Website:

Caterpillar Global Mining

Website:

Caterpillar Global Mining

Group: Caterpillar

Catalog excerpts

Weight (without Cutter Module) Operating Specification Machine Weight 225 000 kg 495,6651b Maximum Penetration Capability 305 m 1,000 ft Mine Mode Dimensions (without Cutter Module)

Open the catalog to page 1

Features Maximum Extraction Low cost coal to traditional mining methods. Safe Operation The entire mining cycle is completed by a three- or four-man crew, with no personnel going underground at any time. Excellent Mobility The highwall miner trams easily from entry to entry and discharges coal in tight spaces. Operator Comfort The air-conditioned cab offers an ergonomic workplace where all controls are within the operator’s reach. Easy Equipment Relocation The highwall mining system can be taken apart in modules – sized for transport using regular public roads.

Open the catalog to page 2

Linking underground and surface mining operations, the Cat® Highwall Mining System is a testament to innovative mining equipment. The HW300 offers a safe and innovative method for extracting coal from exposed seams in a multitude of applications. 3

Open the catalog to page 3

The Highwall Mining Method Extracting coal affordably and safely. Feasibility Determination Our highly skilled experts are eager to assist you to determine the feasibility of your highwall mining project. The Caterpillar team uses an evaluation of your geological data and site plan to determine how best to use a Cat highwall mining system.

Open the catalog to page 4

Highwall mining is a proven primary method for mining coal from exposed seams. In this method of mining, an unmanned cutter module is driven underground and operated in front of the highwall. The highwall mining machine stands on the pit floor or on a bench, directly in front of the exposed seam and makes long parallel rectangular drives into the coal seam. A remote-operated cutter module is pushed into the seam by a string of push beams (unmanned coal-conveying elements) that transport the mined coal back to the entry of the drive onto a stockpile. The whole mining cycle is completed by a...

Open the catalog to page 5

Cutter Module Proven technology for accurate cuts. Proven Cutter Module Caterpillar offers two electric cutter modules: a low-profile cutter module for seams 0.76-1.62 m (2.5-5.3 ft) in height and a mid-seam cutter module to mine 1.3-3.05 m (4.3-10 ft) seams. The cutter modules are interchangeable and quickly attached to the power head assembly. The cutting cycle is fully automated, yet allows the operator to manually adjust the machine function using an ampere reading as the coal seam varies. This proven technology allows the cutter module to accurately follow the coal seam and produce a...

Open the catalog to page 6

Ergonomic design for comfort, control and productivity. Operator Comfort The Cat highwall mining system is equipped with a comfortable, climate controlled, pressurized cab that offers a full view of the mining operation and the highwall. The full suspension operator seat and the two user-friendly touchscreens create an ergonomic workplace, placing controls and system information at the operator’s fingertips. Improved maneuverability in tight spaces. Excellent Mobility The Cat highwall mining system is an agile, self-propelled machine that operates on contour benches as narrow as 18 m (59...

Open the catalog to page 7

Push Beams The backbone of the highwall mining system. Dependable Push Beams Cat push beams are 6 m (20 ft) long, rectangular, reinforced steel box structures joined together to form a string, which connects the highwall mining system to the cutter module. The push beam string is the backbone of the machine; pushing and pulling the cutter module in and out of the coal seam. The push beam conveys mined coal inside. The enclosed beam protects the coal from contamination and supports the hose chain that supplies control and power to the cutter module. Other Cat push beam advantages include: •...

Open the catalog to page 8

Reel and Chain Storage and protection of cables and hoses. Robust Reel and Chain A steel-armored hose chain stores and protects all electric power cables, hydraulic and coolant lines, and the control cable to the cutter module. The hose chain is automatically unrolled and retracted on a reel during mining. Control System Keeping the operation productive. Control System with Diagnostics The Cat highwall mining system’s operation is controlled by a Programmable Logic Controller, which provides reliable performance for greater uptime. A comprehensive diagnostics system, including...

Open the catalog to page 9

Equipment Relocation Convenient modularity for quick assembly. Easy Machine Relocation Anchoring System Maximum Stabilization even under toughest conditions. Anchoring System Two drills mounted on the front of the machine are used to drill into the pit floor up to 2.4 m (8 ft). High-strength pins are then inserted through the base frame into the pit floor to help stabilize the machine and to maintain its accurate position, even under tough pushing and pulling conditions. For quick relocation over long distances, the Cat highwall mining system can be taken apart in modules. Rapid disassembly...

Open the catalog to page 10

Support Services to keep your equipment productive. Product Support Every HW300 is backed by 24/7 support from highly skilled and experienced staff. Large warehouse stocks with spare parts ensure the highest levels of machine uptime, and service and parts back-up can be tailored to your needs. Safety Designed with safety as the first priority. Caterpillar can arrange operational and technical training which covers every aspect of the HW300 Highwall Miner. A two-week training program from the Caterpillar facility in Beckley, West Virginia, USA, is offered to new customers and to existing...

Open the catalog to page 11

HW300 Highwall Mining System Specifications Environmental and Operational Conditions The Cat HW300 is designed for following environmental and operating conditions: Mine Application Trench Application Open Pit Mining Contour Mining Ambient Temperature –30° C to +35° C (–22° F to 95° F) Arctic and Tropical Packages are optional Pit Floor Gradient 8 degrees nominal in any direction, 10 degrees maximum in any direction for traveling Maximum Seam Gradient 8 degrees down dip relative to horizontal (Level side-to-side, pit floor prepared at 3 degrees) Water Consumption Electric Power (Installed)...

Open the catalog to page 12All Caterpillar Global Mining catalogs and technical brochures

-

D9 DOZER

20 Pages

-

745

28 Pages

-

725C2

28 Pages

-

Cat ® 621K

4 Pages

-

D9T

20 Pages

-

D8T

20 Pages

-

735B Articulated Truck

20 Pages

-

725 Articulated Truck

20 Pages

-

777D

28 Pages

-

775G

32 Pages

-

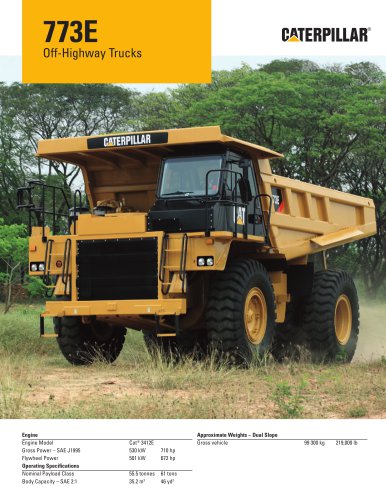

773E

24 Pages

-

772G

28 Pages

-

772

32 Pages

-

770

32 Pages

-

16M

24 Pages

-

14M

28 Pages

-

795F AC

24 Pages

-

793D

32 Pages

-

789D

28 Pages

-

789C

28 Pages

-

785D

24 Pages

-

AEXQ1170 ShovelsBrochure

32 Pages

-

D11T/D11T CD

28 Pages

-

D10T

20 Pages

-

MD6240 Rotary Drill

28 Pages

-

Cat ® Rock Flow System

2 Pages

-

LHD Vehicles Product Line

8 Pages

-

Mining Truck (797F)

28 Pages

-

Motor Grader (16M)

24 Pages

-

Off-Highway Truck (773G)

32 Pages

-

Off-Highway Truck (777G)

36 Pages

-

Open Bowl Scraper (627G)

24 Pages

-

Open Bowl Scraper (627H)

20 Pages

-

Open Bowl Scraper (623H)

20 Pages

-

Open Bowl Scraper (631G)

24 Pages

-

Open Bowl Scraper (621H)

20 Pages

-

Open Bowl Scraper (657G)

24 Pages

-

Longwall Mining Equipment

12 Pages

-

LHD Vehicles

8 Pages

-

CTS Drive Systems

8 Pages

-

Cat® Trucks: The ONE for Mining

28 Pages

-

Belt Systems - Underground

12 Pages

-

Armored Face Conveyors (AFCs)

12 Pages

-

Longwall Automation

12 Pages

-

Cat® track drills MD5150

28 Pages

-

Electric Rope Shovels 7182

3 Pages

-

Cat® track drills MD5125

4 Pages

-

Cat® track drills MD5050 T

4 Pages

-

Cat® track drills MD5090

4 Pages

-

Cat® track drills MD5075

4 Pages

-

Electric Rope Shovels 7295

3 Pages

-

Electric Rope Shovels 7395

3 Pages

-

Cat® track drills MD5050

4 Pages

-

Cat® Rotary drills MD6750

4 Pages

-

Cat® Rotary drills MD6640

4 Pages

-

Electric Rope Shovels 7495

3 Pages

-

Cat® 8750 DRAGLINE RANGE

28 Pages

-

Master Idler

399 Pages

-

Cat® 8200 DRAGLINE RANGE

2 Pages

-

Cat® 8200-127 Dragline

2 Pages

-

Cat® 8200-126 Dragline

2 Pages

-

Cat® 8200-125 Dragline

2 Pages

-

Cat® 8200-124 Dragline

2 Pages

-

Cat® 8200-123 Dragline

2 Pages

-

Cat® 8200-113 Dragline

2 Pages

-

740B EJ articulated track

24 Pages

-

740B articulated track

20 Pages

-

730 ejector articulated track

20 Pages

-

730 articulated track

20 Pages

-

Feeder Breakers

4 Pages

-

Belt Systems & Belt Products

8 Pages

Archived catalogs

-

Draglines

8 Pages

-

988H Wheel Loader

24 Pages

-

844H Wheel Dozer

20 Pages

-

Scoops

8 Pages

-

Face Haulers

12 Pages

-

Continuous Miners

8 Pages

-

Longwall Shearers

16 Pages

-

Roof Support Carriers

12 Pages

-

Roof Support Systems

8 Pages

-

Automated Plow Systems

12 Pages

-

Jumbo Drills

12 Pages

-

Rotary Blasthole Drills

8 Pages

-

Hydraulic Track Drills

8 Pages

-

Hydraulic Shovels

12 Pages

-

Highwall Mining System

8 Pages

-

Electric Rope Shovels

12 Pages

-

Surface Belt Structure

8 Pages