Catalog excerpts

Moving Mountains No matter how fast your shearer can cut, you can’t keep cutting until you move the coal away from the face. Cat® Armored Face Conveyors (AFCs) are designed to keep things moving and to carry the maximum possible amount of coal smoothly away from the coalface. They are designed for high availability and economy in operation. They are easy to maintain and offer long service life and a great return on investment to mine operators. Best in the Long Run Cat AFCs excel through cutting-edge technology, quality, experience and superior product support. Of course, that’s what any...

Open the catalog to page 2

Meeting all Needs From AFC tail drive to entry belt conveyor return end, Cat AFC systems are designed for a variety of performance requirements in low, medium and high seams, for short and long faces. Caterpillar meets the demand of today’s high-capacity shearers and, of course, our own automated plow systems. The PF Range The line pan is the backbone of the AFC– literally. It not only conveys material from the face, but also acts as the guide rail for the shearer – with traction forces of up to 1 000 kN. Caterpillar offers a range of line pans to suit different needs. These range from the...

Open the catalog to page 3

Engineered to Perfection There are many parts to an Armored Face Conveyor: shearer haulage system, drives, drive frames and sprockets, gearboxes, line pans, chain conveyors as well as entry conveyors and belt tailpieces. Each of these components has to be engineered to perfection, but also has to work together optimally with the other parts of the system. 3D-Simulation of a shearer on a Cat PF6 face conveyor at the head end under extreme bending Cat AFC components achieve this. Each is designed for powerful, reliable and economical operation with low maintenance over a long service life,...

Open the catalog to page 4

Drive Modules The latest development is a drive frame with replaceable one-piece sprocket/shaft/bearing – a “drive module”. These are available in various sizes to suit individual power requirements, right up to 2 x 1 800 kW (2,412 hp) per drive. The drive module is identical for both main and tail drive. The drive frames are independent of the gearboxes used – flange plates and stub shafts are used for interfacing. Two hydraulic cylinders are integrated in the frames for disassembly of the drive module. These are powered by an external pump. There are similar designs for smaller drive...

Open the catalog to page 5

Gearboxes Caterpillar offers gearbox solutions – simple planetary or bevel-spur gearboxes for low-power requirements and the installation of a clutch between motor and gearbox for medium-power installations. The UEL gearbox – a planetary gearbox with an integrated clutch – is designed for higher-power requirements. This friction clutch is closed through face support hydraulic fluid. A hydraulic control system allows the clutch to be set to a certain torque. Overload Protection Overload protection is achieved by measuring the slip of each gearbox. In the event of a chain stall, both motors...

Open the catalog to page 6

PowerChain The wide, arc-shaped cross-section of the vertical links allows a low-profile line pan and the special shape of the horizontal link provides a large running surface where required, drastically reducing surface pressure and chain-joint wear. The method for attaching the flight bar is patented. The PowerChain 42 x 140 mm (1.7 x 5.5 in) has a breaking force of 2 370 kN, the PowerChain 52 x 175 mm (2.0 x 6.9 in) of 3 610 kN. Benefits PowerChain and sprocket in use with a Cat beam stageloader •• Faster removal of mined coal by providing highreliability, high-availability...

Open the catalog to page 7

Line Pans for Every Need Rolled steel is smoother, stronger and harder-wearing than a casting and generates less friction and noise. That’s why Caterpillar has focused on rolled steel designs for line pans. All aspects of the line pans have been engineered with reliability, productivity and serviceability in mind. Maximum Contact Profile shape of PF conveyors The profiles are designed to maximize the contact area between the flight bar and the profile, thus minimizing contact pressure during operation. •• inimizes friction, reduces power requirements for the M face conveyor and results in...

Open the catalog to page 8

Welds without Wear PF5 profile design with wear pattern Cat PF line pans have a rolled profile design. Each of the identical profiles are attached with two welds to the top plate of chosen length and width. This results in great flexibility in pan design. Only one of the welds is located in the wear area of the line pan in the top strand. •• High stability of the pan ensured by three welds even when the top plate is totally worn out Wear-resistant Top Plate The top plate is made of wear-resistant material. The thickness varies from 30 mm (1.2 in) (PF3) to 50 mm (2.0 in) (PF5). •• Long...

Open the catalog to page 9

PF6 – the State-of-the-Art Line Pan Wear is the weak point in line pan design. Hauling millions of tonnes of coal away from the longwall is clearly going to result in high levels of wear. Back in 2002, we decided to try something revolutionary. A group of experts from different countries with many years of experience on various conveyor types was brought together to create a new type of pan that would combine the benefits of rolled and cast line pans to provide an optimum solution to mining industry needs. The First to Really Last and Last The team developed an innovative pan design meeting...

Open the catalog to page 10

Optimized Contact Surfaces Profile of the PF6 shearer line pan The special shaping of the bottom race – which almost doubles the contact surface – reduces flightbar shoulder wear and substantially reduces friction. The curved transition at the pan ends greatly reduces noise during operation of the chain conveyor. •• Minimal friction and power loss, longer flightbar and profile service life, lower noise Maximum Pan Stability The frame of the pan consists of two C profiles connected by a baseplate. Two tried-and-tested PF5 profiles are welded to the bottom plate of the top trough and then...

Open the catalog to page 11All Caterpillar Global Mining catalogs and technical brochures

-

D9 DOZER

20 Pages

-

745

28 Pages

-

725C2

28 Pages

-

Cat ® 621K

4 Pages

-

D9T

20 Pages

-

D8T

20 Pages

-

735B Articulated Truck

20 Pages

-

725 Articulated Truck

20 Pages

-

777D

28 Pages

-

775G

32 Pages

-

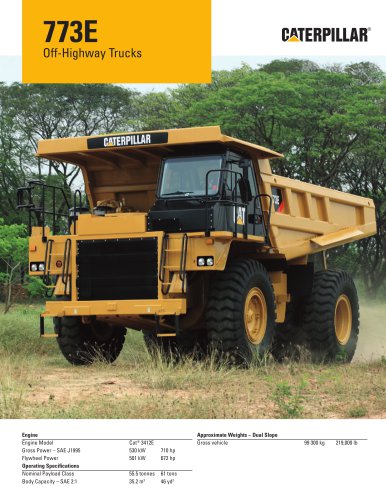

773E

24 Pages

-

772G

28 Pages

-

772

32 Pages

-

770

32 Pages

-

16M

24 Pages

-

14M

28 Pages

-

795F AC

24 Pages

-

793D

32 Pages

-

789D

28 Pages

-

789C

28 Pages

-

HW300

16 Pages

-

785D

24 Pages

-

AEXQ1170 ShovelsBrochure

32 Pages

-

D11T/D11T CD

28 Pages

-

D10T

20 Pages

-

MD6240 Rotary Drill

28 Pages

-

Cat ® Rock Flow System

2 Pages

-

LHD Vehicles Product Line

8 Pages

-

Mining Truck (797F)

28 Pages

-

Motor Grader (16M)

24 Pages

-

Off-Highway Truck (773G)

32 Pages

-

Off-Highway Truck (777G)

36 Pages

-

Open Bowl Scraper (627G)

24 Pages

-

Open Bowl Scraper (627H)

20 Pages

-

Open Bowl Scraper (623H)

20 Pages

-

Open Bowl Scraper (631G)

24 Pages

-

Open Bowl Scraper (621H)

20 Pages

-

Open Bowl Scraper (657G)

24 Pages

-

Longwall Mining Equipment

12 Pages

-

LHD Vehicles

8 Pages

-

CTS Drive Systems

8 Pages

-

Cat® Trucks: The ONE for Mining

28 Pages

-

Belt Systems - Underground

12 Pages

-

Longwall Automation

12 Pages

-

Cat® track drills MD5150

28 Pages

-

Electric Rope Shovels 7182

3 Pages

-

Cat® track drills MD5125

4 Pages

-

Cat® track drills MD5050 T

4 Pages

-

Cat® track drills MD5090

4 Pages

-

Cat® track drills MD5075

4 Pages

-

Electric Rope Shovels 7295

3 Pages

-

Electric Rope Shovels 7395

3 Pages

-

Cat® track drills MD5050

4 Pages

-

Cat® Rotary drills MD6750

4 Pages

-

Cat® Rotary drills MD6640

4 Pages

-

Electric Rope Shovels 7495

3 Pages

-

Cat® 8750 DRAGLINE RANGE

28 Pages

-

Master Idler

399 Pages

-

Cat® 8200 DRAGLINE RANGE

2 Pages

-

Cat® 8200-127 Dragline

2 Pages

-

Cat® 8200-126 Dragline

2 Pages

-

Cat® 8200-125 Dragline

2 Pages

-

Cat® 8200-124 Dragline

2 Pages

-

Cat® 8200-123 Dragline

2 Pages

-

Cat® 8200-113 Dragline

2 Pages

-

740B EJ articulated track

24 Pages

-

740B articulated track

20 Pages

-

730 ejector articulated track

20 Pages

-

730 articulated track

20 Pages

-

Feeder Breakers

4 Pages

-

Belt Systems & Belt Products

8 Pages

Archived catalogs

-

Draglines

8 Pages

-

988H Wheel Loader

24 Pages

-

844H Wheel Dozer

20 Pages

-

Scoops

8 Pages

-

Face Haulers

12 Pages

-

Continuous Miners

8 Pages

-

Longwall Shearers

16 Pages

-

Roof Support Carriers

12 Pages

-

Roof Support Systems

8 Pages

-

Automated Plow Systems

12 Pages

-

Jumbo Drills

12 Pages

-

Rotary Blasthole Drills

8 Pages

-

Hydraulic Track Drills

8 Pages

-

Hydraulic Shovels

12 Pages

-

Highwall Mining System

8 Pages

-

Electric Rope Shovels

12 Pages

-

Surface Belt Structure

8 Pages