Catalog excerpts

Reliability, Performance and Value The MR agitator’s gearbox is a proprietary, parallel shaft, helical gear design that features minimum 30,000 hour L-10 bearing life and an oversized output shaft for optimal performance and extended service life. Shaft speed selections are available from 7 to 380 rpm without the use of auxiliary reducers or electronic drives. When the MR gearbox is expertly matched with a wide variety of Chemineer impellers and other system components, MR agitators are capable of economically meeting your blending, dispersion, and other mixing needs. Gearbox proprietry...

Open the catalog to page 2

Global Availability and system components to changes in application requirements or operating environments. To support the global manufacturing footprint of our customers, MR agitators are available in all major global markets. MR agitator gearboxes, mountings and system components are also interchangeable with the Chemineer Model 20 HT and GT agitators enabling customers to readily adapt or upgrade their agitator drives With all of its versatility, MR agitators can become your global process system standard helping drive efficiencies in procurement and reduce maintenance costs and...

Open the catalog to page 3

Features Benefits In-Tank Coupling and Steady Bearing Options

Open the catalog to page 4

Features Benefits

Open the catalog to page 5

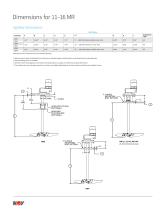

Agitator Dimensions Bolt Pattern Dimensions are for reference only. See assembly drawing. 1 Agitator output speed, shaft diameter and extension, impeller design and other features not shown built to suit application. 2 Alternate flange sizes are available. 3 Both the D and P style agitators come with a steel base plate as an option. See IOM for base plate dimensions. 4 These dimensions are only approximations, and may vary slightly depending on the motor options and the motor supplier chosen. W-, AUXILIARY LIP SEAL (OPTIONAL) AUXILIARY STUFFING BOX (OPTIONAL) MOUNTING BOLT PATTERN

Open the catalog to page 6

Bolt Pattern Dimensions are for reference only. See assembly drawing. 1 Agitator output speed, shaft diameter and extension, impeller design and other features not shown built to suit application. 2 Alternate flange sizes are available. 3 Both the D and P style agitators come with a steel base plate as an option. See IOM for base plate dimensions. 4 These dimensions are only approximations, and may vary slightly depending on the motor options and the motor supplier chosen. (Non-Swivel Pedestal)

Open the catalog to page 7

Swivel Dimensions Typical Drive Assembly Swivel Dimensions Drive assembly pivots at top of pedestal to allow change out of mechanical seals. See IOM for special motor conduit instructions. Motor Dimensions Frame Size Dimensions are for reference only. See assembly drawing. Drive Assembly Dimensions Case Size

Open the catalog to page 8

Case Size Motor Dimensions Dimensions for 13 and 14 MR Typical Drive Assembly Swivel Dimensions Drive assembly pivots at top of pedestal to allow change out of mechanical seals. See IOM for special motor conduit instructions. Frame Size Dimensions are for reference only. See assembly drawing. Drive Assembly Dimensions Case Size

Open the catalog to page 9

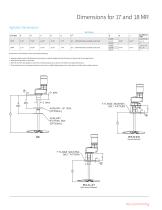

Swivel Dimensions Typical Drive Assembly Swivel Dimensions Drive assembly pivots at top of pedestal to allow change out of mechanical seals. See IOM for special motor conduit instructions. Motor Dimensions Frame Size Dimensions are for reference only. See assembly drawing. Drive Assembly Dimensions Case Size

Open the catalog to page 10

Case Size Motor Dimensions Dimensions for 17 and 18 MR Typical Drive Assembly Swivel Dimensions Drive assembly pivots at top of pedestal to allow change out of mechanical seals. See IOM for special motor conduit instructions. Dimensions are for reference only. See assembly drawing. Drive Assembly Dimensions Case Size

Open the catalog to page 11

National Oilwell Varco has produced this brochure for general information only, and it is not intended for design purposes. Although every effort has been made to maintain the accuracy and reliability of its contents, National Oilwell Varco in no way assumes responsibility for liability for any loss, damage or injury resulting from the use of information and data herein. All applications for the material described are at the user’s risk and are the user’s responsibility. © 2016 National Oilwell Varco | AH Rights Reserved Bulletin 734 Rev 02 Corporate Headquarters 7909 Parkwood Circle Drive...

Open the catalog to page 12All Chemineer catalogs and technical brochures

-

ChemineerTM Impellers

4 Pages

-

Production Services

16 Pages

-

Artificial Lift Technologies

12 Pages

-

Mixing Technologies

12 Pages

-

Ameron Victorian Series Poles

28 Pages

-

Chemineer HT Agitators Brochure

10 Pages