Website:

Caterpillar Global Mining

Website:

Caterpillar Global Mining

Group: Caterpillar

Catalog excerpts

Intelligent CST Drive System

Open the catalog to page 1

The Drive for Productivity With constant pressure for greater productivity, improving the performance of longwall systems remains a key goal for mine operators. At Caterpillar, all aspects of longwall operation and machinery are continuously reviewed to find ways to improve productivity and reduce the overall cost of mining. The performance of the face conveyor system is continually improving. Improved Performance Ever more powerful systems require ever more horsepower, heavier chains and faster conveyor speed with maximum availability. What was needed was a truly intelligent drive system...

Open the catalog to page 2

The CST is a closed system. A water hose for the heat exchanger and the 37-wire cable for the drive control unit and communication are the only external connections. A fast, real-time ope ating drive con rol unit r t controls all operations in the CST drive system via the integral servovalve. Each gear ox is equipp b ed with a control unit interconnected via control cables. These units can communicate with minespecific face control systems underground or on the surface. The tried and tested Cat® hydraulic chain tensioner is used for safe operation during chain maintenance work. Startup...

Open the catalog to page 3

Overload Protection If the chain is jammed by large pieces of rock or trapped iron, the CST clutch is opened rapidly and the motor is switched off. To achieve this, the output speed is constantly monitored. Within milliseconds, the rotating mass of the gearbox – and particularly of the asynchronous motor – is disconnected from the conveyor chain sprocket. Communication between the drive control units allows all clutches to be opened simultaneously. Benefits •• Instant, effective overload protection:• Excessive chain forces and the risk of instant chain failures are virtually eliminated....

Open the catalog to page 4

V-Drive Visualization Software This software visualizes all CST, tail drive and chain tensioning data. It allows changes to drive system parameters and monitors load-sharing, conveyor speed, clutch sensors etc. The software also stores all CST data and undertakes analysis and trending of sensor values. It allows export of data to office applica ions such as t electronic spread heets. Chinese, German and Russian s versions of the software are also available. Field Experience Visualization of CST data by V-Drive The CST drive system was applied for the first time in 1995 on a high...

Open the catalog to page 5

ICDS – Integrated CST Drive System The ICDS is the result of continuing cooperation between Caterpillar and Baldor Electric Company. It combines the tried-and-tested CST drive system for face conveyors with a newly developed special Baldor Electric motor with our new PMC™-D drive control system. The ICDS has a special asynchronous motor from Baldor Electric Company, with rated power of currently up to 1 200 kW (1,950 hp). The nominal motor running torque is 7 640 Nm (5,635 lb-ft) at full nominal speed. The maximum AFC starting torque (breakdown torque) is 3 x 19 100 Nm (14,090 lb-ft). Space...

Open the catalog to page 6

Technical Data Application Maximum output torque for a short duration (3 sec.) Maximum input speed (motor speed) Maximum installed power* at: Chain type longwall machinery like face conveyors 300 000 Nm - in-line drive system - right/left-angle drive system - in-line drive system - right/left-angle drive system Dimensions In-line gearbox (P version) - height - length (without drive connection) - width Dimensions Right-/left-angle gearbox (KP version) - height - length (without drive connection) - width Size comparison between CST30, CST45 and CST65

Open the catalog to page 7

Intelligent CST Drive System For more complete information on Cat products, dealer services, and industry solutions, visit us on the web at mining.cat.com and www.cat.com © 2011 Caterpillar Inc. All rights reserved Materials and specifications are subject to change without notice. Featured machines in photos may include additional equipment. See your Cat dealer for available options. CAT, CATERPILLAR, their respective logos, “Caterpillar Yellow” and the “Power Edge” trade dress, as well as corporate and product identity used herein, are trademarks of Caterpillar and may not be used without...

Open the catalog to page 8All Caterpillar Global Mining catalogs and technical brochures

-

D9 DOZER

20 Pages

-

745

28 Pages

-

725C2

28 Pages

-

Cat ® 621K

4 Pages

-

D9T

20 Pages

-

D8T

20 Pages

-

735B Articulated Truck

20 Pages

-

725 Articulated Truck

20 Pages

-

777D

28 Pages

-

775G

32 Pages

-

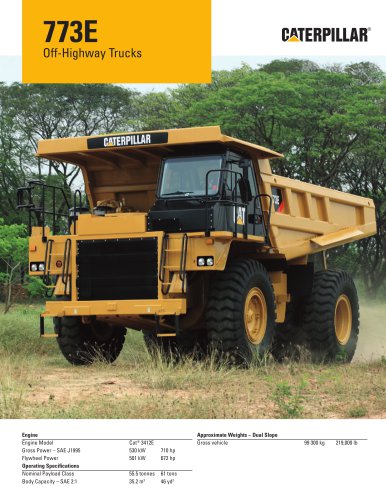

773E

24 Pages

-

772G

28 Pages

-

772

32 Pages

-

770

32 Pages

-

16M

24 Pages

-

14M

28 Pages

-

795F AC

24 Pages

-

793D

32 Pages

-

789D

28 Pages

-

789C

28 Pages

-

HW300

16 Pages

-

785D

24 Pages

-

AEXQ1170 ShovelsBrochure

32 Pages

-

D11T/D11T CD

28 Pages

-

D10T

20 Pages

-

MD6240 Rotary Drill

28 Pages

-

Cat ® Rock Flow System

2 Pages

-

LHD Vehicles Product Line

8 Pages

-

Mining Truck (797F)

28 Pages

-

Motor Grader (16M)

24 Pages

-

Off-Highway Truck (773G)

32 Pages

-

Off-Highway Truck (777G)

36 Pages

-

Open Bowl Scraper (627G)

24 Pages

-

Open Bowl Scraper (627H)

20 Pages

-

Open Bowl Scraper (623H)

20 Pages

-

Open Bowl Scraper (631G)

24 Pages

-

Open Bowl Scraper (621H)

20 Pages

-

Open Bowl Scraper (657G)

24 Pages

-

Longwall Mining Equipment

12 Pages

-

LHD Vehicles

8 Pages

-

Cat® Trucks: The ONE for Mining

28 Pages

-

Belt Systems - Underground

12 Pages

-

Armored Face Conveyors (AFCs)

12 Pages

-

Longwall Automation

12 Pages

-

Cat® track drills MD5150

28 Pages

-

Electric Rope Shovels 7182

3 Pages

-

Cat® track drills MD5125

4 Pages

-

Cat® track drills MD5050 T

4 Pages

-

Cat® track drills MD5090

4 Pages

-

Cat® track drills MD5075

4 Pages

-

Electric Rope Shovels 7295

3 Pages

-

Electric Rope Shovels 7395

3 Pages

-

Cat® track drills MD5050

4 Pages

-

Cat® Rotary drills MD6750

4 Pages

-

Cat® Rotary drills MD6640

4 Pages

-

Electric Rope Shovels 7495

3 Pages

-

Cat® 8750 DRAGLINE RANGE

28 Pages

-

Master Idler

399 Pages

-

Cat® 8200 DRAGLINE RANGE

2 Pages

-

Cat® 8200-127 Dragline

2 Pages

-

Cat® 8200-126 Dragline

2 Pages

-

Cat® 8200-125 Dragline

2 Pages

-

Cat® 8200-124 Dragline

2 Pages

-

Cat® 8200-123 Dragline

2 Pages

-

Cat® 8200-113 Dragline

2 Pages

-

740B EJ articulated track

24 Pages

-

740B articulated track

20 Pages

-

730 ejector articulated track

20 Pages

-

730 articulated track

20 Pages

-

Feeder Breakers

4 Pages

-

Belt Systems & Belt Products

8 Pages

Archived catalogs

-

Draglines

8 Pages

-

988H Wheel Loader

24 Pages

-

844H Wheel Dozer

20 Pages

-

Scoops

8 Pages

-

Face Haulers

12 Pages

-

Continuous Miners

8 Pages

-

Longwall Shearers

16 Pages

-

Roof Support Carriers

12 Pages

-

Roof Support Systems

8 Pages

-

Automated Plow Systems

12 Pages

-

Jumbo Drills

12 Pages

-

Rotary Blasthole Drills

8 Pages

-

Hydraulic Track Drills

8 Pages

-

Hydraulic Shovels

12 Pages

-

Highwall Mining System

8 Pages

-

Electric Rope Shovels

12 Pages

-

Surface Belt Structure

8 Pages