Catalog excerpts

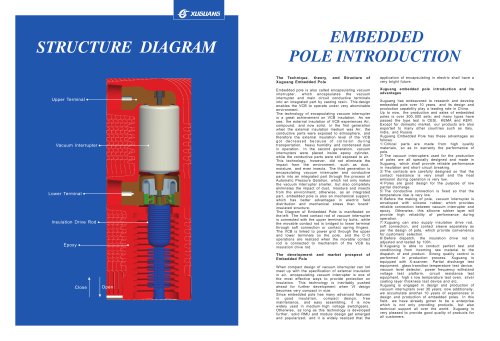

STRUCTURE DIAGRAM EMBEDDED POLE INTRODUCTION Upper Terminal Vacuum Interrupter' Lower Terminal The Technique, theory, and Structure of Xuguang Embedded Pole Embedded pole is also called encapsulating vacuum interrupter, which encapsulates the vacuum interrupter and main circuit conductive terminals into an integrated part by casting resin. This design enables the VCB to operate under very abominable environment. The technology of encapsulating vacuum interrupter is a great achievement on VCB insulation. As we see, the external insulation of VCB experiences Air, compound, and now solid. In the first generation when the external insulation medium was Air, the conductive parts were exposed to atmosphere, and therefore the external insulation level of the VCB got decreased because of collision during transportation, heavy humidity and condensed dust in operation. In the second generation, vacuum interrupters were placed inside epoxy cylinder, while the conductive parts were still exposed to air. This technology, however, did not eliminate the impact from the environment, such as dust, moisture, and even insects. The third generation is encapsulating vacuum interrupter and conductive parts into an integrated part through the process of Automatic Pressure Gelation, which not only makes the vacuum interrupter smaller, but also completely eliminates the impact of dust, moisture and insects from the environment; otherwise, as an integrated part, embedded pole is also an mechanical support, which has better advantages in electric field distribution and mechanical stress than board-insulated structure. The Diagram of Embedded Pole is manifested on the left: The fixed contact rod of vacuum interrupter is connected with the upper terminal by bolts, while the movable contact rod is bridged to lower terminal through soft connection or contact spring fingers. The VCB is linked to power grid through the upper and lower terminals on the pole, and the C-0 operations are realized when the movable contact rod is connected to mechanism of the VCB by insulation drive rod. The development and market prospect of Embedded Pole When compact design of vacuum interrupter can not meet up with the specification of external insulation in air, encapsulating vacuum interrupter is one of the most effective ways to provide protection on insulation. This technology is inevitably pushed ahead for further development when VI design becomes very compact in size. Since embedded pole has many advanced features in good insulation, compact design, free maintenance, and easy assembling, it is now widely used in medium-high voltage switchgears. Otherwise, as long as this technology is developed further, solid RMU and module design get emerged and popularized, and it is widely realized that the application of encapsulating in electric shall have a very bright future. Xuguang embedded pole introduction and its advantages Xuguang has endeavored to research and develop embedded pole over 10 years, and its design and production capability play a leading role in China. Up to now, the production and sales of embedded poles is over 300, 000 sets; and many types have passed the type test in CESI, KEMA and KERI. Except for domestic market, our products are also exported to many other countries such as Italy, India, and Russia. Xuguang Embedded Pole has these advantages as follows: 1) Critical parts are made from high quality materials, so as to warranty the performance of pole. 2) The vacuum interrupters used for the production of poles are all specially designed and made in Xuguang, which shall provide reliable performance in insulation and short-circuit breaking. 3) The contacts are carefully designed so that the contact resistance is very small and the heat emission during operation is very low. 4) Poles are good design for the purpose of low partial discharge. 5) The conductive connection is fixed so that the temperature rise is very low. 6) Before the making of pole, vacuum interrupter is enveloped with silicone rubber, which provides reliable connection between vacuum interrupter and epoxy. Otherwise, this silicone rubber layer will provide high reliability of performance during operation. 7) Xuguang can also supply insulation drive rod, soft connection, and contact sleeve separately as per the design of pole, which provide convenience for customers’ selection. 8) Before dispatch, the insulation drive rod is adjusted and tested by 100%. 9) Xuguang is able to conduct perfect test and conditioning from incoming raw material to the dispatch of end product. Strong quality control is performed in production process. Xuguang is equipped with X-scanner, Partial discharge test equipment, glass transition temperature test device, vacuum level detector, power frequency withstand voltage test platform, circuit resistance test equipment, high & low temperature test oven, silver coating layer thickness test device and etc. Xuguang is engaged in design and production of vacuum interrupters over 30 years; now additionally, we accumulate another 10 years of experiences in design and production of embedded poles. In this field, we have already grown to be a enterprise which is not only providing products, but also technical support all over the world. Xuguang is very pleased to provide good quality of products for all customers.

Open the catalog to page 1

MAIN USAGE AND SERVICE CONDITION Xuguang Embedded Pole, which enables circuit breakers, load break switches and vacuum contactors to break and make currents, are widely servicing in rural and urban power distribution systems and many other fields that need to break circuits frequently such as electricity, machinery, metallurgy, mining, and railways. Service condition Ambient Air temperature Indoor highest temperature: +40°C; outdoor highest temperature: +40°C; Indoor lowest temperature: -25°C; outdoor lowest temperature: -40°C. Altitude above sea level: normally used below 1000m; If there...

Open the catalog to page 2All Chengdu Xuguang Electronics Co. catalogs and technical brochures

-

Vacuum Interrupter

2 Pages