Website:

Chotest Technology Inc.

Website:

Chotest Technology Inc.

3D Optical Surface Profilometer SuperView W1 SuperView W1-Pro SuperView W1-Ultra SuperView W1-Lite

1 /

4Pages

Catalog excerpts

3D Optical Surface Profilometer SuperView W1 3D Optical Surface Prof ilometer White Light Interferometry It is used for measurement and analysis of surface roughness and profile of precision components from industries of semi-conductor, 3C Electronics, ultraprecise machining, optical machining, Nano 3D Surface Form and Roughness micro-nano materials, micro-electro-mechanical system. Super smooth lens Unique re-establishment algorithm can filter noises of surface of test object. Cut sheet, coated sheet, wafer IC Roughness, microcosmic Sapphire screen, glass screen, Ink screen Roughness, flatness, step height Precision mould, optical lens Roughness, flatness,profile, radius of curvature Film roughness, film thickness Surface profile , Surface roughness, area, volume Abraded surface Vacuum Object Table Interference Lens Different magnification lenses are selectable for various test objects with smooth or coarse surface Vacuum Object Table is specially customized for semi-conducting wafers, so influence from feeble air flowing to test object is eliminated in measurement Application Cases Measurement and analysis for various products, components and materials`surface form and profile characteristics, such as flatness, roughness, waviness, appearance, surface defect, abrasion, corro- 应用领域 sion, gap,hole, stage, curvature, deformation, etc. Surface form Air-Bearing Isolation System Built-in air bearing isolation system can isolate the vibration. Air pressure of the machine can be supplied by air compressor or inflators. Sonic Vibration Isolation The shell is separated from the internal motion unit, which effectively isolates the transmission of sound wave vibration. Easy Level Improve the re-establishment accuracy and adjust stripe width by adjusting tilt of object table Convenient joystick Easy to control X/Y/Z movement, speed and light source brightness; Emergency stop button Magnetic diamond head Pyramid angle Diffractive component Profile curve Engine blade of aircraft Surface roughness Profile sizes

Open the catalog to page 1

3D Optical Surface Profilometer SuperView W1 3D Optical Surface Prof ilometer White Light Interferometry It is used for measurement and analysis of surface roughness and profile of precision components from industries of semi-conductor, 3C Electronics, ultraprecise machining, optical machining, Nano 3D Surface Form and Roughness micro-nano materials, micro-electro-mechanical system. Super smooth lens Unique re-establishment algorithm can filter noises of surface of test object. Cut sheet, coated sheet, wafer IC Roughness, microcosmic Sapphire screen, glass screen, Ink screen Roughness,...

Open the catalog to page 2

3D Optical Surface Profilometer 3D Optical Surface Profilometer Video System Objective Lens Standard Field of View Lens Turret Size Travel Range Control Method Z Stroke Scanning Range Surface Form Repeatability*1 microscopy on 2-in-1 Hybrid 3D Optical Profilometer. Control method series & WT series, and can independently identify the type of model. Especially, the software Weight Size(L*W*H)mm Motorized 5 holes turret ment,It can perfectly adapt to all microscopic 3D machine models of CHOTEST W series & VT Load Capacity can automatically switch scanning modes between white light...

Open the catalog to page 3

Optical Measuring Instruments *1 Use EPSl mode to measure Sa 0.2nm silicon wafer in the laboratory environment; Single stripe, 80um filter for full field of view. *2 Measure Sa 0.2nm silicon wafer in a laboratory environment according to the ISO 25178. *3 Measure standard 5|jm steps height block in a laboratory environment according to the ISO 1060-1:2009. *4 When the software noise evaluation is 4nm<3a<10nm, the Roughness RMS repeatability is revised down to 0.015nm, the Step height measurement accuracy is revised down to 0.7%, and the step height measurement repeatability is revised down...

Open the catalog to page 4All Chotest Technology Inc. catalogs and technical brochures

-

PRODUCT CATALOGUE

67 Pages

-

WR50 Rotary Axis Clibrator

4 Pages

-

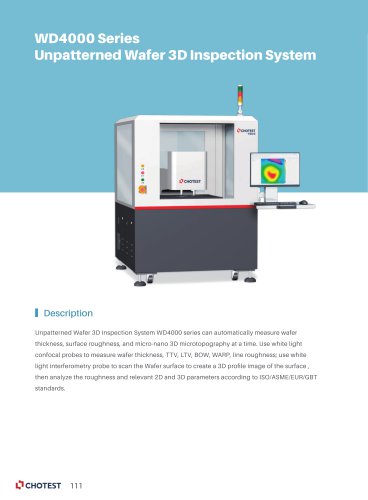

WD4000 SERIES

4 Pages

-

PO40 PO40L PO60

2 Pages

-

SJ5800-100 SJ5800-200

4 Pages

-

SJ5900-100 SJ5900-200

4 Pages

-

VX1060 VX1100

1 Pages

-

Laser Interferometer SJ6000

4 Pages

-

Profilometers SJ57 Series

8 Pages

-

Profilometer SJ5700 Series

4 Pages