Catalog excerpts

Basic Specifications Hole Depth Single-pass (12 m/39 ft mast) Up to 12.80 m (42 ft)/Multi-pass Up to 55.47 m (182 ft) Hole Depth Single-pass (15 m/49ft mast) Up to 15.85 m (52ft)/Multi-pass Up to 31.08 m (102 ft) Engine Cat® C27 Tier 2 597 kW (800 hp) at 2,100 rpm

Open the catalog to page 1

MD6240 Features: Solid Structures A strong foundation for continuous drilling in harsh conditions, MD6240 is designed for long life with features such as a mast with double cut lacing, integral A-frame design, and a solid mainframe with low deflection rates in stress areas. Power Group Fast cycle times are achieved through top of class bit load, rotary head horsepower, bailing air and a multitude of time-saving systems for maximum efficiency. Carousel Pipe Rack Rapid pipe changes that are safe, efficient and completely controlled from inside of operator’s cab. A hydraulic break out wrench...

Open the catalog to page 2

Proven Performer Low-cost of ownership, highly productive and long lasting High productivity and low cost of ownership is yours with the MD6240 Rotary Drill. With bit load force of 24 000 kg (52,911 lb) and the capability to drill depths up to 55.47 m (182 ft) the MD6240 is well equipped to drill in hard or soft rock applications. Built to be reliable, safe and easy to service for years to come. 3

Open the catalog to page 3

Solid Structures To withstand your harsh quarry and mining environments

Open the catalog to page 4

Best built for long life, the MD6240 has heavy-duty structures. The mast, integral A-frame, and mainframe are durable providing a strong platform needed for drilling in harsh conditions. The MD6240 is equipped to perform in challenging environments and provides high availability, positively impacting your bottom line. All welded structures are made in house and they comply with AWS 14.3 welding standard. The welded structures are inspected after the manufacturing process providing reliable, maintenance free and long lasting platform for the drill. Sturdy Mast • The mast is made of...

Open the catalog to page 5

Power Group High on efficiency; low on cost To achieve low cost, high efficiency drilling, your power group configuration is selected to match the needs of your specific geology and site conditions. We have numerous configurations for low pressure rotary drilling or high pressure DTH hammer drilling. Power groups are arranged in-line for easy access, from both sides, to the engine, compressor, hydraulic pumps, plumbing and other components, which translates into safer serviceability and lower maintenance cost. Engines To match your application demands, MD6240 has three choices for engine...

Open the catalog to page 6

Hydraulic System For efficient flushing of cuttings and dust out of the bore hole, the air compressor delivers the right amount of bailing air based on hole diameter, depth and material density. Air-on-demand control system regulates air intake to match the amount of compressed air being used. For ample capability, our cooler systems are designed to assure unrestricted airflow and reduce excessive operating heat, which extends life of engine, compressor, and hydraulic components. • Rated up to 52° C (125° F) ambient cooling capacity • Split or single cooler • Side by side engine radiator •...

Open the catalog to page 7

Mast System Strong and sturdy To assure long life, all mast structures are designed with double-cut lacing in high stress areas. There are several application-specific masts to choose from. Mast Height Pipe Length Single Pass Depth Pipe Diameter Pipe Wall Thickness Rotary Drill Head (1) A single, double-acting cylinder, cable pull-down system produces 22 680 kg (50,000 lb) of pull-down force and 22 680 kg (50,000 lb) of hoist force. The cylinder rod is fixed on both ends with a moving barrel, providing high efficiency and reducing feed system wear and maintenance. • One variable...

Open the catalog to page 8

Angle Drilling The MD6420 can drill in angles up to 25 degrees (in 5 degree increments). Dual mast locks are located under the deck and hydraulically operated dust curtains are available for angle drilling. Pipe Rack Carousel (2) The hydraulically operated carousel-type pipe changer is located outside of the mast structure, and all functions are controlled from a console in operator’s cab, which assures efficient and safe drill string changes and storage. The carousel provides automatic indexing of drill pipes in relation to the rotary head. • Pipe diameter 114-178 mm (4.5-7.0 in) • 12 m...

Open the catalog to page 9

Dust Collection Largest chamber in the industry For efficient dust collection MD6240 has a dust collector rated at 127 m3/min (4,500 ft3/min) and separate water injection system. Both dry and water injection systems can be mounted on the same drill. • Water injection system options: – Three tanks totaling 1271 L (336 gal) mounted under the front deck or – One tank 1514 L (400 gal) mounted on top-deck (mounted in place of Dry Dust Collector) Dust Curtain With the largest dust chamber in the industry, the MD6240 has a total enclosed area of 4.2 m2 (45.14 ft2) and is surrounded by heavy rubber...

Open the catalog to page 10

Fully Equipped Cab For operator safety and comfort Safe and Effortless Operation To limit operator fatigue the MD6240 controls are ergonomic. The FOPS certified cab has tinted safety glass windows and a closed circuit camera system for 360° visibility. Two heavy-duty doors provide quick egress to the drill table or the main deck. Additional Safety Features • 45° control console, in relation to deck, assures good overview of drill table • Closed-circuit camera system • Two heavy-duty swing doors for convenient cab access • Low sound and vibration levels • Emergency ingress/egress • Multiple...

Open the catalog to page 11

Serviceability and Customer Support Easy and safe to access all service points Large Main Deck The MD6240 large deck (front and rear) plus wide walkways assure a safe operating area and more efficient maintenance. Access to walkways are on both sides of drill for quick access to all major components for daily pre-start checks, preventive maintenance and adjustments. The stationary drill table/rear deck (mast/cab area) provides access to the mast area and to the main deck during all drilling modes, including angle drilling. Immediate access to the power group including the engine,...

Open the catalog to page 12All Caterpillar Global Mining catalogs and technical brochures

-

D9 DOZER

20 Pages

-

745

28 Pages

-

725C2

28 Pages

-

Cat ® 621K

4 Pages

-

D9T

20 Pages

-

D8T

20 Pages

-

735B Articulated Truck

20 Pages

-

725 Articulated Truck

20 Pages

-

777D

28 Pages

-

775G

32 Pages

-

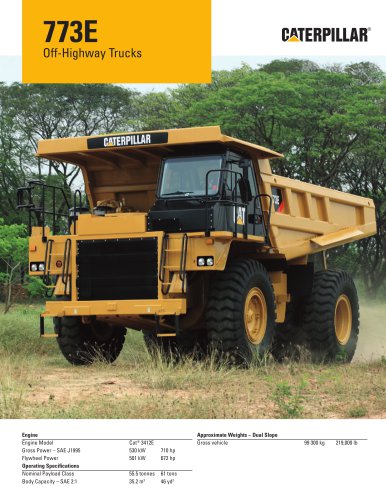

773E

24 Pages

-

772G

28 Pages

-

772

32 Pages

-

770

32 Pages

-

16M

24 Pages

-

14M

28 Pages

-

795F AC

24 Pages

-

793D

32 Pages

-

789D

28 Pages

-

789C

28 Pages

-

HW300

16 Pages

-

785D

24 Pages

-

AEXQ1170 ShovelsBrochure

32 Pages

-

D11T/D11T CD

28 Pages

-

D10T

20 Pages

-

Cat ® Rock Flow System

2 Pages

-

LHD Vehicles Product Line

8 Pages

-

Mining Truck (797F)

28 Pages

-

Motor Grader (16M)

24 Pages

-

Off-Highway Truck (773G)

32 Pages

-

Off-Highway Truck (777G)

36 Pages

-

Open Bowl Scraper (627G)

24 Pages

-

Open Bowl Scraper (627H)

20 Pages

-

Open Bowl Scraper (623H)

20 Pages

-

Open Bowl Scraper (631G)

24 Pages

-

Open Bowl Scraper (621H)

20 Pages

-

Open Bowl Scraper (657G)

24 Pages

-

Longwall Mining Equipment

12 Pages

-

LHD Vehicles

8 Pages

-

CTS Drive Systems

8 Pages

-

Cat® Trucks: The ONE for Mining

28 Pages

-

Belt Systems - Underground

12 Pages

-

Armored Face Conveyors (AFCs)

12 Pages

-

Longwall Automation

12 Pages

-

Cat® track drills MD5150

28 Pages

-

Electric Rope Shovels 7182

3 Pages

-

Cat® track drills MD5125

4 Pages

-

Cat® track drills MD5050 T

4 Pages

-

Cat® track drills MD5090

4 Pages

-

Cat® track drills MD5075

4 Pages

-

Electric Rope Shovels 7295

3 Pages

-

Electric Rope Shovels 7395

3 Pages

-

Cat® track drills MD5050

4 Pages

-

Cat® Rotary drills MD6750

4 Pages

-

Cat® Rotary drills MD6640

4 Pages

-

Electric Rope Shovels 7495

3 Pages

-

Cat® 8750 DRAGLINE RANGE

28 Pages

-

Master Idler

399 Pages

-

Cat® 8200 DRAGLINE RANGE

2 Pages

-

Cat® 8200-127 Dragline

2 Pages

-

Cat® 8200-126 Dragline

2 Pages

-

Cat® 8200-125 Dragline

2 Pages

-

Cat® 8200-124 Dragline

2 Pages

-

Cat® 8200-123 Dragline

2 Pages

-

Cat® 8200-113 Dragline

2 Pages

-

740B EJ articulated track

24 Pages

-

740B articulated track

20 Pages

-

730 ejector articulated track

20 Pages

-

730 articulated track

20 Pages

-

Feeder Breakers

4 Pages

-

Belt Systems & Belt Products

8 Pages

Archived catalogs

-

Draglines

8 Pages

-

988H Wheel Loader

24 Pages

-

844H Wheel Dozer

20 Pages

-

Scoops

8 Pages

-

Face Haulers

12 Pages

-

Continuous Miners

8 Pages

-

Longwall Shearers

16 Pages

-

Roof Support Carriers

12 Pages

-

Roof Support Systems

8 Pages

-

Automated Plow Systems

12 Pages

-

Jumbo Drills

12 Pages

-

Rotary Blasthole Drills

8 Pages

-

Hydraulic Track Drills

8 Pages

-

Hydraulic Shovels

12 Pages

-

Highwall Mining System

8 Pages

-

Electric Rope Shovels

12 Pages

-

Surface Belt Structure

8 Pages