Catalog excerpts

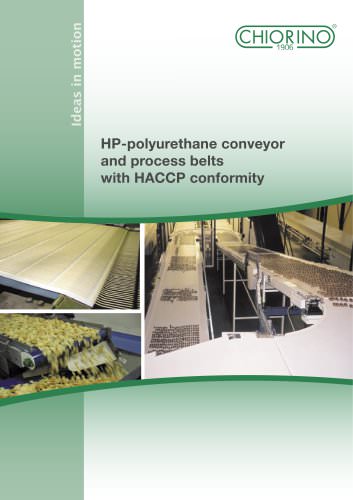

HP-polyurethane conveyor and process belts with HACCP conformity

Open the catalog to page 1

HPpolyurethane conveyor and process belts with HACCP conformity The CHIORINO HP POLYURETHANE conveyor and process belts are product leaders for the food industry in terms of performance and durability. Thanks to the sophisticated production technology and the special polyurethane polymers used, the CHIORINO “HP” belts PREVENT BACTERIA FROM PROLIFERATING and ensure HIGH PHYSICAL-CHEMICAL-MECHANICAL PERFORMANCE. The increasingly stringent regulations on the subject of food hygiene and safety have forced plant manufacturers to choose components that are totally reliable from the point of view...

Open the catalog to page 2

At the forefront of hygiene and food safety The HP POLYURETHANE belts are CHIORINOʼs answer to the growing demand by food system manufacturers for components that ENSURE TOTAL HYGIENE and that DO NOT CONTAIN BIOCIDE ADDITIVES that could migrate from the surface and contaminate the product being conveyed. Main COMPETITIVE ADVANTAGES CHIORINO HP POLYURETHANE belts: Prevent the proliferation of bacteria Do not contain biocide additives HACCP, FDA and 2005/79/CE conformity Excellent resistance to washing High resistance to chemical agents Optimal resistance to vegetable oils High resistance to...

Open the catalog to page 3

CHIORINO HP belts can be subjected to continuous washing systems with hot water and detergents without undergoing any deterioration. CHIORINO HP POLYURETHANE belts conform to the concept of HACCP (Hazard Analysis and Critical Control Points) and to the FDA (cfr21§ 177.2600) and 2005/79/CE regulations relating to food hygiene and safety. The special calendering technology combined with the know-how and the quality achieved by CHIORINO guarantee an end-product with particularly high performance levels. Thanks to the sophisticated productive system of CALENDERING, the SURFACE of the HP...

Open the catalog to page 4

Change of mechanical properties HP does not only mean HACCP. CHIORINO HP POLYURETHANE belts over and above guaranteeing compliance with the HACCP concept ensure HIGH PHYSICAL-CHEMICAL-MECHANICAL PERFORMANCE compared to the traditional belts in polyurethane and are prized in particularly dicult applications, even outside the food sector. 1. Resistance to hydrolisis cleaning systems Time Test effected in ultimate work conditions on trial machinery in the CHIORINO laboratories Change of mechanical properties The HP POLYURETHANE belts are very resistant to exion retaining their elastic...

Open the catalog to page 5

Blue HP belts In response to the most recent trend of the food and agro-industrial industry CHIORINO has made a complete range of belts in BLUE HP POLYURETHANE, which in addition to the characteristics of the white HP belts oer the following advantages: ▸ they guarantee an optimal visual contrast with the material being conveyed. The raw dough, the products to be baked in the oven and the fruit and vegetables stand out better on the blue belts compared to the white or traditional green belts. In addition blue enables one to see any residues during the cleaning operations; ▸ they reduce the...

Open the catalog to page 6

Production program 1M5 U0-U2 HP W A 1M5 U0-U2 HP W S A 1M5 U0-U2 HP D W A 1M5 U0-U2 HP VL blue A 2M5 U0-U0 HP A 2M5 U0-U2 HP W A 2M5 U0-U2 HP W S A 2M5 U0-U2 HP PN W A 2M5 U0-U2 HP VL blue A 2M5 U0-U2 HP PN blue A 2M5 U2-U2 HP VL blue A The technical data of this table have been formulated under normal environment conditions. They are subject to alteration without notice. (1) Minimum roller diameter is dependent on the joint recommended by CHIORINO (2) Elastic belts ʻELʼ: pull for 8% elongation (3) Conveying surface coecient of friction: LF low MF medium HF high : knife edge TEXTILE CARCASS...

Open the catalog to page 7

United Kingdom Chiorino Parma Chiorino Veneto South Africa WORLDWIDE CHIORINO

Open the catalog to page 8All CHIORINO catalogs and technical brochures

-

Company Profile

34 Pages

-

Timing belts

44 Pages

-

General catalogue

38 Pages