Catalog excerpts

Secure the flow and save energy Emotron FDU 2.0 AC drive

Open the catalog to page 1

Full control and reliable operation Emotron FDU 2.0 AC drives offer reliable, cost-efficient and user-friendly operation of your pumps, fans, compressors and blowers. Full control of flow and pressure ensures an optimized operation, with reduced energy consumption and less downtime. The Emotron FDU also protects your equipment from damage and unnecessary wear. With all its functions included in a compact IP54 enclosure, the Emotron FDU is cost efficiently installed close to the application. The complete range covers motor powers from 0.55 to 3,000 kW. Protective starts and stops Protection...

Open the catalog to page 3

Save energy and optimize operation Save energy with speed control Sleep function optimizes operation Emotron FDU has been specially developed to regulate flow and pressure. Being able to continuously adapt the operation of your pumps and fans to match demand by controlling motor speed results in considerable energy and maintenance savings, compared to the use of throttling valves or dampers. The latter is like running a car at full throttle while controlling the speed using the brakes. Further energy savings, as well as reduced motor noise, are offered thanks to flux optimization. This...

Open the catalog to page 4

Multiple control for efficiency and reliability Using multiple pumps or compressors to keep a constant flow or pressure despite varying demands is a flexible, reliable and cost-efficient method. At all times you only use the number of pumps or compressors needed and thus the amount of energy required. An Emotron FDU controls up to seven drives without PLCs or other external equipment. When, for example, one pump reaches its limit, or when the demand decreases, the Emotron FDU starts or stops more pumps. The pressure control is done using the built-in PID process regulator. Which pumps to...

Open the catalog to page 5

User-friendly and reliable operation Emotron FDU 2.0 offers several user-friendly features that make both the operator’s and the installation engineer’s work easier and more reliable. Your own process language Several process values and system parameters are available via the communication interface, including current, voltage, shaft power, energy consumption and operating time. In addition to selecting the language to be displayed, you can easily set operation parameters in the units of your specific process, for example m³/s, bar or Pascal. No confusion, no time spent on translation and...

Open the catalog to page 6

Operation parameters can be set in your own process units – m³/s, bar, Pascal, etc. This makes monitoring easier and more reliable. Built-in programming blocks such as timers and comparators allow you to customize functionality. Customized functionality Easy copying of settings Emotron FDU offers built-in programming blocks, such as logical functions, comparators and timers. This opens the way for customizing functionality according to your requirements. You can, for example, set the AC drive to automatically clean a pump using a timer. The pump is run at full speed for a certain time to...

Open the catalog to page 7

Cost-efficient and flexible installation Installing Emotron FDU 2.0 is cost-efficient and flexible. The compact format and IP54 classification means the units can be installed close to the application. Flexible cable connection reduces the need for tools and terminals. Compact IP54 for cost-efficient installation Emotron FDUs in the 0.55-132 kW range are compact wall-mounted units, all IP54 classified and just as protected against dust and water as an electric motor. They have a robust metal construction and can withstand harsh environments. You can install the units close to the...

Open the catalog to page 8

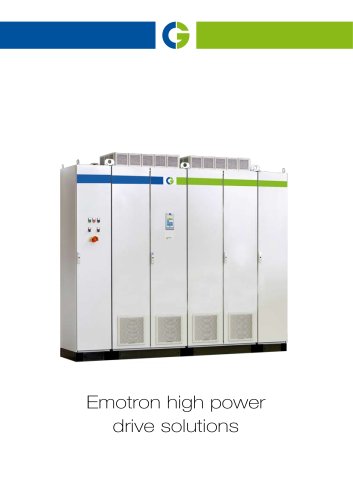

The 160-3,000 kW Emotron FDU models can be mounted in compact Emotron IP54 or IP23 cabinets with the control panel easily accessible on the front. The modular design offers reduncancy and easy servicing. Modular design The 160 to 3,000 kW Emotron AC drives are built-up with parallel connected 3-phase power modules. The modular design offers the possibility of redundancy operation. Operation can continue by temporarily running with reduced power capacity while one of the modules is out of operation. For very critical processes, you can even equip the system with an extra power module, to...

Open the catalog to page 9

Emotron FDU offers versatile communication options with the other control devices in the process or, for example, a control room. Options to customize your AC drive A number of options are available to let you customize Emotron FDU 2.0 functionality and fully utilize the product according to your needs. The compact option boards increase flexibility and cost-efficiency. They are easy to mount and up to four options can be combined. Up to three I/O boards can be mounted, each providing three relays and three digital inputs. Versatile communication options Like all Emotron products, the...

Open the catalog to page 10

nected to monitor motor temperature and give temperature feedback. You can also connect two PT100 sensors for motor protection and one PT100 for process feedback, measuring temperature without using a transducer. For units up to 46 A, an isolated motor thermistor input offers a low-cost solution approved in accordance with the DIN 44081/44082 standard. maintenance costs are lower since air conditioning is no longer needed to cool the cabinet and the surrounding room. Energy consumption can be reduced by recycling the heat produced by the AC drive. You will also reduce noise and heat in the...

Open the catalog to page 11

Detailed alarm codes simplify troubleshooting. Should a problem occur in the process, a full status report will help you to quickly identify the cause and take corrective measures. Simplified troubleshooting and maintenance Maintenance is simplified and downtime reduced thanks to a number of features. Fewer critical parts, which are easy to access, increase reliability. Detailed alarms help you identify the process problem quickly in order to take preventive action. Full status reports make troubleshooting easier Efficient alarm detection and detailed codes help you achieve reliable...

Open the catalog to page 12All CG Drives & Automation (former Emotron) catalogs and technical brochures

-

Emotron MSF 2.0 Softstarter

14 Pages

-

High Power in cabinets

4 Pages

-

Emotron TSA Softstarter

8 Pages

-

Emotron DCM control unit

8 Pages

-

Emotron EMX-P

2 Pages

-

Emotron EMX-R

2 Pages

-

Emotron EMX-D

2 Pages

-

Emotron MSF 2.0 Softstarter

5 Pages

-

Emotron AFE drives

8 Pages

-

Emotron VFX 2.0 AC drive

9 Pages

-

Technical catalogue AC Drives

36 Pages