Catalog excerpts

CAT LARGE MOTOR GRADERS ®

Open the catalog to page 1

No. 9 Auto Patrol — 1931 No. 11 — 1934 Diesel No. 12 — 1938 Efficiency. Productivity. Cost per ton. While these terms may not have been familiar to those who invented the first motor grader in the early 1900s, this revolutionary piece of earthmoving equipment certainly had an effect on them. Replacing a horse-drawn implement with a self-propelled model improved earthmoving by leaps and bounds. And when Caterpillar entered the marketplace in 1928, innovations and new product introductions quickly put Caterpillar in a leadership position. Motor grader development is credited to the Russell...

Open the catalog to page 2

New Cat® products and innovations continued with: • Tandem tires, introduced in 1933, and Cat diesel engines, introduced in 1934. • The Diesel No.12, a line introduced in 1938 that still exists today. • The No.16, which was the largest of its kind when it was introduced in 1963, weighing in at 21 092 kilograms (46,500 pounds). • The six-model G Series, which brought the advantages of an articulated frame to the motor grader market when it was introduced in 1973. • The H Series, launched in 1995, which offered the first all-wheel drive machines in the 143H and 163H. • The largest Cat motor...

Open the catalog to page 3

The 24M motor grader is designed to meet the specialized requirements of large mining operations, particularly those maintaining haul roads for trucks with capacities of 172 tonnes (190 tons) or more. Easy serviceability is a key feature in the M Series, with grouped service points for reduced maintenance time, ground level service access wherever possible, and a bolton rear axle to provide easy access to components. Extended service intervals, automatic lubrication, and fast fill and drain capabilities for fluids also contribute to easier maintenance.

Open the catalog to page 4

performance Our mining customers measure profitability by the ore they produce — and the more costeffectively they do that, the more successful they are. There are dozens of variables that impact operations, and mines continually look for ways to improve productivity and reduce costs to improve their bottom line. While drills, draglines, loaders and haul trucks are responsible for producing ore, motor graders have a direct impact on how productively these machines can operate — in particular in their role in haul road maintenance. Motor graders help create and maintain constant grade and...

Open the catalog to page 5

1. round-level service points G make maintenance easier and safer for technicians. 2. he forward view made possible T by a unique raised cab design and one-piece front window improves operator visibility. 3. n engine shutoff switch is A located at ground level to allow anyone nearby to shut it down in case of an emergency. 4. rouped filter locations are G standard to minimize movement around the machine. 5. urable steel tandem walkways D cover both wheels to create a more stable surface. 6. etect, a capability set of Cat® D MineStar™ System, includes a number of sensing and reporting...

Open the catalog to page 6

Our customers consider the safety of their workers a top priority. And we’re doing our best to help them meet their safety goals. Caterpillar considers the safety of everyone in, on or around Cat equipment when we build new products or develop enhanced safety features for existing products. Cat motor graders are designed with protection in mind. We’ve installed grab irons, handrails and steel tandem walkways to help make access and egress safer. Integrated safety features like an operator presence system, hydraulic lockout, ground level engine shut-off and backup alarm enhance safety for...

Open the catalog to page 7

operators When our customers asked us to make our motor graders simpler to learn and easier to operate, we responded with the biggest development in motor grader design in the last 50 years. Our revolutionary cab makes the Cat motor grader the most operator friendly machine of its kind. One of the most significant changes is in the control system. Joysticks replace the traditional levers to deliver precise control and unmatched ease of operation. This revolutionary feature integrates the steering functions into two electro-hydraulic joystick controls. The control pattern is extremely...

Open the catalog to page 8

By polishing the skills of experienced operators and properly training new ones, our customers can maximize the potential of their Cat equipment. Caterpillar operator training programs offer hands-on and simulator training as well as e-learning opportunities for every level of skill.

Open the catalog to page 9

practices Social and environmental responsibility is a way of life at Caterpillar. It’s mandated in our Code of Conduct that we follow sustainable policies and practices in the way we design, engineer and manufacture our products. Our customers, too, make running a safe and environmentally responsible business a top priority. They want engines that burn less (or different) fuel, machines that work more productively and job sites that are more efficient. Some want to repair, rebuild and upgrade their current equipment instead of buying new. And we’re committed to finding solutions that...

Open the catalog to page 10

The 16M motor grader represents a revolution in operational efficiency, visibility, service ease and overall productivity. Designed and manufactured specifically for the 16M, the direct drive countershaft transmission is matched with the powerful Cat C13 engine to maximize power to the ground. A modular rear axle and hydraulic brakes simplify serviceability and reduce operating costs. Conveniently located ecology drains shorten service times and help keep the environment safe by preventing spills. emissions reduction regulations and are poised to take on tomorrow’s challenges as well. We...

Open the catalog to page 11

machines The last decade has seen a revolution in technologies — those that are improving the way mine sites operate and those that will be the foundation for work of the future. Caterpillar is exploring every innovation and leveraging those that are proven to benefit customers by improving safety and sustainability, lowering costs, increasing profitability and boosting efficiency. Productivity solutions like AccuGrade™ and Cat Grade Control increase accuracy, drive efficiency and enhance safety — delivering value to the bottom line. Grade control technologies automatically control the...

Open the catalog to page 12All Caterpillar Global Mining catalogs and technical brochures

-

D9 DOZER

20 Pages

-

745

28 Pages

-

725C2

28 Pages

-

Cat ® 621K

4 Pages

-

D9T

20 Pages

-

D8T

20 Pages

-

735B Articulated Truck

20 Pages

-

725 Articulated Truck

20 Pages

-

777D

28 Pages

-

775G

32 Pages

-

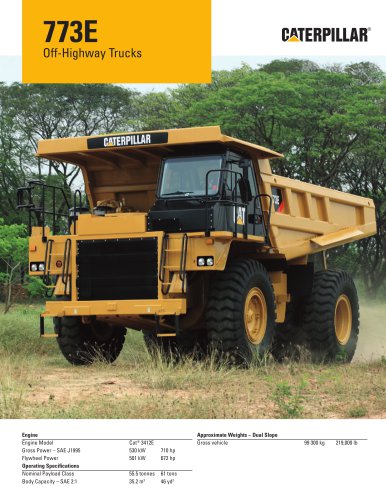

773E

24 Pages

-

772G

28 Pages

-

772

32 Pages

-

770

32 Pages

-

16M

24 Pages

-

14M

28 Pages

-

795F AC

24 Pages

-

793D

32 Pages

-

789D

28 Pages

-

789C

28 Pages

-

HW300

16 Pages

-

785D

24 Pages

-

AEXQ1170 ShovelsBrochure

32 Pages

-

D11T/D11T CD

28 Pages

-

D10T

20 Pages

-

MD6240 Rotary Drill

28 Pages

-

Cat ® Rock Flow System

2 Pages

-

LHD Vehicles Product Line

8 Pages

-

Mining Truck (797F)

28 Pages

-

Motor Grader (16M)

24 Pages

-

Off-Highway Truck (773G)

32 Pages

-

Off-Highway Truck (777G)

36 Pages

-

Open Bowl Scraper (627G)

24 Pages

-

Open Bowl Scraper (627H)

20 Pages

-

Open Bowl Scraper (623H)

20 Pages

-

Open Bowl Scraper (631G)

24 Pages

-

Open Bowl Scraper (621H)

20 Pages

-

Open Bowl Scraper (657G)

24 Pages

-

Longwall Mining Equipment

12 Pages

-

LHD Vehicles

8 Pages

-

CTS Drive Systems

8 Pages

-

Cat® Trucks: The ONE for Mining

28 Pages

-

Belt Systems - Underground

12 Pages

-

Armored Face Conveyors (AFCs)

12 Pages

-

Longwall Automation

12 Pages

-

Cat® track drills MD5150

28 Pages

-

Electric Rope Shovels 7182

3 Pages

-

Cat® track drills MD5125

4 Pages

-

Cat® track drills MD5050 T

4 Pages

-

Cat® track drills MD5090

4 Pages

-

Cat® track drills MD5075

4 Pages

-

Electric Rope Shovels 7295

3 Pages

-

Electric Rope Shovels 7395

3 Pages

-

Cat® track drills MD5050

4 Pages

-

Cat® Rotary drills MD6750

4 Pages

-

Cat® Rotary drills MD6640

4 Pages

-

Electric Rope Shovels 7495

3 Pages

-

Cat® 8750 DRAGLINE RANGE

28 Pages

-

Master Idler

399 Pages

-

Cat® 8200 DRAGLINE RANGE

2 Pages

-

Cat® 8200-127 Dragline

2 Pages

-

Cat® 8200-126 Dragline

2 Pages

-

Cat® 8200-125 Dragline

2 Pages

-

Cat® 8200-124 Dragline

2 Pages

-

Cat® 8200-123 Dragline

2 Pages

-

Cat® 8200-113 Dragline

2 Pages

-

740B EJ articulated track

24 Pages

-

740B articulated track

20 Pages

-

730 ejector articulated track

20 Pages

-

730 articulated track

20 Pages

-

Feeder Breakers

4 Pages

-

Belt Systems & Belt Products

8 Pages

Archived catalogs

-

Draglines

8 Pages

-

988H Wheel Loader

24 Pages

-

844H Wheel Dozer

20 Pages

-

Scoops

8 Pages

-

Face Haulers

12 Pages

-

Continuous Miners

8 Pages

-

Longwall Shearers

16 Pages

-

Roof Support Carriers

12 Pages

-

Roof Support Systems

8 Pages

-

Automated Plow Systems

12 Pages

-

Jumbo Drills

12 Pages

-

Rotary Blasthole Drills

8 Pages

-

Hydraulic Track Drills

8 Pages

-

Hydraulic Shovels

12 Pages

-

Highwall Mining System

8 Pages

-

Electric Rope Shovels

12 Pages

-

Surface Belt Structure

8 Pages