Catalog excerpts

INTERNAL COMBUSTION ENGINES

Open the catalog to page 1

Designers of modern Internal Combustion engines face huge challenges to deliver power units which satisfy legislation and have competitive economy, performance and manufacturing cost. In particular, technology advances in fuel injection systems, alternative fuels, combustion systems, multi-fuel operation, downsizing and engine management coupled to ever shorter engine development timescales dictate that analysis is used widely to deliver optimum solutions. Although CFD analysis of in-cylinder flow and combustion has been established for over 30 years, the demands for increasing accuracy,...

Open the catalog to page 2

Pre & Post-Processing IC Engine in-cylinder analysis is particularly challenging in the respect that extremely complex physics occurs on short timescales and within a moving geometry. To aid the setup of these calculations and visualization and interpretation of results, CD-adapco has developed a pre- and post-processing environment, es-ice, to complement the STAR-CD solver. The pre-processor provides the user with all the tools necessary to generate computational meshes that accurately capture geometric details and to set up operating conditions and modeling choices including automatic...

Open the catalog to page 3

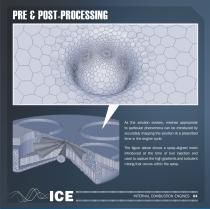

As the solution evolves, meshes appropriate to particular phenomena can be introduced by accurately mapping the solution at a prescribed time in the engine cycle. The figure above shows a spray-aligned mesh introduced at the time of fuel injection and used to capture the high gradients and turbulent mixing that occurs within the spray. INTERNAL COMBUSTION ENGINES 04

Open the catalog to page 4

LEFT Spray aligned meshes used to accurately model the fuel injection, spray evaporation and mixing processes INTERNAL COMBUSTION ENGINES 05

Open the catalog to page 5

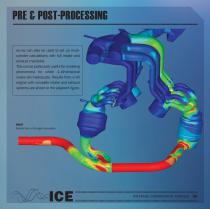

Pre & Post-Processing es-ice can also be used to set up multicylinder calculations with full intake and exhaust manifolds. This can be particularly useful for modeling phenomena for which 1-dimensional codes are inadequate. Results from a V6 engine with complete intake and exhaust systems are shown in the adjacent figure. RIGHT Results from a V6 engine calculation INTERNAL COMBUSTION ENGINES 06

Open the catalog to page 6

Physics The processes in IC Engines are extremely complex and include turbulence, heat transfer, 2-phase flow, evaporation and mixing, spray-wall impingement dynamics and films, chemistry and turbulence-chemistry interactions, real-gas effects, high-speed flow, radiation etc. To be able to calculate these routinely, accurately and robustly is a significant challenge. STAR-CD has been developed over many years to incorporate appropriate models and develop Best Practices for simulating these phenomena and extensive comparison with experimental data has been made to give confidence that...

Open the catalog to page 7

Spray Modeling ABOVE Diesel spray breakup modeling using VOF and LES The Lagrangian or Discrete Droplet Model approach to spray modeling has been developed for more than 30 years and has been used successfully for many different types of injector, in both diesel and gasoline engines. There has been tremendous evolution in fuel injection systems during this time, for example, common rail systems and multiple injections have become commonplace and injection pressures have increased by an order of magnitude; models in STAR-CD have also evolved to be able to model accurately the sprays produced...

Open the catalog to page 8

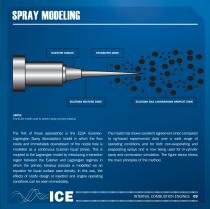

Spray Modeling INJECTOR NOZZLE transition zone eulErian mixture zone eulErian gas langrangian droplet zone ABOVE The ELSA model used to predict spray primary breakup The first of these approaches is the ELSA (EulerianLagrangian Spray Atomization) model in which the flow inside and immediately downstream of the nozzle hole is modelled as a continuous Eulerian liquid phase. This is coupled to the Lagrangian model by introducing a transition region between the Eulerian and Lagrangian regimes in which the primary breakup process is modelled via an equation for liquid surface area density. In...

Open the catalog to page 9

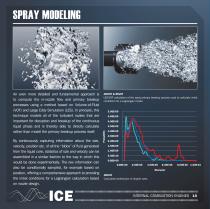

Spray MODELING An even more detailed and fundamental approach is to compute the in-nozzle flow and primary breakup processes using a method based on Volume-of-Fluid (VOF) and Large Eddy Simulation (LES). In principle, this technique models all of the turbulent scales that are important for disruption and breakup of the continuous liquid phase and is thereby able to directly calculate rather than model the primary breakup process itself. By continuously capturing information about the size, velocity, position etc. of all the “blobs” of fluid generated from the liquid core, statistics of size...

Open the catalog to page 10

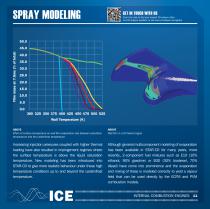

SPRAY MODELING ffbflKff Scan this code to find your nearest CD-adapco office * -IM-J ^ and CD-adapco resellers, or visit www.cd-adapco.conYglobal HHUVt ADUVt Effect of surface temperature on wall film evaporation rate between saturation Wall film in a Dl Diesel Engine temperature and the Leidenfrost temperature Increasing injection pressures coupled with higher thermal loading have also resulted in impingement regimes where the surface temperature is above the liquid saturation temperature. New modeling has been introduced into STAR-CD to give more realistic behaviour under these high...

Open the catalog to page 11

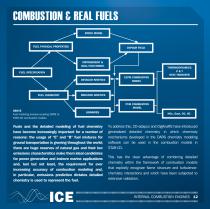

Combustion & Real Fuels Spray Model Fuel Physical Properties VAPOUR FIELD IMPINGEMENT & WALL-FILM MODEL FUEL SPECIFICATION DETAILED KINETICS FUEL chemistry ABOVE Fuel modeling process coupling DARS to STAR-CD combustion models ECFM COMBUSTION MODEL thermodynamics p&T heat transfer reduced kinetics PVM COMBUSTION MODEL LIBRARIES Fuels and the detailed modeling of fuel chemistry have become increasingly important for a number of reasons: the usage of “E” and “B” fuel mixtures for ground transportation is growing throughout the world; there are huge reserves of natural gas and their low...

Open the catalog to page 12

COMBUSTION I REAL FUELS Diesel combustion simulated with the ELSA and ECFM-CLEH models Depending on the combustion model being used, both library-based and on-the-fly chemistry using either detailed or reduced mechanisms are utilised. Cell-clustering techniques are available to reduce computation time for users that wish to solve chemistry on a cell-by-cell basis. A major advantage of using library-based methods is that the complex chemistry is performed just once for each fuel and thereafter used as a multidimensional look-up table, substantially reducing run time. In collaboration with...

Open the catalog to page 13All CD-adapco catalogs and technical brochures

-

Dynamics

24 Pages