Website:

Chotest Technology Inc.

Website:

Chotest Technology Inc.

Catalog excerpts

OCHOTEST From nanometer to hectometer we provide professional precision measurement solutions I? CHOTESTChotest Technology Inc. Office Add: 2/F, Building B1, Zhiyuan, Xueyuan Road, Xili, Nanshan, Shenzhen, China Factory Add: 1/F, Building No.7, HKC Industry Park, Shiyan, Baoan, Shenzhen, China Tel: 0755-83318988-227 Fax:0755-83312849 E-mail: sales@chotest.com One-Touch Measurement Please visit our website for more information NOTE:CHOTEST HAS MADE CONSIDERABLE EFFORTS TO ENSURE THE CONTENT OF THIS DOCUMENT IS CORRECT ATTHE DATE OF PUBLICATION BUT MAKES NO WARRANTIES OR REPRESENTATIONS REGARDING THE CONTENT. lssued:Feb., 2025

Open the catalog to page 1

0 CHOTEST Since established in 2002, Chotest Technology Inc. is focusing on the designing and manufacturing of precision dimensional measurement and calibration instruments. With more than about twenty years of professional technology accumulation, Chotest has accumulated rich practical experience and set up a strong team who is specialized in optics, machinery. Electronics and information technology. At present, CHOTEST has more than 100 technology patents and software intellectual property rights. With competence in Micro-Nano motion, 3D Reconstruction of Micro-Nano measurement, 3D Form...

Open the catalog to page 2

Efficient measurement One-Touchmeasurement Touch Measure button

Open the catalog to page 4

Light Source Clear image even if there are stages Equipped with a high depth optical lens and automatic focusing, the flash measuring machine only needs to focus at the tested object once. Even if there are variations in height, the images remain clear. Back light Zero distortion in the full field of view 75° Ring light OCHOTEST 8 OCHOTEST 9

Open the catalog to page 5

Rotary chuck Height probe It is a white light confocal probe, and can be used to measure thickness, height difference, flatness, parallelism, etc. Moreover, this probe can scan the surface of the sample continuously. Rotary chuck can rotate 360°. It is convenient to measure the sizes in different section according to rotation angle specified by the operator. It is an ideal solution to measure all kinds of cylindrical parts, such as shaft, etc.

Open the catalog to page 6

DXF Import Vision X professional visual measurement software is completely independently developed by CHOTEST, and CHOTEST has independent intellectual property rights. VisionX has friendly user interface, convenient operation, powerful and practical functions, support more than 80 kinds of extraction and analysis tools, including feature extraction tool, auxiliary tool, annotation tool and special application tool, etc. Moreover, functions can be customized according to user's need, so as to improve work efficiency more effectively. Measurement data can be obtained from CAD drawings. Even...

Open the catalog to page 7

The QR code on the sample can be defined as inspection information. Profile Tolerance ■ This tool has three evaluation methods: No reference (only shape error evaluation). Single reference. Multiple references. ■ Multiple annotations: Multiple profile tolerance can be annotated in a single program.-No need to establish a coordinate system: Just need to enter the reference in the drawing .Measurement of profile tolerance in different coordinate systems can be achieved in a single program. It can measure both point position tolerance and line position tolerance. Evaluation can be performed by...

Open the catalog to page 8

Fixed Position Measurement Automatic Multi-Object Matching The system supports automatic measurement of multiple objects, up to 1024 objects at a time. 360-degree rotation search function, tested objects can be easily recognized and automatically measured, regardless of their orientation. The measurement sequence of the samples can be customized. Z-order numbering N-order numbering When there are many circles located together on a sample, extracting circles one by one can be time-consuming and labor-intensive. This tool allows the diameter of the circles to be quickly extracted and...

Open the catalog to page 9

Barcode Scanner Conjoint program Combine Wide F.O.V. and High Precision F.O.V.: Wide F.O.V. mode allows efficient measurement for large dimensions. High precision F.O.V. mode focuses on small dimensions of the test object, ensuring accuracy. The barcode value which is read by Scanner can be saved as inspection information, or used to search program according to definition of the operator. Software can combine two programs with different measurement views of the test object as a Conjoint one. During CNC measurement, two sub-programs can be performed sequentially on different views, then all...

Open the catalog to page 10

Statistical Analysis The statistical analysis interface has the tabs of [Statistical Value], [Trend Chart], [Histogram] and [Data List] Measurement results and its main statistical information (e.g. average value, a, 3a, 6a, Ca, Cp, Cpk etc) will be automatically recorded and saved. Operator could search records by different conditions. By quality diagnosis and analysis, SPC statistical method can not only realize the monitoring of product quality, but also reflect the change trend in the generation process, reduce the waste caused by post-inspection, so as to achieve the effect of...

Open the catalog to page 11

Evaluate the measured values against the given design value and upper/lower tolerances specified on the drawing. Divide the tolerance into multiple grades according to tolerance percentage. Evaluate the sample's grade based on the actual measured value, so it can be used for pre-warning of processing equipment's state. Feature name Measured value Assessment result Design value Point positton-XPCI] Point posltloB-Y[Y1| Positional airgnme.. Gon«nirioy( >S«i| D19.(021 Feature name Pomt posttiorvXJXH Polni posuon-YTYl] Positional alignm Carcenlndyf1| Di3.[®2] veiilcai[Yii Measured vatue...

Open the catalog to page 12

Test reports can be generated simple and fast, such as PDF, WORD, EXCEL CSV and TXT. Automatically calculate Cp and Cpk. Real-time trend chart or histogram display quality trends and changes during measurements. ■ Custom Excel Report Measurement data & corresponding test images and inspection info are automatically exported into a designated Excel template in real time. Measurement data is transmitted to the MES system of the customer via socket or FITTP protocols in realtime. VisionX also could receive commands from the external server to load the program and begin measurement, so it is...

Open the catalog to page 13All Chotest Technology Inc. catalogs and technical brochures

-

PRODUCT CATALOGUE

67 Pages

-

WR50 Rotary Axis Clibrator

4 Pages

-

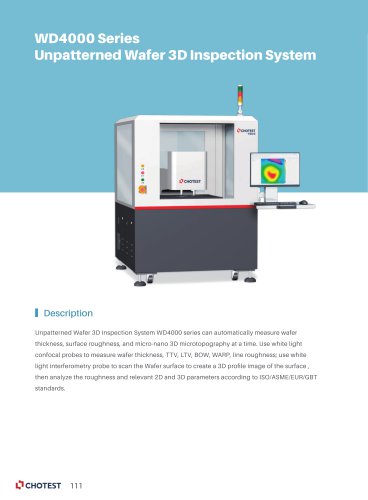

WD4000 SERIES

4 Pages

-

PO40 PO40L PO60

2 Pages

-

SJ5800-100 SJ5800-200

4 Pages

-

SJ5900-100 SJ5900-200

4 Pages

-

VX1060 VX1100

1 Pages

-

Laser Interferometer SJ6000

4 Pages

-

Profilometers SJ57 Series

8 Pages

-

Profilometer SJ5700 Series

4 Pages