Catalog excerpts

Motor Grader Engine Engine Model Base Power (1st gear) – Net Base Power (1st gear) – Net (Metric) VHP Range – Net VHP Range – Net (Metric) VHP Plus Range – Net VHP Plus Range – Net (Metric) Moldboard Blade Width Weights Operating Weight, Typically Equipped

Open the catalog to page 1

Features Operator Station A revolutionary cab design gives you unmatched comfort, visibility and ease of use, so your operators can be more confident and productive. Structures, Drawbar, Circle and Moldboard Durable structures with fast and simple DCM adjustments save you service time. Shims and wear strips save you money and make it easy to maintain factory tightness of components for better grading results. Hydraulics Load sensing, proportional hydraulics mean operators can rely on consistent power. This precise, predictable implement response will save time and help assure quality work....

Open the catalog to page 2

The M Series Motor Grader represents a revolution in operational efficiency and overall productivity. The 16M is designed to help you build and maintain the haul roads needed to support maximum efficiency in mining operations. The 16M has set a new standard of quality to maximize your return on investment. 3

Open the catalog to page 3

Operator Station Comfort, productivity, advanced technology Visibility Good visibility is key to your safety and efficiency. Large windows make it easy to see the moldboard and tires, as well as behind the machine. A rear vision camera is available to enhance your sight lines to the rear of the machine. Comfort and Control Experience the most spacious, comfortable cab in the industry. Revolutionary joystick controls replace levers, so hand and arm movement is reduced by 78%, helping to reduce operator fatigue. Rocker switches and control levers are in easy reach. A standard Cat Comfort...

Open the catalog to page 4

Steering and Implement Controls Unprecedented precision and ease of operation Operators are more comfortable and productive with two electro-hydraulic joysticks. Electronically adjustable control pods help position operators for optimal visibility and proper operation. Joystick Functions The left joystick controls steering, articulation, return-to center, wheel lean, gear selection, left moldboard lift cylinder and float. The right joystick controls drawbar, circle and moldboard functions as well as electronic throttle control and manual differential lock/unlock. Joystick lean angle...

Open the catalog to page 5

Engine Power and reliability The Cat C13 engine with ACERT™ Technology gives you the performance to maintain consistent grading speeds for maximum productivity. Superior torque and lugging capability pulls through sudden, short-term load increases. ACERT Technology lowers combustion chamber temperatures and optimizes fuel combustion to generate more work output for your fuel cost. Variable Horsepower (VHP) is standard, delivering an additional 3.73 kW (5 hp) in forward gears 1-4 and reverse gears 1-3. This balances traction, speed and horsepower to optimize rimpull and conserves fuel. VHP...

Open the catalog to page 6

Power Train Maximum power to the ground We designed the 16M to give you efficiency and longevity in your most demanding applications. • Optional Automatic Differential Lock unlocks the differential during a turn and re-locks when straight for easier operation and improved power train protection. • Full Electronic Clutch Pressure Control (ECPC) system optimizes inching modulation for smooth shifts and directional changes, reducing stress on gears. • Standard Programmable Autoshift simplifies operation by allowing the operator to program the transmission to shift at optimal points to match...

Open the catalog to page 7

Service ease and precise blade control Caterpillar designs motor grader frame and drawbar components to give you performance and durability in heavy duty applications. The one-piece forged steel circle stands up to high stress loads, and a sacrificial wear system helps keep your service time and costs down. The articulation hitch features a large tapered roller bearing to carry loads evenly and smoothly. It is sealed to prevent contamination and a locking pin prevents articulation for safety during service or transport. Blade Angle and Moldboard An aggressive blade angle helps you work more...

Open the catalog to page 8

Hydraulics Advanced machine control State-of-the-art electro-hydraulics gives you advanced machine controls with precise and predictable movements. Load Sensing Hydraulics (PPPC) A proven load-sensing system and advanced Proportional Priority Pressure-Compensating (PPPC) electro-hydraulic valves give you superior implement control and enhanced machine performance. Continuously matching hydraulic flow/ pressure to power demands creates less heat and reduces power consumption. • Consistent, Predictable Movement – PPPC valves have different flow rates for the head and rod ends of the cylinder,...

Open the catalog to page 9

Cat Grade Control Cat Grade Control Cross Slope is a standard, fully integrated, factory installed grade control system that helps your operator more easily maintain desired cross slope by automatically controlling one side of the blade. The system is job-ready from day one, and scalable for the future with AccuGrade™ upgrade kits that provide additional 2D and/or 3D control features. Cat MineStar™ System The optional Cat MineStar System is the industry’s broadest suite of integrated mine operations and mobile equipment management technologies, configurable to suit your operation’s needs. •...

Open the catalog to page 10

Integrated Technologies Solutions to make work easier and more efficient Cat Product Link™* Remote monitoring with Product Link improves your overall fleet management effectiveness. Events, diagnostic codes and data like hours, fuel, idle time are transmitted to a secure web based application, VisionLink™. VisionLink includes powerful tools to convey information to you and your Cat dealers, including mapping, working and idle time, fuel level and more. *Product Link licensing not available in all areas. Please consult your Cat dealer for availability.

Open the catalog to page 11All Caterpillar Global Mining catalogs and technical brochures

-

D9 DOZER

20 Pages

-

745

28 Pages

-

725C2

28 Pages

-

Cat ® 621K

4 Pages

-

D9T

20 Pages

-

D8T

20 Pages

-

735B Articulated Truck

20 Pages

-

725 Articulated Truck

20 Pages

-

777D

28 Pages

-

775G

32 Pages

-

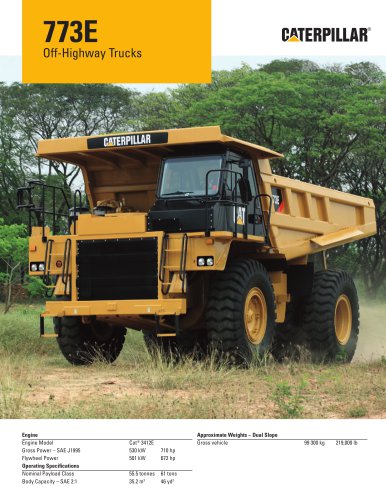

773E

24 Pages

-

772G

28 Pages

-

772

32 Pages

-

770

32 Pages

-

16M

24 Pages

-

14M

28 Pages

-

795F AC

24 Pages

-

793D

32 Pages

-

789D

28 Pages

-

789C

28 Pages

-

HW300

16 Pages

-

785D

24 Pages

-

AEXQ1170 ShovelsBrochure

32 Pages

-

D11T/D11T CD

28 Pages

-

D10T

20 Pages

-

MD6240 Rotary Drill

28 Pages

-

Cat ® Rock Flow System

2 Pages

-

LHD Vehicles Product Line

8 Pages

-

Mining Truck (797F)

28 Pages

-

Off-Highway Truck (773G)

32 Pages

-

Off-Highway Truck (777G)

36 Pages

-

Open Bowl Scraper (627G)

24 Pages

-

Open Bowl Scraper (627H)

20 Pages

-

Open Bowl Scraper (623H)

20 Pages

-

Open Bowl Scraper (631G)

24 Pages

-

Open Bowl Scraper (621H)

20 Pages

-

Open Bowl Scraper (657G)

24 Pages

-

Longwall Mining Equipment

12 Pages

-

LHD Vehicles

8 Pages

-

CTS Drive Systems

8 Pages

-

Cat® Trucks: The ONE for Mining

28 Pages

-

Belt Systems - Underground

12 Pages

-

Armored Face Conveyors (AFCs)

12 Pages

-

Longwall Automation

12 Pages

-

Cat® track drills MD5150

28 Pages

-

Electric Rope Shovels 7182

3 Pages

-

Cat® track drills MD5125

4 Pages

-

Cat® track drills MD5050 T

4 Pages

-

Cat® track drills MD5090

4 Pages

-

Cat® track drills MD5075

4 Pages

-

Electric Rope Shovels 7295

3 Pages

-

Electric Rope Shovels 7395

3 Pages

-

Cat® track drills MD5050

4 Pages

-

Cat® Rotary drills MD6750

4 Pages

-

Cat® Rotary drills MD6640

4 Pages

-

Electric Rope Shovels 7495

3 Pages

-

Cat® 8750 DRAGLINE RANGE

28 Pages

-

Master Idler

399 Pages

-

Cat® 8200 DRAGLINE RANGE

2 Pages

-

Cat® 8200-127 Dragline

2 Pages

-

Cat® 8200-126 Dragline

2 Pages

-

Cat® 8200-125 Dragline

2 Pages

-

Cat® 8200-124 Dragline

2 Pages

-

Cat® 8200-123 Dragline

2 Pages

-

Cat® 8200-113 Dragline

2 Pages

-

740B EJ articulated track

24 Pages

-

740B articulated track

20 Pages

-

730 ejector articulated track

20 Pages

-

730 articulated track

20 Pages

-

Feeder Breakers

4 Pages

-

Belt Systems & Belt Products

8 Pages

Archived catalogs

-

Draglines

8 Pages

-

988H Wheel Loader

24 Pages

-

844H Wheel Dozer

20 Pages

-

Scoops

8 Pages

-

Face Haulers

12 Pages

-

Continuous Miners

8 Pages

-

Longwall Shearers

16 Pages

-

Roof Support Carriers

12 Pages

-

Roof Support Systems

8 Pages

-

Automated Plow Systems

12 Pages

-

Jumbo Drills

12 Pages

-

Rotary Blasthole Drills

8 Pages

-

Hydraulic Track Drills

8 Pages

-

Hydraulic Shovels

12 Pages

-

Highwall Mining System

8 Pages

-

Electric Rope Shovels

12 Pages

-

Surface Belt Structure

8 Pages