Website:

Chotest Technology Inc.

Website:

Chotest Technology Inc.

Catalog excerpts

Universal Thread Measuring Machine

Open the catalog to page 1

In 2 min, measure all parameters of plug or ring gauge

Open the catalog to page 2

Functions 1. Thread measurement function 1) Full-automatic measurement for comprehensive parameters of cylindrical thread plug gauges, cylindrical thread ring gauges, taper thread plug gauges, taper thread ring gauges, plain ring gauges, plain plug gauges and other gauges with internal & external dimensions, including virtual pitch diameter , single pitch diameter, basic pitch diameter, major diameter, minor diameter, thread pitch, thread angle, half of thread angle, flank straightness, lead angle, taper, etc. 2) Can measure trapezoidal thread, buttress thread, sawtooth thread and other...

Open the catalog to page 3

2. One sided or two-sided profile measurement 1) Scan measurement: T-shaped Measuring probe contacts and measures surface of test object. The machine measures and inspects profile, two-dimensional dimension, two-dimensional displacement of the test object. Particularly, it can direct measure holes, grooves and other special part which can not be measured by traditional measuring instruments, moreover, it can qualify the data according to corresponding standard, or describe surface contour curve. The measurement is fast with reliable test result. 2) Graphical analysis: Based on profile shape...

Open the catalog to page 4

2. High accuracy, high stability and high repeatability ---1----------+ ^ l--------------- 1) Leading high-speed multi-channel, high-precision linear encoder system: The resolution of linear encoder is up to 0.01um and its repealabiJ^ isJess=than=0.1um. . 2) Accurate^ control system of measuring force: Stable and reliable contact measurement is achieved by accurate control system of measuring force, in addition, error resulted from unstable measuring force is reduced. Its measuring force is much less than the one of similar machine from other company. The small measuring force helps to...

Open the catalog to page 5

4. 3D navigation function 3D navigation graphics of Measuring probe, workholder and workpiece is built by applying 3D graphics technology, which realizes real-time & multi-angle display, consequently, probability of collision of Measuring probe is minimized. The operating convenience, accuracy, safety and reliability are improved greatly. 5. Convenient and accurate replacement of Measuring probe In the innovative structure for installation of Measuring probe, the pin holder is fixed vertically(the pin holder aligns cross section of thread). This structure eliminates errors caused by...

Open the catalog to page 6

6. Combined workholder --1----------J—ii— Decrease the frequently-used workholders from 4 to 2 by applying Two-in-one and three-in-one ones without gasket and heel block. All these workholders can be used for measuring both thread ring gauges and thread plug gauges. By reducing frequency of installation&uninstallation&calibration of different workholders, the operation is more simple and the work is more efficient, in addition risk of operating errors is down mudh. Some special gauges and workpieces can be measured and analyzed by profile measurement and analysis function. Moreover, the...

Open the catalog to page 7

Outside meas.range Inside meas.range Dimension Measuring uncertainty: Cylindrical or Taper thread ring gauge(Minor diameter>2.5mm,half of thread angle≥27°) Minor diameter Actual pitch diameter Thread pitch Cylindrical or Taper thread plug gauge(Major diameter>1mm,half of thread angle≥27°) Major diameter Actual pitch diameter Thread pitch Plain ring / plug gauge Other measurement Outside meas.range Inside meas.range Measuring uncertainty: Cylindrical or Taper thread ring gauge(Minor diameter>2.5mm,half of thread angle≥27°) Minor diameter Actual pitch diameter Thread pitch Cylindrical or...

Open the catalog to page 9

0 CHOTEST Thread gauge measurement

Open the catalog to page 10

Standard configuration Standard configuration 3. Measuring probes group 3. Measuring probes group 4. Software module for trapezoidal thread measurement 5. Standard plain ring gauges 5. Measuring probes for trapezoidal thread measurement 6. Standard plain plug gauges 6. Software module for profile measurement 7. Built-in regulations and standards 8. Standard plain ring gauges 9. Standard plain plug gauges 10. HP color laser printer 10. Built-in regulations and standards 11. Aluminum alloy suitcase for accessories 13. Product certification and warranty card 13. HP color laser printer 14....

Open the catalog to page 11

0Technology innovation ^1. SmartTouch intelligent scanning technology By using real-time control device and intelligent sensing device for measuring force, the problem of abrasion of measuring pin is solved, particularly large-slope thread can be direct measured. The measuring force is adjustable from 0.1~10gf by realtime control device which can adjust measuring force accurately. Resolution of intelligent sensing device is up to 0.1gf, which can help to | protect measuring pin very well. I I No abrasion to measuring probe Real-time control unit of measuring force SmartTouch technology...

Open the catalog to page 12

2. Precision air-bearing guide rail system The guide rail works stably and reliably by using precision air-bearing guide rail system with micro friction and no abrasion. Air-bearing guide rail Travel direction Travel direction Work principle of Air-bearing guide rail system Features of precision air-bearing guide rail system: - Travel linear accuracy 1um - Repeated positioning accuracy - Perpendicularity error of X axis and Z axis

Open the catalog to page 13

3. Ingenious balancing mechanism technology When air-bearing slider bears the extra force in one direction, the whole guide rail system will deflect because the air film of sliding sleeve inclines in one direction and adjustment ability is insufficient, as shown in figure below, Travel direction Sensor 2 Balancing mechanism principle

Open the catalog to page 14

The problem of Z-axis swing while X-axis movement is solved by using ingenious balancing mechanism. Swing of Z axis guide rail is less than 0.5μm while X axis moves under entire measuring length in scanning, but it is 6μm for the similar machine from other company. Balancing mechanism principle There is a balancing unit G1 in air-bearing guide rail system. When air-bearing sleeve G2 of X axis travels, G1 and G2 move to opposite direction, particularly the weight of G1 and G2 is the exact same, consequently, Air-bearing guide rail system is always balanceable.

Open the catalog to page 15All Chotest Technology Inc. catalogs and technical brochures

-

PRODUCT CATALOGUE

67 Pages

-

WR50 Rotary Axis Clibrator

4 Pages

-

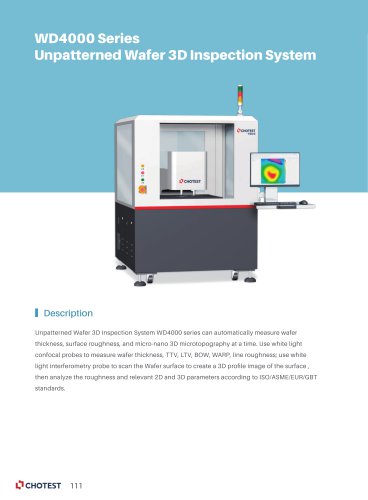

WD4000 SERIES

4 Pages

-

PO40 PO40L PO60

2 Pages

-

SJ5800-100 SJ5800-200

4 Pages

-

SJ5900-100 SJ5900-200

4 Pages

-

VX1060 VX1100

1 Pages

-

Laser Interferometer SJ6000

4 Pages

-

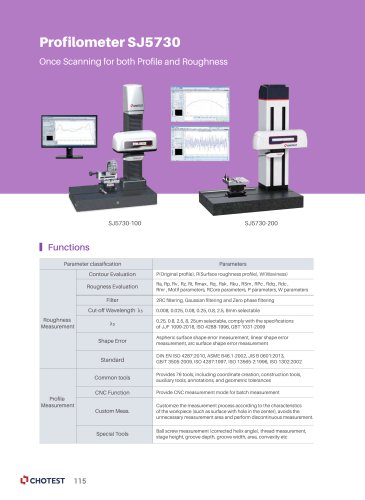

Profilometers SJ57 Series

8 Pages

-

Profilometer SJ5700 Series

4 Pages