Catalog excerpts

fako® Polishing paste 9311 Carbon Basalt Glas UFIW VDST-T0GU-T006-XHHX Acrylic glass is a noble material that is characterised by a number of special properties: practical ones such as resistance to breakage, resistance to ageing and light transmission as well as aesthetic ones such as transparency and beauty of the surface. Obviously a special material requires professional care. Our care products specially developed for Plexiglas help you to maintain the beauty and value of the material for years and decades. In comparison to silicate glass, two properties must be taken into particular consideration when caring for and cleaning acrylic glass. On the one hand the lower surface hardness and therefore higher susceptibility to scratches of acrylic glass, on the other hand the susceptibility of acrylic glass to solvents, especially organic ones. The use of incompatible polishing materials can cause stress cracks and matt surfaces. With fako® Polishing paste 9311 a care product is available, which is specially developed for the properties of Plexiglas, other acrylic glass and plastics Hazard statement and safety advice ✓ Read the label before use. EUH rates must be observed. Handling and storage ✓ Keep a tube tightly closed. Use only with good ventilation. Ensure good room ventilation also in the floor area (vapours are heavier than air). Store at temperatures between 10° and 20°C, protect from sunlight and heat. Always close the tube after use. Please keep the tube cap clean. ✓ Minimum shelf life 24 months after production at room temperature. Exclusion of liability ✓ This product information is based on the latest state of our knowledge and does not exempt the user from carrying out his own tests or taking his own precautions. We do not accept any liability for results from suggested applications, as conditions may change depending on the type of application. ✓ To the extent an exclusion of liability is permitted by law, the CBG Composites GmbH will not be liable for any loss or damage arising from this product, whether direct, indirect, special, incidental or consequential, regardless of the legal basis asserted, including warranty, contact, negligence or strict liability. CBG Composites GmbH Egerpohl 2 D-51688 Wipperfurth / Germany www.fako.de,www.cbg-composites.de The technical specifications of our products reflect the state of our knowledge at the time of printing. Therefore, the latest edition of the data sheet should always be used, as our experience and knowledge is constantly evolving. In case of doubt please contact us. The application shown is only exemplary and may vary in individual cases. It is therefore not liable. Our general terms and conditions apply, the latest version of which can be downloaded on www.fako.de

Open the catalog to page 1All CBG Composites GmbH catalogs and technical brochures

-

TDS CBG BioFiber Module

1 Pages

-

Basalt roving

1 Pages

-

Basalt fiber

1 Pages

-

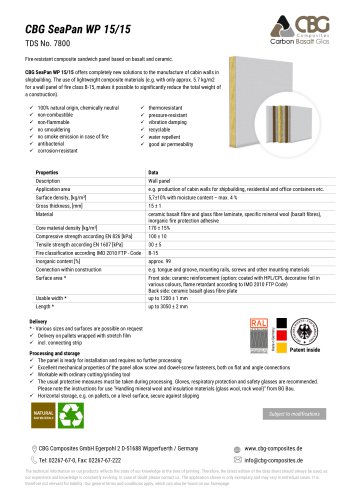

TDS CBG SeaPan WP 15/15

2 Pages

-

Cerammatrix Carbo

1 Pages

-

SilencePan 25/G

1 Pages

-

TDS FAKO-CBG 9303 fakopol

1 Pages

-

Cerammatrix 01-50

1 Pages

-

CorePan 15/G

1 Pages

-

SeaPan WP 15/G

2 Pages

-

CorePan 25/G

1 Pages

-

SeaPan WP 25/G

2 Pages

-

FireCore

1 Pages

-

FirePan 50/90

1 Pages

-

TDS CBG SeaPan WP 15/15

2 Pages

-

Certificate Module B

2 Pages

-

LifeRock MW-180

1 Pages

-

FirePan 25/30

1 Pages

-

SeaPan WP 15/G

2 Pages

-

SeaPan WP 15/15

2 Pages

Archived catalogs

-

OEM 50/60

2 Pages

-

OEM 57/150

2 Pages

-

FireStop

1 Pages

-

OEM 54/120

2 Pages

-

OEM 51/100

2 Pages

-

FiberMatrix

1 Pages

-

Basalt fabric

1 Pages

-

CBG-Übersicht

2 Pages

-

SeaPan WP 50/60

1 Pages

-

SeaPan WP 25/15

1 Pages

-

SeaPan WP 15/G

1 Pages

-

SeaPan WP 15/15

1 Pages