Website:

CEDRAT TECHNOLOGIES

Website:

CEDRAT TECHNOLOGIES

Catalog excerpts

E-LIFT3 PROJECT PROJECT OBJECTIVE The e-Lift3 project aims at developing an electromagnetically activated variable valve train component making it possible to optimize low engine size with 3/4 cylinder in a non-exclusive way. The system may be installed on the air intake or exhaust and on all or part of the valves of the target engine. This technology is part of a niche left open on the market between 2-stage and continuous variable valve timing systems, in terms of both cost and performances. It would help to support carmakers in complying with the European regulation of 95 g of CO2 per km in 2020 and in producing hybrid or I.C. engine vehicles with very low emission levels. Fuel savings of 9 to 12% for 4-cylinder engines and 6 to 8% for 3-cylinder engines equipped with e-Lift3 are expected. ■■ Fig1: Series of electromagnetic actuators CTEC CEDRAT TECHNOLOGIES CONTRIBUTION This year CTEC has invested in the design, manufacturing and test of electromagnetic actuators. In the framework of this automotive project CTEC has manufactured a series of electromagnetic actuators requiring means of production like a new winding tool for the fabrication of coils with wires from 80um to 3mm. This kind of tool will allow responsiveness to cope with the industrial projects requirements. To fit our customers’ needs, coiling technologies are now mastered: thermo bonded, round or rectangular coils, wire or PCB coils, overmolding… ■■ Fig2: Series of coils CTEC In order to characterize and test its coils and actuators, CTEC owns all necessary equipments: dielectric testers, impedance meter, network analyzer, force & torque sensors, position & speed sensors. The measured performances of the actuators are compared to the predictions provided by the soft tools such as Flux and Matlab / Simulink. In the framework of industrial and collaborative projects specific test benches are designed and used. Copyright © CEDRAT TECHNOLOGIES | E-LIFT3 - 01/2014 PARTNERS CTEC is working in collaboration with Valeo, PSA, Danielson Engineering, EMC, PRISM (Poly’Tech Orléans) and SATIE labs (ENS Cachan). For more information, please contact: CEDRAT TECHNOLOGIES 59 Chemin du Vieux Chêne - Inovallée 38246 Meylan Cedex - France actuator@cedrat-tec.com

Open the catalog to page 1All CEDRAT TECHNOLOGIES catalogs and technical brochures

-

DTT35XS-SI-2

3 Pages

-

XY Piezo stages heritage

8 Pages

-

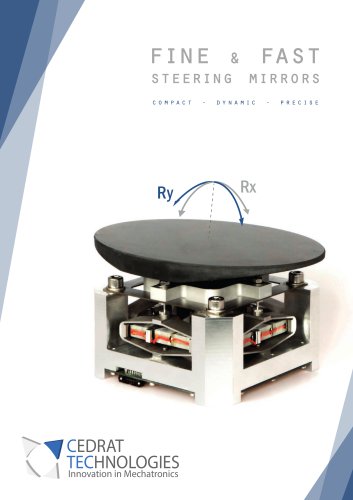

Fine and fast steering mirrors

10 Pages

-

Synchrotron Brochure

10 Pages

-

DTT35XS

3 Pages

-

TT60SM

3 Pages

-

APA600M

2 Pages

-

APA400M

2 Pages

-

APA200M

2 Pages

-

APA150M

2 Pages

-

APA100M

2 Pages

-

APA60SM

2 Pages

-

APA40SM

2 Pages

-

APA60S

2 Pages

-

APA50XS

2 Pages

-

APA35XS

2 Pages

-

APA150XXS

2 Pages

-

APA120S AND CAU10 AMPLIFIER

1 Pages

-

PPA20M

2 Pages

-

PPA40M

2 Pages

-

PPA40L

2 Pages

-

PPA60L

2 Pages

-

PPA80L

2 Pages

-

PPA120L

2 Pages

-

PPA40XL

2 Pages

-

PPA80XL

2 Pages

-

Piezo and magnetic products

77 Pages

-

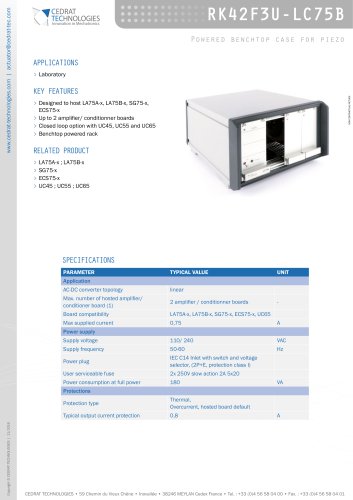

RK42F3U-LC75B

2 Pages

-

CA45

4 Pages

-

LA75A

4 Pages

-

LA75B

4 Pages

-

LA75C

3 Pages

-

SA75A

3 Pages

-

SA75B

3 Pages

-

SA75D

3 Pages

-

SP75A

3 Pages

-

UC65

3 Pages

-

UC55

3 Pages

-

UC45

2 Pages

-

CSA96

3 Pages

-

RK42F3U-LC24

2 Pages

-

ECSU10

2 Pages

-

ECS45

2 Pages

-

ECS75

3 Pages

-

ECP1000

2 Pages

-

ECP500

2 Pages

-

XY25XS

2 Pages

-

APA30uXS

2 Pages

-

PPA10M

2 Pages

-

FP7 SONO PROJECT

2 Pages

-

ASPIC PROJECT

1 Pages

-

viper cleansky project

2 Pages

-

MISAC PROJECT

2 Pages

-

PPSMPAB PROJECT

3 Pages

-

AEROPZT PROJECT

2 Pages

-

DYNXPERTS PROJECT

1 Pages

-

FluMIn3 projecT

1 Pages

-

CONTACTLESS TORQUE SENSORS

2 Pages

-

MC-SUITE Project

3 Pages

-

addendum

1 Pages