity on overexcitation 3) Coil capacity at holding voltage 4) Braking torque increased only with overexcitation (see operational instructions) 5) For further...

Open the catalog to page 7

your reliable partner ROBA®-topstop® with integrated shaft coupling L2 Fig. 4 Type 899.011._ _ Single circuit brake with plug-in shaft coupling (Clamping hub motor-side) Fig. 5 Type 899.012._ _ Single circuit brake with plug-in shaft coupling (Shrink disk hub motor-sid

Open the catalog to page 8

Technical Data 1) Braking torque tolerance -20 % / +40 % 2) Coil capacity on overexcitation 3) Coil capacity at holding voltage 4) Braking torque increased only with overexcitation (see operational instructions) 5) For further information on flexible coupling e.g. angle misalignments, spring stiffness or temperature resistance please see ROBA®-ES catalogue K.940.V__._ _ 6) The transmittable torques in bores d2, d3 und d4 are dependent on the diameter, see tables 2 and 3. 7) On sizes 175: Tolerance field h7 *) - Sizes 175 and 200: Over a shaft length of 60 mm, only possible with a bored...

Open the catalog to page 9

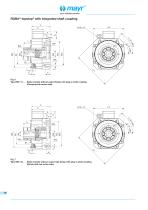

your reliable partner ROBA®-topstop® with integrated shaft coupling L3 Fig. 6 Type 899.111._ _ Brake module without output flange with plug-in shaft coupling (Clamping hub motor-side) Fig. 7 Type 899.112._ _ Brake module without output-side flange with plug-in shaft coupling (Shrink disk hub motor-side)

Open the catalog to page 10

transmittable torques (without key) Frictionally-locking transmittable torques Shrink disk hub Frictionally-locking transmittable torques Clamping hub Suitable for F7 Braking torque tolerance: -20 % / +40 %, Coil capacity on overexcitation Coil capacity at holding voltage Braking torque increased only with overexcitation (see operational instructions) For further information on flexible coupling e.g. angle misalignments, spring stiffness or temperature resistance please see ROBA®-ES catalogue K.940.V__._ _ The transmittable torques in bores d2, d3 und d4 are dependent on the diameter, see...

Open the catalog to page 11

your reliable partner ROBA®-topstop® – Examples: Further options as special designs ROBA®-topstop® single circuit brake with a bearing-supported output shaft, a hand release lever and protection IP65 A hand release lever is available for the ROBA®-topstop® single circuit brake standard design as a special accessory. Please note that the hand release prevents the safety brake from functioning during operation. With hand release lever, only Protection IP54 possible. Size 200 (Type 899.___._2) hand release not possible. Another option is the extended Protection IP65: => Protection motor-side:...

Open the catalog to page 12All Chr. Mayr GmbH + Co. KG catalogs and technical brochures

-

Test stand technology

16 Pages

-

Steel industry

12 Pages

-

Wind energy

24 Pages

-

Stage Technology – Applications

20 Pages

-

Elevator Brakes

24 Pages

-

Machine Tool Components

20 Pages

-

Robotics and Automation

20 Pages

-

EAS®-Sp/Sm/Zr

24 Pages

-

EAS®-smartic®

12 Pages

-

EAS®-reverse

4 Pages

-

EAS®-HTL

8 Pages

-

EAS®-HT

28 Pages

-

EAS®-HSE

16 Pages

-

ROBA®-capping head

12 Pages

-

EAS®-dutytorque

8 Pages

-

ROBA®-contitorque

12 Pages

-

ROBATIC®

60 Pages

-

EAS®-axial

24 Pages

-

ROBA®-drive-checker

4 Pages

-

ROBA®-DS (heavy duty)

80 Pages

-

ROBA®-ES

32 Pages

-

smartflex®

8 Pages

-

ROBA®-DS for torque transducers

16 Pages

-

ROBA®-DS (steel)

80 Pages

-

ROBA®-DS (servo)

80 Pages

-

ROBA®-slip hub

24 Pages

-

EAS®-compact® F

32 Pages

-

EAS®-compact®

40 Pages

-

ROBA®-takt

60 Pages

-

ROBA®-SBCplus

4 Pages

-

tendo®-PM

44 Pages

-

ROBA®-secustop

8 Pages

-

ROBA®-twinstop®

12 Pages

-

ROBA®-duplostop®

12 Pages

-

ROBA®-alphastop®

8 Pages

-

ROBA-stop®-stage

4 Pages

-

ROBA-stop®-S

12 Pages

-

ROBA®-quick

60 Pages

-

ROBA®-linearstop H

16 Pages

-

ROBA®-linearstop E

16 Pages

-

ROBA®-guidestop

32 Pages

-

ROBA®-diskstop®

8 Pages

-

ROBA-stop®-M Eco

4 Pages

-

ROBA-stop-M servo pitch

8 Pages

-

ROBA®-linearstop P

16 Pages

-

ROBA-stop®-silenzio®

28 Pages

-

ROBA-stop®-M

24 Pages

-

ROBA®-servostop® Lean

12 Pages

-

ROBA®-servostop® Cobot

12 Pages

-

ROBA®-servostop® Classic

12 Pages