Catalog excerpts

Meets Industry Demands lor Precise Performance at Maximum Efficiency The two most important criteria when specifying a custom heavy-duty fan are efficiency and reliability. Air handling systems are increasing in complexity with the addition of more restrictive emission controls and air cleaning devices. While the result has been a cleaner environment, system pressure requirements have risen significantly. As these requirements increase, greater levels of energy are needed to force the air or gas through the system. Operating efficiency of the fan has become much more critical. Every...

Open the catalog to page 2

Individually Computer Engineered and Sized To cover the widest range of system requirements, Chicago offers a full family of airfoil and backwardly curved fan designs with overlapping performance envelopes. To maintain high efficiency and maximum economy, the system’s pressure and flow requirements are matched to one of eleven wheel designs with varying rotor widths and diameters. The selected fan is then sized to exact duty requirements. No more, no less. Wheels are available with either Chicago’s proven hollow airfoil blades for clean air, or solid backward curved or backward inclined...

Open the catalog to page 3

Greater Design Speed and Accuracy As no two systems are exactly alike, no two fans should be exactly alike. That's why Chicago maintains the most comprehensive in-depth computer programs in the industry. Selection data, performance curves, sound data, physical data, dimensions and more are all computer processed. Not only is fan selection faster and more accurate, alternative selections are readily available. Options can easily be itemized and quoted separately for further consideration. To provide more immediate and personal design assistance, every Chicago Sales Office is tapped into this...

Open the catalog to page 4

Fans designed for field erection are first fully assembled at the factory to guarantee accurate fit-up at the jobsite. IHFOIL 1 BMCIWABDLlf CURVED A. Chicago builds their own inlet vane assemblies adding construction and control features to match each application. b. Packaged arrangements allow single piece shipments and dramatically reduce installation time and cost. C. In-house fabrication allows for better quality control. D. Rotatable fixtures assure uniform positioning and welding.

Open the catalog to page 5

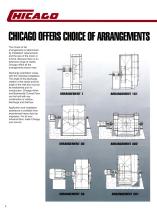

CHICAGO OFFERS CHOICE OF ARRANGEMENTS The choice of fan arrangements is determined by installation requirements and the size of the motor or turbine. Because there is an extensive range of needs, Chicago offers all the arrangements shown here. Discharge orientation varies with the individual installation. The angle of the discharge, rotation of the wheel and the angle of the inlet box must all be established prior to construction. Chicago Airfoil and Backwardly Curved Fans can be built with any combination of rotation, discharge and inlet box. Application and installation assistance is...

Open the catalog to page 6

Direction of rotation and discharge are viewed from the drive side of the fan. On dual driven units, the drive side is always the higher horsepower drive. ARRANGEMENT 7S1 ARRANGEMENT 7D2 INLET BOX POSITIONS Positions are always determined from the drive side of the fan.

Open the catalog to page 7

Setting the Standard For Quality Sales Offices Throughout North America Chicago Blower Fans are also manufactured worldwide: Your Primary Source For Every Fan Requirement General Duty - Industrial Duty - Heavy Duty - Argentina, Australia, Brazil, Chile, China, Colombia, Denmark, Germany, Greece, Holland, Hong Kong, India, Fans to handle dirty and corrosive environments Custom engineered fans for specific applications Indonesia, Israel. Italy. Japan, Korea, Malaysia, New Zealand, Norway, Philippines, Portugal, Saudi Arabia, Singapore, South Africa, Spain, Sweden, Thailand, Taiwan, Turkey,...

Open the catalog to page 8