Catalog excerpts

Standard Sealing strip 3714 Carbon Basalt Glas UFIW CV8A-Y09Y-H00A-KU0U Anti-corrosion flexible one-sided self-adhesive butyl sealing strip, made of highly elastic, synthetic rubber (butyl) of soft rubber-like texture. It adheres reliably without heating. The butyl sealing strip is driven apart by the contact pressure, but due to its elasticity and plastic properties it penetrates into the smallest joints and unevenness and thus provides an optimum sealing. It can be drawn out to wafer-thin films by hand. Even high contact pressure level is not able to destroy the film. ✓ non-ageing ✓ UV-resistant ✓ tight towards water vapour ✓ seawater resistant Test results ✓ Leak tests with single riveted jointed receptacles have shown that a temperature resistance of -30°C to +80°C at a pressure of 0.5 bar is guaranteed. There were used dural sheets of 0.8 mm and 1 mm thickness with a rivet pitch of 25 mm. Processing and storage ✓ fako® Butyl sealing strip 3714 can be used immediately without special preparation, no priming required. It is recommended to use the sealing strip in a smaller width than the one of the riveted seam. After removing the protective film, the sealing strip is placed between the rivet or screw seams. In general, it is no longer necessary to drill through the sealing strip. ✓ 24 months after date of production at room temperature CBG Composites GmbH Egerpohl 2 D-51688 Wipperfurth / Germany www.fako.de,www.cbg-composites.de The technical specifications of our products reflect the state of our knowledge at the time of printing. Therefore, the latest edition of the data sheet should always be used, as our experience and knowledge is constantly evolving. In case of doubt please contact us. The application shown is only exemplary and may vary in individual cases. It is therefore not liable. Our general terms and conditions apply, the latest version of which can be downloaded on www.fako.de

Open the catalog to page 1

Standard Sealing strip 3714 Resistance to chemicals: At room temperature fako® Sealing strip 3714 are resistant to: thinned and concentrated hydrochloride acid thinned and concentrated sulfuric acid thinned and concentrated phosphoric acid thinned and concentrated chlorine sulfonic acid thinned and concentrated phenol sulfonic acid thinned and concentrated naphthalin soulfonsäure thinned and concentrated formic acid thinned and concentrated acetic acid thinned and concentrated caustic potash solution thinned and concentrated sodium hydroxide solution thinned and concentrated ammonia aqueous...

Open the catalog to page 2All CBG Composites GmbH catalogs and technical brochures

-

TDS CBG BioFiber Module

1 Pages

-

Basalt roving

1 Pages

-

Basalt fiber

1 Pages

-

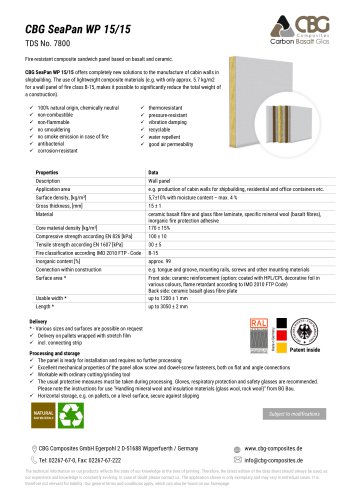

TDS CBG SeaPan WP 15/15

2 Pages

-

Cerammatrix Carbo

1 Pages

-

SilencePan 25/G

1 Pages

-

TDS FAKO-CBG 9303 fakopol

1 Pages

-

Cerammatrix 01-50

1 Pages

-

CorePan 15/G

1 Pages

-

SeaPan WP 15/G

2 Pages

-

CorePan 25/G

1 Pages

-

SeaPan WP 25/G

2 Pages

-

FireCore

1 Pages

-

FirePan 50/90

1 Pages

-

TDS CBG SeaPan WP 15/15

2 Pages

-

Certificate Module B

2 Pages

-

LifeRock MW-180

1 Pages

-

FirePan 25/30

1 Pages

-

SeaPan WP 15/G

2 Pages

-

SeaPan WP 15/15

2 Pages

Archived catalogs

-

OEM 50/60

2 Pages

-

OEM 57/150

2 Pages

-

FireStop

1 Pages

-

OEM 54/120

2 Pages

-

OEM 51/100

2 Pages

-

FiberMatrix

1 Pages

-

Basalt fabric

1 Pages

-

CBG-Übersicht

2 Pages

-

SeaPan WP 50/60

1 Pages

-

SeaPan WP 25/15

1 Pages

-

SeaPan WP 15/G

1 Pages

-

SeaPan WP 15/15

1 Pages