Catalog excerpts

Longwall Automation

Open the catalog to page 1

Unparalleled Control Excellent automation is the basis for the success of a longwall – the quality and reliability of the automation system are key factors in the success of the operation. Caterpillar is the only manufacturer that is able to provide a complete modular family of powerful controllers that integrate fully with Cat® longwall equipment. This means one-stop shopping, no interfacing problems and products customized to your needs. Full Range, Full Integration Design Criteria Based on the successful Cat PM4 series, the PMC™ family is a new generation of controllers designed to meet...

Open the catalog to page 2

Benefits The integration of the various machines (plow or shearer, AFC, and roof supports) allows optimal tuning of the complete system. This results in numerous benefits for the user, including: •• Full utilization of plow, shearer and AFC capacity •• Protection of the system from overload •• Minimized chain downtime, extended service life of drives •• ptimization of chain tension, dependent on load, O for all load conditions •• Maximum possible startup torque for heavy-load start •• achine speed adjusted to the conveyor load, no M overload of system Roof supports •• Timely movement of...

Open the catalog to page 3

The communication within the PMC™ family is based on a field bus system The PMC™ Family A Controller for Every Need The PMC™ system offers a tailored control unit for each of the various longwall functions: •• PMC™-R for roof support systems •• PMC™-D as drive control •• MC™-V for visualization and parameter setup of the P drive system •• PMC™-P node computer to act as interface between the Cat controller network, third-party systems and the mine computer. The module implements data transmission to the surface via optical fiber, modem or copper wire. •• CU for visualization and control of...

Open the catalog to page 4

Modularity Because PMC™ controllers are modular, each tailored control is located next to the device it is controlling. This minimizes data transfer problems and simplifies troubleshooting. Rigorous Testing All components are designed and manufactured in accordance with the latest standards and are subject to strict quality control. Circuit boards use the latest surfacemount technology and are secured in special trays to provide superior protection against shock and vibration. Rigorous quality control testing such as function control, vibration and pressure testing ensures the highest...

Open the catalog to page 5

PMC™-R Intelligence for Roof Supports 1 Visualization and Control Unit (VCU) at the surface 2 VCU underground 3 Data transmission underground to surface Control Unit 4 Data transmission Shield Control Unit to server PMC™-R 5 Server PMC™-R 6 Shield Control Unit (SCU) PMC™-R 7 Power supply 8 Power adapter integrated into power supply 9 Isolation adapter The PMC™-R system is the next-generation, state-ofthe-art Cat automated control for longwall roof support applications. Based on the PM4, it combines the best features of that system with additional features operators wanted. The result is an...

Open the catalog to page 6

Custom Keys The 30-key keypad allows a large number of additional special functions to be assigned to membrane keys, eliminating access problems for customer-specific software functions. On the standard version of the PMC™-R system information is viewed via a 2-line, LCD display which is easy to read from different angles. The information default display shows the main face data, such as leg pressure, ram cylinder stroke, shield number or shearer/ plow position. Error messages are displayed, if any occur. The LCD display can also display Cyrillic and Chinese characters. PMC™-R Roof Support...

Open the catalog to page 7

PMC™-D Dedicated Drive Control In combination with Cat Controlled Start Transmission (CST) drives, the PMC™-D controller offers control of AFC drives with unparalleled integration of overall system control. Typically dedicated to a gearbox or drive and mounted close to it, the PMC™-D contains all the necessary hardware and tried-and-tested CST control algorithms to control a drive system effectively. The drive control software is based on that used in other members of the PMC™ family. PMC™-D - used for measurement and control tasks Connected to a junction box in the CST gearbox, the PMC™-D...

Open the catalog to page 8

Controlled Start Transmission Cat CST drives with PMC™-D control unit offer high power with safe startup of the face conveyor, full utilization of installed power, long service life and compact dimensions. Cat CST drives offer: •• ntelligent compact drive for longwall conveyors I with up to 1 200 kW (1,930 hp) drive power •• aximum short-duration output torque (3 sec) of M 650 000 Nm •• lutch delivers maximum efficiency with minimum C operational slip •• Minimal energy loss and heat dissipation •• ery precise speed and torque control using V a high-dynamic clutch •• reely selectable...

Open the catalog to page 9

PMC™-P Brings it All Together The PMC™-P (Provider) is a node computer that provides the interface between individual controllers and equipment and the computer network or third-party systems. It converts protocols to allow data exchange. The PMC™-P also coordinates elements of the longwall. For example, if the shearer is cutting large quantities of coal, it must either speed up the conveyor drives or, if that is not possible, slow down the shearer. It also passes shearer position data to drive controllers so that they can fold in the roof support flipper at the appropriate time to prevent...

Open the catalog to page 10

Main View The main view shows the actual conveyor position versus the targeted position in a multi-color graph. Prop pressure values and advancing stroke values measured are presented as bar charts. Information about the shield status as well as details on position and direction of movement of the mining machine complete the main view. The three-dimensional representation of the longwall is based on the same data as the two-dimensional representation of the master control unit. The VCU and the graphic program can be linked locally or through a network. Zones of high pressure can be...

Open the catalog to page 11All Caterpillar Global Mining catalogs and technical brochures

-

D9 DOZER

20 Pages

-

745

28 Pages

-

725C2

28 Pages

-

Cat ® 621K

4 Pages

-

D9T

20 Pages

-

D8T

20 Pages

-

735B Articulated Truck

20 Pages

-

725 Articulated Truck

20 Pages

-

777D

28 Pages

-

775G

32 Pages

-

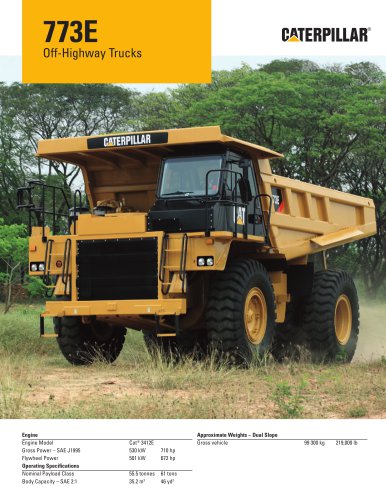

773E

24 Pages

-

772G

28 Pages

-

772

32 Pages

-

770

32 Pages

-

16M

24 Pages

-

14M

28 Pages

-

795F AC

24 Pages

-

793D

32 Pages

-

789D

28 Pages

-

789C

28 Pages

-

HW300

16 Pages

-

785D

24 Pages

-

AEXQ1170 ShovelsBrochure

32 Pages

-

D11T/D11T CD

28 Pages

-

D10T

20 Pages

-

MD6240 Rotary Drill

28 Pages

-

Cat ® Rock Flow System

2 Pages

-

LHD Vehicles Product Line

8 Pages

-

Mining Truck (797F)

28 Pages

-

Motor Grader (16M)

24 Pages

-

Off-Highway Truck (773G)

32 Pages

-

Off-Highway Truck (777G)

36 Pages

-

Open Bowl Scraper (627G)

24 Pages

-

Open Bowl Scraper (627H)

20 Pages

-

Open Bowl Scraper (623H)

20 Pages

-

Open Bowl Scraper (631G)

24 Pages

-

Open Bowl Scraper (621H)

20 Pages

-

Open Bowl Scraper (657G)

24 Pages

-

Longwall Mining Equipment

12 Pages

-

LHD Vehicles

8 Pages

-

CTS Drive Systems

8 Pages

-

Cat® Trucks: The ONE for Mining

28 Pages

-

Belt Systems - Underground

12 Pages

-

Armored Face Conveyors (AFCs)

12 Pages

-

Cat® track drills MD5150

28 Pages

-

Electric Rope Shovels 7182

3 Pages

-

Cat® track drills MD5125

4 Pages

-

Cat® track drills MD5050 T

4 Pages

-

Cat® track drills MD5090

4 Pages

-

Cat® track drills MD5075

4 Pages

-

Electric Rope Shovels 7295

3 Pages

-

Electric Rope Shovels 7395

3 Pages

-

Cat® track drills MD5050

4 Pages

-

Cat® Rotary drills MD6750

4 Pages

-

Cat® Rotary drills MD6640

4 Pages

-

Electric Rope Shovels 7495

3 Pages

-

Cat® 8750 DRAGLINE RANGE

28 Pages

-

Master Idler

399 Pages

-

Cat® 8200 DRAGLINE RANGE

2 Pages

-

Cat® 8200-127 Dragline

2 Pages

-

Cat® 8200-126 Dragline

2 Pages

-

Cat® 8200-125 Dragline

2 Pages

-

Cat® 8200-124 Dragline

2 Pages

-

Cat® 8200-123 Dragline

2 Pages

-

Cat® 8200-113 Dragline

2 Pages

-

740B EJ articulated track

24 Pages

-

740B articulated track

20 Pages

-

730 ejector articulated track

20 Pages

-

730 articulated track

20 Pages

-

Feeder Breakers

4 Pages

-

Belt Systems & Belt Products

8 Pages

Archived catalogs

-

Draglines

8 Pages

-

988H Wheel Loader

24 Pages

-

844H Wheel Dozer

20 Pages

-

Scoops

8 Pages

-

Face Haulers

12 Pages

-

Continuous Miners

8 Pages

-

Longwall Shearers

16 Pages

-

Roof Support Carriers

12 Pages

-

Roof Support Systems

8 Pages

-

Automated Plow Systems

12 Pages

-

Jumbo Drills

12 Pages

-

Rotary Blasthole Drills

8 Pages

-

Hydraulic Track Drills

8 Pages

-

Hydraulic Shovels

12 Pages

-

Highwall Mining System

8 Pages

-

Electric Rope Shovels

12 Pages

-

Surface Belt Structure

8 Pages