Catalog excerpts

Ale SSA Siehc eR Lak 自 行 車 ・機 車・ 模 具 等 産業 ・ JB Riddists « AT Rie STAR : AE PINAR High-speed processing requirements for electronic industries, such as Aero- space, bicycle, locomotive, mold and other industries. The insert seat has a fine-tuning structure, which makes the insert adjust the p level, and the cutter is tightly combined with the, insert seat to prevent detachment during high-speed rotation. The cutting process can also effectively remove chips and prevent surface damage during cutting. coolant to efficiently cool the work-piece cutter life. FoR ASG) A Sho) MSP RRS - NASB PN ER...

Open the catalog to page 3

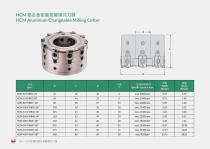

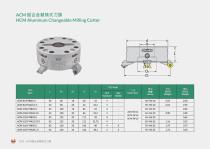

HCM Aluminum Changeable Milling Cutter

Open the catalog to page 4

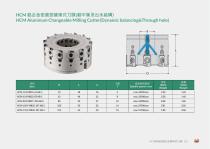

HCM 鍋 合 金 密 歯 型 替 換 式 刀 頭 ( 動 平衡 肥 出 水 結構 ) HCM Aluminum Changeable Milling Cutter(Dynamic balancing&Through hole)

Open the catalog to page 5

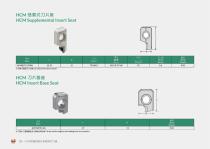

HCM-PCD刀 月 座 HCM PCD Insert Seat Polycrystalline Diamond If have the special angle need, please contact us. Ifhave the special angle need, please contact us.

Open the catalog to page 6

HCM-PCDJJFE& HCM PCD Insert Seat #8 7)F Single crystal diamond: Single crystal diamond

Open the catalog to page 7

HCM ##2x AE HCM Supplemental Insert Seat ※ 可 自 行 搭 配 刀 月 材質 Can collocation insert material. JJHK#E Insert Base Seat 17 Can be used for weight or self-welding head of the material.

Open the catalog to page 8

7) FEAR insert holder screw Sonat both headed screw T-type wrench L-type wrench

Open the catalog to page 9

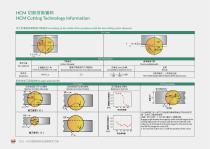

HCM 切削 技術 資料 HCM Cutting Technology Information hKLARERICH & 7S According to the width of the workpiece with the face milling cutter diameter 形式 Brie Part material E 建議 的 切 入 角 E The recommended cut-in angle 建議 刀 員 直 径 興 工 件 赴 度 比 Recommended tool diameterto workpiece width ratio eas a Choice suitable teeth 結果 Result SHABBY : 少 則 昌 起毛 下 More teeth easily deformed;less teeth easy to burr. Bite angle and tool life #9 Relation to Cutter Diameter Vf 一 と Relation to Cutter Position Relation to Tool Life 刀 Engage angle denotes the angle by which the full length of the "wa a cutting edge comes in...

Open the catalog to page 10

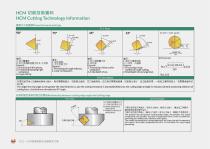

HCM 切削 技術 資料 HCM Cutting Technology Information TB Relation between the number of simultaneously engaged cutting edges and cutting force 形式 Re a HAY Bias OS1 時 0 or 1 edge in contact at same time. Bem LAB Only 1 edge in contact at any time. 2 edge in contact at any time. Normally, cutting width is considered to be appropriate with 70 to 80% of the cutter diameter engaged as shown in example D. However, this may not apply due to the actual rigidity of the machine or work piece, and machine horsepower. 建議 使用 刀 具 尽 寸 規 格 Recommended Cutter Spec. 71s Workpiece width range Suggest used the...

Open the catalog to page 11

HCM 切削 技術 資料 HCM Cutting Technology Information 環 控 刀 月 座 種 類 Chose the insert seat type 90° Piers General: 1. Processing of thin pieces. 2. Processing clamping rigid workpiece. 3. Large cutting. | は ALS 2. Large cutting parts. General: 1. Processing of deep cavity workpiece. 2. In the depth of cut. number of rough cutting. 2. Small depth of cut, large feed. General: 1. Processing of rough embryos. The larger the chip angle is, the greater the chip thickness is, and the cutting resistance is increased.Otherwise, the cutting edge strength is reduced. General processing selection of cutting...

Open the catalog to page 12

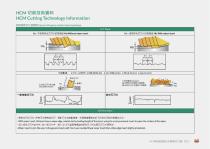

HCM Cutting Technology Information 如何 搭 配刀 月 座 類 型 How to Properly match insert seat type Hb : 使用 修 光 丸 刀 戸 的 粗糖 度 Hp: With wiper insert FA E3469) 7) Ae = Ha: Without wiper insert - With wiper insert: All insert have a wiper edge, relative to the beating height of the insert, using the most prominent insert to wiper the surface of the wiper.

Open the catalog to page 13

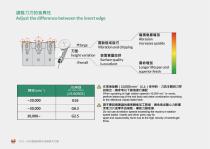

調整 刀 妨 的 差異 性 Adjust the difference between the insert edge BBaBiemM Abrasion fe S35 ALAR) Vibration and chipping increases quickly Surface quality Longer lifespan and superior finish RESULT RBCTBE When operating at high rotation speeds (10,000 min’ or more), perform balancing of the tool body and arbor combination according to the reference values listed here. Do not use at rotation speeds exceeding the maximum rotation speed stated. Inserts and other parts may fly apart and cause bodily harm due to the high velocity

Open the catalog to page 14

Materials examples

Open the catalog to page 15

Make sure the wedge and the insert are parallel. When installing wiper inserts (R300 or R500) be sure they are 0.03 ~ 0.05mm higher than the PCD insert.

Open the catalog to page 16

二 種 本 式 刀 座 可 替 換 The flute difference between inserts can be adjusted within 0.005mm. Covered within to decrease wind resistance and increase efficiency. The arbor and cutting head is mounted tightly for increased precision. The aluminum alloy cutting head is anod

Open the catalog to page 17

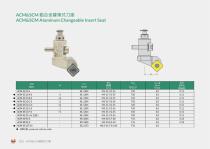

ACM 888 & Sia xt JGR HCM Aluminum Changeable Milling Cutter Insert Seat

Open the catalog to page 18

Insert Seat

Open the catalog to page 19

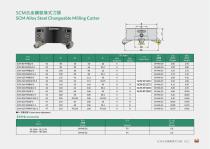

250 の 80の 刀 貞 結合 方 式 採取 内 包 覆 式 ・ 可 降 低 高速 加工 回 韓 時 産生 的 風 BRS EMS MRE 刀 具 興 刀 頭 定位 方 式 為 方 型 皿 配 ・ 利 於 刀 具 定位 力 頭 材質 採用 特殊 合金 鋼 ・ 可 提 高 剛性 ・ 三種 本式 刀 座 可共 換 ・ Covered within to decrease wind resistance and increase efficiency. The arbor and cutting head is mounted tightly to increase the

Open the catalog to page 20

SCM 合 金 鋼 替 換 式 用 豆 SCM Alloy Steel Changeable Milling Cutter Insert Seat

Open the catalog to page 21

ACM&SCM #48 & Bihar ACM&SCM Aluminum Changeable Insert Seat @ - 2842 -produced order by order.

Open the catalog to page 22

Adjust Screw Fixed Screw G-Type Ring PL-Type Wrench PL-Type Wrench Adjust cutter height Bless Bie Fix adjust screw Adjust cartridge HERS Fasten

Open the catalog to page 25

#21 FA 7) Application Insert Pll 2 + iS Alloyed Steels Refractory Alloys Hard Material BIRRRE Cutting Condition: O— tH General Cutting @ 2) A) Interrupted Cutting

Open the catalog to page 26

#21 FF Application Insert eM 218 Alloyed Steels iMG Stainless Steels K EE Cast Iron + HUHRE Cutting Condition: Interrupted Cutting Polycrystalline diamond Uitra-hard microprogram Continuous Cutting Refractory Alloys

Open the catalog to page 27

#21 FA) Fi Application Insert | Sif Alloyed Steels ‘*PMGiE Stainless Steels TD BIHKRS Cutting Condition: Refractory Alloys 18 ff Hard Material Layer coating

Open the catalog to page 28

t) Bilik 6 Cutting Condition: Hard Material

Open the catalog to page 29

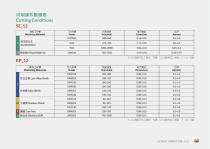

Cutting Conditions 被 加工 材質 Machining Materials S29) Low-Alloy Steels JARS Grade SERS fz(mm/rev) Cast Iron MLAS Machining Materials S28 Low-Alloy Steels FANT S82! : N38 | SCMii FADD

Open the catalog to page 30

Cutting Conditions SE 12 RIL Machining Materials Machining Materials A fifi Alloy Steels 7 $8 2 Stainless Steels (4 #238 Cast Iron Nh) 紹 合 金 Aluminum&Al

Open the catalog to page 31All CHAIN HEADWAY catalogs and technical brochures

-

PCD & PCBN PRECISION INSERT

24 Pages

-

STH&TPL Tapping holder Series

20 Pages

-

Angle Head Series

24 Pages

-

PNER Collet Chuck Series

20 Pages

-

DP Anti Vibration Series

28 Pages

-

SSP M405 Chamfering Series

16 Pages

-

Mini End Mill Cutter Series

16 Pages

-

CHAMFERING CUTTER SERIES

28 Pages

-

SIDE MILLING CUTTER SERIES

24 Pages

-

DEBURRING TOOL

2 Pages

-

Turning Inserts

12 Pages

-

VOL.7

853 Pages