Website:

Chotest Technology Inc.

Website:

Chotest Technology Inc.

Catalog excerpts

Bidirectional constant measuring force Absolute Measurement over entire measuring range 0 CHOTEST Description Thanks to precision glass-scale, precision guide rail and precision temperature compensation unit, cooperating with different probes and workholders, SJ5100 achieves high-precision measurement of various dimensional gauges. Moreover, because straightness of precision guide rail is every small, its repeatability is excellent by applying by bidirectional constant measuring force technology. After the software records the coordinates from precision glass-scale and introduces the feedback data of measuring force device and temperature sensor, the dimensional parameters are calculated according to the relevant definitions and formulas from selected norm. The whole measurement process can be completed in 3minutes. 1. Measure gauge blocks, thread gauges, plain gauges, Taper thread/plain gauges, pin gauge, caliper, spline gauges, setting bars, snap gauges, internal/external micrometers, feeler gauges, Dial indicators, dial bore gauge, dial test gauges, internal micrometer three points, etc. 2. Measure various gauges according to GB, ISO, BS, ANSI, DIN, JIS, API standards. With comprehensive and professional standards in database, it meets requirements of most customers. 3. Conform to a variety of verification regulations & measuring standards. All test results are generated according to relevant regulations and standards. 5.With centralized database management for measuring records, the operator can query and manage the measuring records according to object type , testing institution, manufacturing number, inspector, submitted institution, equipment number, inspection date and effective date. 6. Can print multiple selected test records or test certificates from database at once time. 7. Can export test data to Word, Excel, AutoCAD (optional) files. 8. Data backup and restore. 9.Support user-defined template of report. 10. Support user-defined program and tolerance.

Open the catalog to page 1

Typical Application Plain ring gauge Bearing outer ring Taper thread ring gauge Software Interface Inside micrometer Thread plug gauge Bearing inner ring Gauge blcok Outside micrometer Thread ring gauge Taper plain ring gauge

Open the catalog to page 2

More Application Dial indicator Snap gauge Inside micrometer three points 3m outside micrometer Item No. Abso l ute Outside range Inside range Indication error Repeatability (2s) Resolution Max pitch diameter(mm) Measuring force Dimension(mm) Weight (kg) Item No. Five-axis object table Z-axis Y-axis X-axis floation Z-axis rotation Y-axis yaw Loading capacity Dimension Indication error series*• • (0.15+L/1000)pm; B series*• • (0.25+L/1000)pm (Note* L is • measured^ length in mm) (Note* L is^ measured^ length in mm) Repeatability (2s) Resolution Max pitch diameter(mm) Measuring force...

Open the catalog to page 3

OCHOTEST Configuration 1* Absolute measurement: Thanks to precision glass-scale for positioning of measuring spindle, SJ5100 can implement the precision absolute measurement over the entire range. 2* High precision and High stability: (1) Precision glass-scale; Resolution: 0.01 |jm. (2) Precision grinding guide rail with excellent straightness lays foundation for accuracy and stability of measurements. (3) Measuring values are acquired truly and accurately by using high-rigid and deformation-free measuring slider. (4) Thanks to marble base, the machine is protected against external...

Open the catalog to page 4All Chotest Technology Inc. catalogs and technical brochures

-

PRODUCT CATALOGUE

67 Pages

-

WR50 Rotary Axis Clibrator

4 Pages

-

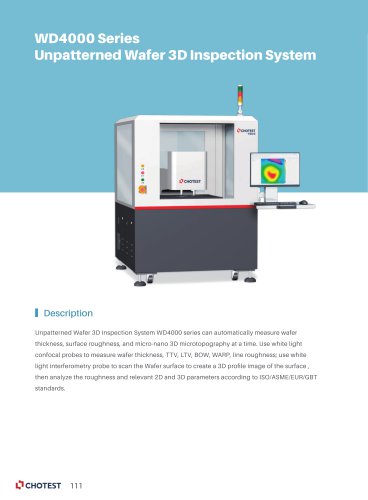

WD4000 SERIES

4 Pages

-

PO40 PO40L PO60

2 Pages

-

SJ5800-100 SJ5800-200

4 Pages

-

SJ5900-100 SJ5900-200

4 Pages

-

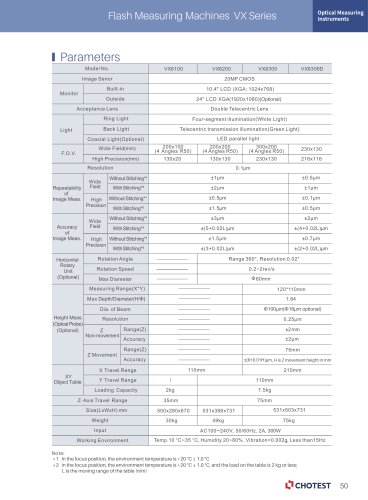

VX1060 VX1100

1 Pages

-

Laser Interferometer SJ6000

4 Pages

-

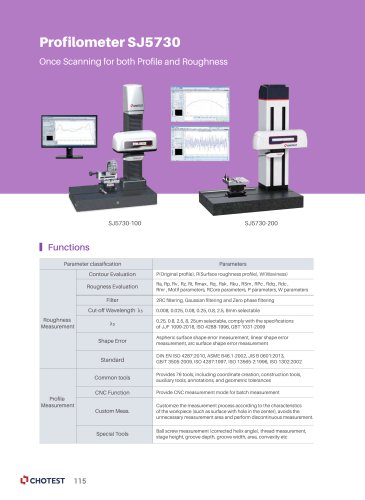

Profilometers SJ57 Series

8 Pages

-

Profilometer SJ5700 Series

4 Pages