Catalog excerpts

H i D R □ L i K PiSTDNLU FOMPA & MOTOR Bent Axis Piston Motor • Compact Design, • Economical Conception, • High Power Density, • High Efficiency, • High Rotating Speeds, following advantages; • High Pressure, • Good Starting Characteristics, • Optimized Weight and Size,

Open the catalog to page 1

Other Advantages of 2PBM Interchangeable and Compatible with other DIN Bent Axis Motors, Special Designed Pistons, One-Piece Piston with Piston Rings, For use in stationary and mobile applications, Compact motor design and extra durable parts, High Operational Reliability and High Starting Torque Extra Warranty with Wide Service 40° bent axis design giving high power, small overall dimensions, optimum efciency and economic design. Flange and shaft designed for direct mounting on the equipments. The xed displacement bent axis motors generates a hydraulic uid ow. It is designed for use in...

Open the catalog to page 2

Ordering Code of 2PBM Motors Motor Code Drive Shafts Mounting Flange Parallel Keyed Shaft: DIN 6885 2PBM Bent Axis Piston Motor, Fixed Displacement. Formulas Pump Output Flow HP = (Q ×P) / 1714 × E Eoverall = HPOut / HPIn X 100 Overall Efciency = Volumetric Eff. × Mechanical Eff. Pump Efciency Overall Efciency = Output HP / Input HP Pump Input Horsepower EOverall = EffVol. × EffMech. Pump Volumetric Efciency Volumetric Efciency = Actual Flow Rate Output (GPM) / Theoretical Flow Rate Output (GPM) × 100 EffVol. = QAct. / QTheo. X 100 Pump Mechanical Efciency Mechanical Efciency = Theoretical...

Open the catalog to page 3

Theoretical oil ow l/min at pump speed Maximum Speed - Without accessories - With accessories Motor Temperature

Open the catalog to page 4

Parallel Keyed Shaft: DIN 6885

Open the catalog to page 5

Compare Table of Torque

Open the catalog to page 6

Dimensions Size; Parallel Keyed Shaft: DIN 6885 6x6x32 Max. Continuous Pump Speed Max. Intermittent Pump Speed Weight without accessories Weight with accessories

Open the catalog to page 7

Dimensions Size; Parallel Keyed Shaft: DIN 6885 6x6x32 Max. Continuous Pump Speed Max. Intermittent Pump Speed Weight without accessories Weight with accessories

Open the catalog to page 8

Dimensions Size; Parallel Keyed Shaft: DIN 6885 6x6x32 Max. Continuous Pump Speed Max. Intermittent Pump Speed Weight without accessories Weight with accessories

Open the catalog to page 9

Dimensions Size; Parallel Keyed Shaft: DIN 6885 8x7x40 Max. Continuous Pump Speed Max. Intermittent Pump Speed Weight without accessories Weight with accessories

Open the catalog to page 10

Dimensions Size; Parallel Keyed Shaft: DIN 6885 8x7x40 Max. Continuous Pump Speed Max. Intermittent Pump Speed Weight without accessories Weight with accessories

Open the catalog to page 11

Dimensions Size; Parallel Keyed Shaft: DIN 6885 8x7x50 Max. Continuous Pump Speed Max. Intermittent Pump Speed Weight without accessories Weight with accessories

Open the catalog to page 12

Dimensions Size; Parallel Keyed Shaft: DIN 6885 8x7x50 Max. Continuous Pump Speed Max. Intermittent Pump Speed Weight without accessories Weight with accessories

Open the catalog to page 13

Dimensions Size; Parallel Keyed Shaft: DIN 6885 10x8x50 Max. Continuous Pump Speed Max. Intermittent Pump Speed Weight without accessories Weight with accessories

Open the catalog to page 14

Dimensions Size; Parallel Keyed Shaft: DIN 6885 10x8x50 Max. Continuous Pump Speed Max. Intermittent Pump Speed Weight without accessories Weight with accessories

Open the catalog to page 15

Dimensions Size; Parallel Keyed Shaft: DIN 6885 10x8x50 Max. Continuous Pump Speed Max. Intermittent Pump Speed Weight without accessories Weight with accessories

Open the catalog to page 16

Dimensions Size; Parallel Keyed Shaft: DIN 6885 10x8x56 Max. Continuous Pump Speed Max. Intermittent Pump Speed Weight without accessories Weight with accessories

Open the catalog to page 17

Dimensions Size; Parallel Keyed Shaft: DIN 6885 12x8x63 Max. Continuous Pump Speed Max. Intermittent Pump Speed Weight without accessories Weight with accessories

Open the catalog to page 18

Dimensions Size; Parallel Keyed Shaft: DIN 6885 12x8x63 Max. Continuous Pump Speed Max. Intermittent Pump Speed Weight without accessories Weight with accessories

Open the catalog to page 19

Quick Calculation Displacement (ccm/rev.) Diff. pressure (bar) Speed (rpm) Flow (lpm) Volumetric efficiency Mechanical-hydraulic efficiency Total efficiency (η t = η v x η mh) Address all questions regarding spare parts to your responsible Our Service Partner or the technical service department of the manufacture’s plant / factory for the 2PBM Bent Axis Motors. ÇELEBİ HİDROCEL OTOM. SAN. TİC. LTD. ŞTİ. Fevziçakmak mh. Aslım Cd. No: 53 C Karatay / KONYA Phone : +90 (332) 345 13 70 - +90 (332) 345 13 71 hidrocel@hidrocel.com.tr

Open the catalog to page 20

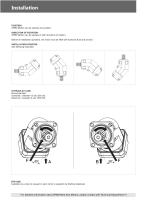

POSITION 2PBM Motors can be operate any position. DIRECTION OF ROTATION 2PBM Motors can be operate in both directions of rotation. Before of Installation operation, the motor must be filled with hydraulic fluid and air bled. INSTALLATION POSITION See following examples. HYDRAULIC FLUID Recommended ; Generally : between 15 and 200 cSt. Maximum : between 5 and 1600 cSt. FOR USE; Available via e-mail on request or each motor is supplied via Starting datasheet. For detailed information about 2PBM Bent Axis Motors, please contact with Technical Department !!!

Open the catalog to page 21

Complete Product Range Piston Pumps Piston Motors Fixed Plug-in P2 Connection M8x125 Woodruff key 3x6,5 NF E 27-653 NF R 124-04 (2 BOLTS)

Open the catalog to page 22

ÇELEBİ HİDROCEL OTOM. SAN. TİC. LTD. ŞTİ. Fevziçakmak mh. Aslım Cd. No: 53 C Karatay / KONYA Phone : +90 (332) 345 13 70 +90 (332) 345 13 71 Fax : +90 (332) 345 13 72 hidrocel@hidrocel.com.tr

Open the catalog to page 23All Celebi Hidrocel Ltd catalogs and technical brochures

-

PA Axial Piston Pumps

13 Pages

-

2PEM Bent Axis Motor

51 Pages

-

2PM Bent Axis Motor

44 Pages

-

Hydraulic Parts

12 Pages

-

PH Piston pump

15 Pages

-

2PMS Bent Axis Motors

18 Pages

-

2PE Bent Axis Pumps

28 Pages

-

2PS Bent Axis Pumps

21 Pages

-

2PBA Bent Axis Pumps

23 Pages