Catalog excerpts

ACCEPTANCE INSPECTION When goods are received, customers shall inspect the package if there is any damage. When the package is unpacked, customers are advised to inspect carefully if there is any mechanical damage on the product and if the certificate, barcode sticker and label are corresponding to the product. For a fine product, there is no scratch or crack on ceramics and also there should be without any abnormal noise when shaken by hands. Power frequency withstand voltage test Customers are recommended to do Power frequency Withstand Voltage Test at least one time on every vacuum interrupter before assembling. Before the test, however, the products should be wiped clean with dry cloth or with alcohol. The test is required to be done as follows: at rated full stroke, 70% of rated power frequency withstand voltage is applied to the both ends and held for one minute and then increased to 100% of the voltage for another one minute. If there is no trip and the indicator does not fluctuate inappropriately, the product is qualified. However, it is permitted if the spark or flashover happens occasionally due to the spurs inside the VI. If there is any product unqualified, please contact our sales department instantly to solve this problem. APPLICATIONS AND OPERATION Under service condition, the operating voltage and current should not exceed the rating values of vacuum interrupters. The vacuum level of vacuum interrupters should be inspected periodically through the test of power frequency withstand voltage. It should be done as follows: Rated short time (1 min) power frequency withstand voltage is applied on vacuum interrupters when contacts are open at full stroke (circuit breakers are open). Permanent discharge is not allowed; otherwise, the vacuum interrupters should be replaced. While circuit breakers are closed and simultaneously the erosion mark on movable stem gets disappeared, that is to say the contact erosion is over 3mm, and the vacuum interrupter goes beyond their life cycles and should be replaced immediately. APPENDIX, PACKING TRANSPORTATION AND STORAGE Appendix: one copy for Service guide and certificate of quality. Packing and transportation Before delivery, vacuum interrupters should be packed in accordance with the standards related to packages. Signs such as “Upwards”, “keep away from moisture”, “Fragile, Handle with care” should be clear and observable. Well-packed vacuum interrupters are suitable for transportation by truck, train, and aircraft. If by truck, acceptable turbulence compares to the speed 20KM/H on Class III Road; packages should be handled with care; No turnover or strike. Storage Condition: dry, well-ventilated and non-corrosive gas warehouses at -30°C~ 40°C. Limit: 20 years (no mounting). MAINTENANCE When packages are removed, vacuum interrupters should be roasted in oven for 48 hours at 70°C~80°C before usage if there is any moisture. Regularly, vacuum interrupters should be inspected and cleaned if there is any pollution by moisture or erosive gas because of no use for a long term. If the products are damped, storage conditions should be improved after the process according to 7.1 Under service condition, routine maintenance should cover: a) Power frequency withstand voltage; c) Surface condition; MAIN TECHNICAL PERFORMANCE Specifications and dimensions of vacuum interrupters should meet up with the requirements of formal product catalog. The specifications and mechanical performance of switchgear should satisfy the requirements on catalog. Before assembling, the vacuum interrupter should be cleared by cotton or silk with alcohol; meanwhile, the conducting rods and the connections should be cleared so as to ensure the vacuum interrupters in good contact with the switchgears. Vacuum interrupters should be assembled and adjusted in according to assembling requests of circuit breakers; but all mechanical parameters of the vacuum switches should meet up with the requirements of vacuum interrupters. It is never allowed to strike or hit vacuum interrupters while assembling or adjustment. When the plate is connected to the fixed terminal of vacuum interrupters with bolts, screw-in depth into the vacuum interrupters should be less than the depth of thread marked on the technical drawings of interrupters. As showed in Pic. 1 and Pic.2, in order to ensure the safety of metal bellows, when mounting the insulation push rod, the movable stem should be fixed up with a clamper through the slot (if there is any). If there is no slot or vacuum interrupters are used for the making of embedded poles, please take reference to the antitwist torque force given in its specifications. When the tightening force is smaller than the anti-twist torque force, a torque spanner should be used to tighten the insulated push rod. Detailed tightening torque values are given in the form attached. When the tightening torque force is higher than the anti-twist torque force, the insulating push rod should be mounted in the manner showed in Pic.2, which will prevent from the moving of the stem and the twisting of the metal bellows. It is suggested that thread glue shall not be used for the assembling of insulation drive rod, which will prevent from the heli coil is taken out while screwing out the drive rod. If thread glue is applied, do not take out the drive rod. In assembling of drive rod, screw-in depth shall be no less than 1.5 times of the thread diameter. In operating conditions, a guide device is strongly requested so that the movable stem moves in axial direction and twists no bellows. It should be noticed that the axes of the movable stem is perpendicular to the fixed end plate. In mounting, the ceramic shells of vacuum interrupters should bear no apparent horizontal stress. Vacuum interrupters should not be removed repeatedly, which may cause severe damages on connection threads; and in order not to twist or damage metal bellows, it is never allowed to twist the movable stem or excessively press the metal bellows. Thread locker should not be applied while mounting insulation push rod, which will prevent from pulling out threaded loop when the push rod has to be screwed out. If thread locker is used, please try not to pull out the insulated push rod. While installing the insulation push rod, screw-in depth should not be less than 1.5 times of nominal diameter of the movable stem.

Open the catalog to page 1All Chengdu Xuguang Electronics Co. catalogs and technical brochures

-

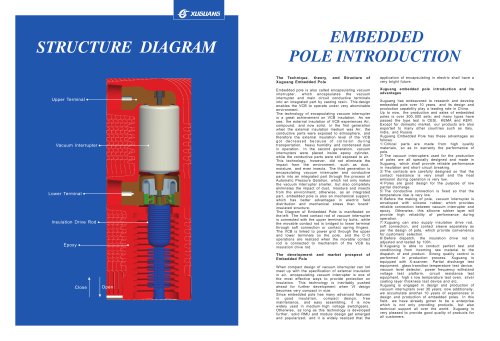

Embedded Pole

2 Pages