Website:

Caterpillar Global Mining

Website:

Caterpillar Global Mining

Group: Caterpillar

Catalog excerpts

MORE WAYS TO WORK.

Open the catalog to page 1

MORE THAN A MACHINE. A BUSINESS ADVANTAGE. Anyone can buy a machine. But not everyone can turn a profit with it. The reason? You need more than a machine for a successful business. You need answers to questions like these: • What type of material are you moving? • What are the underfoot conditions? • How much material has to be moved? • What is the total job cycle distance? • What are the job site time/production requirements? The answers will suggest certain hauling systems, chosen for their ability to deliver the productivity and profitability you need. Other questions lead to other...

Open the catalog to page 2

WHAT TYPE OF MATERIAL ARE YOU MOVING? Dry or wet? Dirt, sand, gravel or rock? What are the densities of the material? Articulated Trucks 7460 Ejector Rigid Frame Trucks Rubber Tired Ag Tractor Towed Scraper Rubber Tracked Ag Tractor Towed Scraper Track-Type Tractor Towed Scraper Wheel Tractor-Scraper Push Pull Wheel Tractor-Scraper Push Loading Wheel Tractor-Scraper Elevating Wheel Tractor-Scraper Auger Wheel Tractor-Scraper Self-Loading Track-Type Tractor Slot Dozing Wheel Loader Load & Carry Articulated Trucks Ejector Body Articulated Truck When you’re making a serious investment in your...

Open the catalog to page 3

WHAT ABOUT THE UNDERFOOT CONDITIONS? Hard or soft? Smooth haul road or greasy, unimproved surface? 3% – (N Ha o t rd ire Su pe rfa ne ce tra tio 5% n) –5 (2 1m in) m tire pe ne tra 10 tio % n –1 (5 27 in) mm tire pe ne tra tio 15 n % –2 (8 03 in) mm tire pe ne tra 20 tio % n (12 – 30 in) 5 m tire m pe ne tra 30 tio % n (20 – 50 in) 8 m tire m pe ne tra >4 tio 0% n (25 – >6 in) 35 tire m pe m ne tra tio n The answers to these and other similar questions help ensure you get a hauling system that’s optimized for the travel conditions on your worksite. The right system helps maximize job...

Open the catalog to page 4

How much material has to be moved? Your fleet must be properly sized for the amount of material you need to move on the project. Also, to achieve daily production goals, you want to have the equipment within your fleet properly sized and matched to site conditions. What is the total job cycle distance? All Cat® hauling systems are designed and built for endurance. But they are also designed for optimal performance over specific haul lengths. The selection of the proper hauling system for the project improves your production and lowers your cost per load. Optimal Loaded Haul Distances AT...

Open the catalog to page 5

The machines within your hauling system must match each other’s capabilities, as well as the demands of the worksite. For maximum production and efficiency, we recommend that loading tools and hauling tools match to achieve optimal hauling system performance. As a general rule, a hydraulic excavator should load the defined hauler in four to six passes. Wheel loaders should load the matched hauler in three to five passes. What are the job site time/production requirements? Ultimately, every job is a race against time. But it’s a race you can win, time and time again, when your hauling system...

Open the catalog to page 6

No doubt about it—numerous methods to move material exist. Having multiple hauling systems on a single project gives you even more ways to combine them into a productive fleet. Let’s take a look at individual machine capabilities. Articulated Trucks Steep grades, rough terrain and non-existent haul roads call for a hauling unit that can adapt to almost any condition. A Cat® articulated truck delivers productivity in the most inhospitable environments. Preferred solution for: • Projects with tight loading areas and/or vertical cuts • orking in adverse underfoot conditions, including soft cut...

Open the catalog to page 7

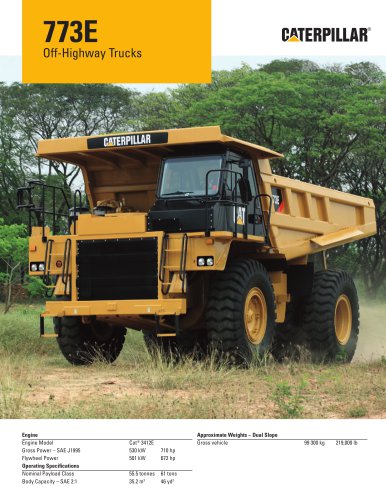

Quarry and Construction Trucks Long hauls and heavy loads call for Cat rigid-frame trucks that are pass-matched to loading tools to improve cycle times and maximize productivity. Preferred solution for: • raveling at high speed along well-maintained haul roads to loading and T dump areas • auling a broad range of material types using different liner packages H • oad times of two minutes or less for optimal production with a L pass-matched wheel loader or hydraulic excavator • anaging long haul distances and varying grades M • arge, multi-year projects, continuous running projects with high...

Open the catalog to page 8

DEDICATED TO YOUR SUCCESS Your hauling system must match your business goals. It must support the work you’re doing today and allow you to adapt as opportunities change. Lifecycle Solutions ROJECT ONS & P RATI NT OPE NAGEME MA NT MAI REPAIR & MENT MANAGE • election: What do I need to efficiently get the job done? S • perations and Project Management: How can I achieve more O productivity and efficiency? • epair and Maintenance Management: How can I develop R capabilities that will lower my risk to obtain optimum life, availability and utilization? • usiness Management: How do I get data to...

Open the catalog to page 9

Managing production costs Caterpillar and Cat dealers are committed to delivering clear, concise and consistent recommendations on hauling system selection. Working with customers around the globe helps us understand different challenges and customer solutions on a regional basis. When you receive a Fleet Production and Cost Analysis from us, you get a recommendation customized to your specific application needs and further refined by the characteristics of your worksite. Our goal is to help you manage your production costs through the acquisition of the optimum hauling system for your...

Open the catalog to page 10

CAT, CATERPILLAR, their respective logos, “Caterpillar Yellow” and the POWER EDGE trade dress, as well as corporate and product identity used herein, are trademarks of Caterpillar and may not be used without permission.

Open the catalog to page 11All Caterpillar Global Mining catalogs and technical brochures

-

D9 DOZER

20 Pages

-

745

28 Pages

-

725C2

28 Pages

-

Cat ® 621K

4 Pages

-

D9T

20 Pages

-

D8T

20 Pages

-

735B Articulated Truck

20 Pages

-

725 Articulated Truck

20 Pages

-

777D

28 Pages

-

775G

32 Pages

-

773E

24 Pages

-

772G

28 Pages

-

772

32 Pages

-

770

32 Pages

-

16M

24 Pages

-

14M

28 Pages

-

795F AC

24 Pages

-

793D

32 Pages

-

789D

28 Pages

-

789C

28 Pages

-

HW300

16 Pages

-

785D

24 Pages

-

AEXQ1170 ShovelsBrochure

32 Pages

-

D11T/D11T CD

28 Pages

-

D10T

20 Pages

-

MD6240 Rotary Drill

28 Pages

-

Cat ® Rock Flow System

2 Pages

-

LHD Vehicles Product Line

8 Pages

-

Mining Truck (797F)

28 Pages

-

Motor Grader (16M)

24 Pages

-

Off-Highway Truck (773G)

32 Pages

-

Off-Highway Truck (777G)

36 Pages

-

Open Bowl Scraper (627G)

24 Pages

-

Open Bowl Scraper (627H)

20 Pages

-

Open Bowl Scraper (623H)

20 Pages

-

Open Bowl Scraper (631G)

24 Pages

-

Open Bowl Scraper (621H)

20 Pages

-

Open Bowl Scraper (657G)

24 Pages

-

Longwall Mining Equipment

12 Pages

-

LHD Vehicles

8 Pages

-

CTS Drive Systems

8 Pages

-

Cat® Trucks: The ONE for Mining

28 Pages

-

Belt Systems - Underground

12 Pages

-

Armored Face Conveyors (AFCs)

12 Pages

-

Longwall Automation

12 Pages

-

Cat® track drills MD5150

28 Pages

-

Electric Rope Shovels 7182

3 Pages

-

Cat® track drills MD5125

4 Pages

-

Cat® track drills MD5050 T

4 Pages

-

Cat® track drills MD5090

4 Pages

-

Cat® track drills MD5075

4 Pages

-

Electric Rope Shovels 7295

3 Pages

-

Electric Rope Shovels 7395

3 Pages

-

Cat® track drills MD5050

4 Pages

-

Cat® Rotary drills MD6750

4 Pages

-

Cat® Rotary drills MD6640

4 Pages

-

Electric Rope Shovels 7495

3 Pages

-

Cat® 8750 DRAGLINE RANGE

28 Pages

-

Master Idler

399 Pages

-

Cat® 8200 DRAGLINE RANGE

2 Pages

-

Cat® 8200-127 Dragline

2 Pages

-

Cat® 8200-126 Dragline

2 Pages

-

Cat® 8200-125 Dragline

2 Pages

-

Cat® 8200-124 Dragline

2 Pages

-

Cat® 8200-123 Dragline

2 Pages

-

Cat® 8200-113 Dragline

2 Pages

-

740B EJ articulated track

24 Pages

-

740B articulated track

20 Pages

-

730 ejector articulated track

20 Pages

-

730 articulated track

20 Pages

-

Feeder Breakers

4 Pages

-

Belt Systems & Belt Products

8 Pages

Archived catalogs

-

Draglines

8 Pages

-

988H Wheel Loader

24 Pages

-

844H Wheel Dozer

20 Pages

-

Scoops

8 Pages

-

Face Haulers

12 Pages

-

Continuous Miners

8 Pages

-

Longwall Shearers

16 Pages

-

Roof Support Carriers

12 Pages

-

Roof Support Systems

8 Pages

-

Automated Plow Systems

12 Pages

-

Jumbo Drills

12 Pages

-

Rotary Blasthole Drills

8 Pages

-

Hydraulic Track Drills

8 Pages

-

Hydraulic Shovels

12 Pages

-

Highwall Mining System

8 Pages

-

Electric Rope Shovels

12 Pages

-

Surface Belt Structure

8 Pages