Website:

CDR Pompe

Website:

CDR Pompe

Catalog excerpts

Plastic Lined Magnetic Drive Centrifugal Pumps ETN EVO 50 ETFE Plastic and Fluoroplastic Lined Magnetic drive Horizontal - Single Stage - Centrifugal pumps Sub-ISO designed Lining: PP (Polypropylene), ETFE (Ethylene tetrafluoroethylene) Close-coupled execution Comply to : 2006/42/CE Design to : sub - ISO 2858 ATEX 100 © Directive 2014/34/EU Flanged UNI 1092-2 (ISO 7005-2 ) PN10RF type B slotted ANSI 150RF

Open the catalog to page 1

The ETN offer a wide range of materials The synchronous drive configuration is based on an outer magnet ring assembly couple with an inner magnet ring ETFE (Ethylene tetrafluo oethylene) These two magnet rings are locked together by the flux of attracting magnet poles flowing th ough the containment isolation shell. reliability, even under stress conditions Made with a reliable quality as the UTN Design Application fields New internal circualtion path for top but designed for smaller applications (low duty)

Open the catalog to page 2

3D VIEW Inner and Outer magnet are equipped with NdFeB (neodymium iron boron) or SmCo (samarium cobalt) permanent magnets. Patented cage magnet attachment guarantees stability during the operation of the pump. Top centerline discharge for air handling, self-venting. All wetted parts have an high chemical resistance employing a performing material as ETFE of at least 3 mm thickness. Alternative available materials for the Wetted parts: PP. ETFE Non-metallic double Isolation Shell configuration standard on all ETN series. ETN Evo: new internal circulation path to improve flushing and...

Open the catalog to page 3

CASING The ductile cast iron armour protects the fluoroplastic peripheral surfaces of the pump from pipe strain, vibration, external shocks and during the handling; moreover it allows the casing to be Vacuum resistant. IMPELLER ASSEMBLY The integral design of the impeller and inner magnet prevents any misalignment problem, reducing also the production cost. Standard back vanes reduce axial thrust and seal chamber pressures to guarantee an extraordinary bearing and seal life. ISOLATION SHELL ETFE on wet side externally reinforced by Polycarbonate reinforcement. Zero Eddy Current losses...

Open the catalog to page 4

Not binding data refers to water at room temperature. For specific performance curve contact CDR Pompe S.r.l.

Open the catalog to page 5

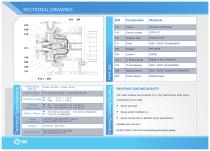

SECTIONAL DRAWING Technical Specifications Performances 2900 rpm PAINTING COATING QUALITY The metal surfaces are protected by a high performance three layers coating (240 micron total) • Epoxy zinc paint • Epoxy amidic modified viny • Epoxy enamel paint or aliphatic acrylic polyurethane Available upon request : EN ISO 12944-5 C5M and C5I protecting paint system grades

Open the catalog to page 6

L1 dimension is according to installed motor manufacturer Flanges dimensions according to UNI 1092-2 slotted ANSI 150 RF

Open the catalog to page 7

For further info, please visit www.cdrpompe.com C.D.R. Pompe S.R.L. Via R. Sanzio, 57 - 20021 Bollate (MI) - Italy Tel. +39029901941 Technical Characteristics The technical data and characteristics stated in this General Catalogue are not binding. CDR Pompe S.r.l. reserves the right to make modifications without notice. Therefore data, dimensions, performances and any other stated issues are indicative only and not binding. Anyway for any technical details you must require an up-to-date product technical card.

Open the catalog to page 8