Website:

Chr. Mayr GmbH + Co. KG

Website:

Chr. Mayr GmbH + Co. KG

Catalog excerpts

your reliable partner ROBA®-servostop® The perfect safety brakes for servomotors and lightweight robots Reliable function due to fail-safe principle The spring applied ROBA®-servostop® is closed in de-energised condition. It provides the required braking torque even in the event of an emergency stop, a power failure or when the power supply is interrupted. To ensure that the ROBA®-servostop® brakes also provide sufficient friction work in emergency stop situations and brake movements with a defined braking torque, a friction lining developed for this purpose with a corresponding steel...

Open the catalog to page 2

your reliable partner ROBA®-servostop® – Overview of the series ROBA®-servostop® Classic • High braking torque Classic series for installation into A- or B-bearing shield of servomotors • Wear-resistant - large number of emergency stops (dynamic brakings) are allowed • Easy installation Performance data Nominal braking torque: 1.5 up to 100 Nm Max. speed: 3000 up to 9500 rpm Page 4 ROBA®-servostop® Lean • Slim design Slim series for installation into A- or B-bearing shield of servomotors • Easy installation • High performance density at low energy consumption peration with overexcitation...

Open the catalog to page 3

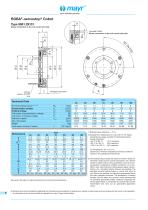

ROBA®-servostop® Classic Type 8980.00100 Screw connection on the coil carrier front side Technical Data to 60 °C: For higher temperatures, please consider the following braking torque reductions: >60 °C to 80 °C: 10 % reduction >100 °C to 120 °C: 30% reduction For temperature -20 °C to 0 °C: Observe the “Ambient temperature/Climate conditions” section in the operational instructions! The braking torque values are based on friction values determined in tests at mayr® power transmission. As a friction system is influenced by many parameters, such as mounting situation, temperature, ambient...

Open the catalog to page 4

your reliable partner ROBA®-servostop® Classic – InstallationExamples Screw connection on the coil carrier front side Screw connection on the coil carrier back side The brakes are screwed on via threaded holes in the coil carrier and through holes, e.g., in the bearing flange (provided by the customer). The braking torque is transmitted into the hub via the toothing of the rotors. The hub must be fixed axially. Observe the installation dimensions! The braking torque is transmitted from the hub to the shaft via a key (provided by the customer). The brakes are screwed on via threaded holes in...

Open the catalog to page 5

Technical Data We reserve the right to make dimensional and constructional alterations. 1) Braking torque tolerance: + 75 % 2) Suitable for a temperature of 0 up to 60 °C: For higher temperatures, please consider the following braking torque reductions: >60 °C to 80 °C: 10 % reduction For temperature -20 °C to 0 °C: Observe the “Ambient temperature/Climate conditions” section in the operational instructions! 3) The braking torque values are based on friction values determined in tests at mayr® power transmission. As a friction system is influenced by many parameters, such as mounting...

Open the catalog to page 6

your reliable partner ROBA®-servostop® Lean – InstallationExamples Screw connection on the coil carrier front side Screw connection on the coil carrier back side The brakes are screwed on via threaded holes in the coil carrier and through holes, e.g., in the bearing flange (provided by the customer). The braking torque is transmitted into the hub via the toothing of the rotors. The hub must be fixed axially. Observe the installation dimensions! The braking torque is transmitted from the hub to the shaft via a key (provided by the customer). The brakes are screwed on via threaded holes in...

Open the catalog to page 7

your reliable partner We reserve the right to make dimensional and constructional alterations. 1) Braking torque tolerance: + 75 % 2) Suitable for a temperature of 0 up to 60 °C: For higher temperatures, please consider the following braking torque reductions: >60 °C to 80 °C: 10 % reduction For temperature -20 °C to 0 °C: Observe the “Ambient temperature/Climate conditions” section in the operational instructions! 3) The braking torque values are based on friction values determined in tests at mayr® power transmission. As a friction system is influenced by many parameters, such as mounting...

Open the catalog to page 8

o mayr your reliable partner _ The brakes are screwed on via threaded holes in the coil carrier with through holes, e.g., in the bearing flange (provided by the customer). The rotor disk with the friction lining pads is screwed to the collar of the stepped shaft or hollow shaft (provided by the customers). Observe the installation dimensions! The brake is mounted via through holes, e.g., in the bearing shield (provided by the customer) and threaded holes in the coil carrier rear side. The rotor disk with the friction lining pads is screwed to the collar of the stepped shaft or hollow shaft...

Open the catalog to page 9

Keys MBr = Braking torque Ml = Load torque Connection time Response delay on connection UH = Holding voltage UN = Coil nominal voltage U0 = Overexcitation voltage

Open the catalog to page 11

**mayr your reliable partner Headquarters Chr. Mayr GmbH + Co. KG EichenstraBe 1, D-87665 Mauerstetten Tel.: +49 83 41/8 04-0, Fax: +49 83 41/80 44 21 www.mayr.com, E-Mail: public.mayr@mayr.com Service Germany/Austria Branch office China Mayr Zhangjiagang Power Transmission Co., Ltd. Fuxin Road No.1298, Yangshe Town 215637 Zhangjiagang Tel.: 05 12/58 91-75 67 Fax: 05 12/58 91-75 66 info@mayr-ptc.cn France Mayr France S.A.S. Z.A.L. du Minopole Rue Nungesser et Coli 62160 Bully-Les-Mines Tel.: 03.21.72.91.91 Fax: 03.21.29.71.77 contact@mayr.fr Great Britain Mayr Transmissions Ltd. Valley...

Open the catalog to page 12All Chr. Mayr GmbH + Co. KG catalogs and technical brochures

-

Test stand technology

16 Pages

-

Steel industry

12 Pages

-

Wind energy

24 Pages

-

Stage Technology – Applications

20 Pages

-

Elevator Brakes

24 Pages

-

Machine Tool Components

20 Pages

-

Robotics and Automation

20 Pages

-

EAS®-Sp/Sm/Zr

24 Pages

-

EAS®-smartic®

12 Pages

-

EAS®-reverse

4 Pages

-

EAS®-HTL

8 Pages

-

EAS®-HT

28 Pages

-

EAS®-HSE

16 Pages

-

ROBA®-capping head

12 Pages

-

EAS®-dutytorque

8 Pages

-

ROBA®-contitorque

12 Pages

-

ROBATIC®

60 Pages

-

EAS®-axial

24 Pages

-

ROBA®-drive-checker

4 Pages

-

ROBA®-DS (heavy duty)

80 Pages

-

ROBA®-ES

32 Pages

-

smartflex®

8 Pages

-

ROBA®-DS for torque transducers

16 Pages

-

ROBA®-DS (steel)

80 Pages

-

ROBA®-DS (servo)

80 Pages

-

ROBA®-slip hub

24 Pages

-

EAS®-compact® F

32 Pages

-

EAS®-compact®

40 Pages

-

ROBA®-takt

60 Pages

-

ROBA®-SBCplus

4 Pages

-

tendo®-PM

44 Pages

-

ROBA®-secustop

8 Pages

-

ROBA®-twinstop®

12 Pages

-

ROBA®-duplostop®

12 Pages

-

ROBA®-alphastop®

8 Pages

-

ROBA®-topstop®

24 Pages

-

ROBA-stop®-stage

4 Pages

-

ROBA-stop®-S

12 Pages

-

ROBA®-quick

60 Pages

-

ROBA®-linearstop H

16 Pages

-

ROBA®-linearstop E

16 Pages

-

ROBA®-guidestop

32 Pages

-

ROBA®-diskstop®

8 Pages

-

ROBA-stop®-M Eco

4 Pages

-

ROBA-stop-M servo pitch

8 Pages

-

ROBA®-linearstop P

16 Pages

-

ROBA-stop®-silenzio®

28 Pages

-

ROBA-stop®-M

24 Pages

-

ROBA®-servostop® Cobot

12 Pages

-

ROBA®-servostop® Classic

12 Pages