Catalog excerpts

Engine Model Cat® C175-16 Operating Specifications Nominal Payload Capacity 313 tonnes 345 tons Gross Machine Operating Weight (GMW) 570 678 kg 1,257,0001b

Open the catalog to page 1

795F AC Features High Performance Engine The Cat® C175-16 engine offers the perfect balance between power, robust design and economy. Focus on Safety Wide access stairways, standard object detection, industry leading dynamic retarding, four corner wet disc brakes and traction control with automatic front brake assist inspire operator confidence. Enhanced Serviceability Modular components, grouped service locations and more ground accessible maintenance points translate into less downtime. Reliable AC Electric Drive System The Cat AC electric drive power train is 100% Caterpillar designed,...

Open the catalog to page 2

Power Train – Engine The Cat® C175-16 engine is built for power, reliability and efficiency. Engine The Cat® C175-16 quad turbocharged and air-to-air aftercooled diesel engine has enhanced power management capability for maximum hauling performance in the most demanding mining applications. Design The C175-16 is a 16-cylinder, four-stroke design that uses long, effective power strokes for optimum efficiency. EPA Compliant The Cat C175-16 engine is compliant with U.S. Environmental Protection Agency Tier 2 emissions requirements. Variable Cooling Variable fan speed directs maximum power to...

Open the catalog to page 3

Power Train – Cat AC Electric Drive More power to the ground for greater productivity. Why Electric Drive? Cat mechanical drive trucks are the standard of the industry and are favored in most applications. Some customers, however, prefer electric drive for specific applications and situations. 100% Caterpillar Designed and manufactured by Caterpillar, the 795 is the first AC electric drive truck that is single sourced from one manufacturer and supported by the best dealer network in the industry. The 795 power train works seamlessly with the C-175 engine and offers unsurpassed Safety,...

Open the catalog to page 4

Cat AC Electric Drive in Retard During retarding the wheel motors become generators. Motor power is fed back through the DC link. The power is fed to the contactor and chopper circuits and then exhausted through the radial grid. An AC fan blows air across the grid to dissipate the power and control retarding speed. Generator/Alternator The chassis mounted 795F AC traction generator is a threephase, two bearing design. The excitation system is brushless which has longer maintenance intervals than brush type systems. Inverter The Inverter uses Mitsubishi Electric IGBT Phase Modules to control...

Open the catalog to page 5

Engine/Power Train Integration Electronically combined power train components optimize performance. Control Software and Integration Caterpillar links the power train components with a complete system of proprietary software. The 100% Caterpillar design allows the software developers full access to all subsystems. The result is a control and integration package that works seamlessly. The 795 is simple to learn and simple to operate. In addition, the truck has excellent operating traits. • Excellent slow speed control for safety within the service areas. Excellent throttle response on...

Open the catalog to page 6

Superior braking control lets operators focus on productivity. Industry Leading Dynamic Retarding The radial grid is rated at 4.75 MW (6,365 hp) – allowing excellent control of the truck speed in long retarding applications. The radial design is light, efficient and quiet. Four Corner Oil Cooled Brakes for Additional Retarding In addition to class leading dynamic retarding – Cat four corner, oil cooled service brakes give additional retarding capability. These are the same sized brakes used on the 797. The 795 offers exceptional non-fade braking and supplemental retarding at all speeds....

Open the catalog to page 7

Building on the legacy of superior, long life structures. Box Section Design The 795F AC uses a box-section design, incorporating forgings and castings in high stress areas with deep penetration, continuous wrap-around welds to resist fatigue from racking loads. Steel Structures – Mild steel used throughout the frame provides flexibility, durability and resistance to impact and allows for field repairs with common weld practices. Castings – Large radii castings dissipate stress in areas of high stress concentration. Castings allow welds to be placed in lower stress areas for longer frame...

Open the catalog to page 8

Truck Body Systems Caterpillar designed and built for rugged performance and reliability. Cat Bodies for Cat Trucks Integral to the truck the body is designed to fit with the chassis and work as part of the truck system. Each body is sized to meet the payload requirements without compromise to vehicle balance, braking or control. Cat Body Choices Body options include the popular MSD II (Mine Specific Design) and Gateless Coal Bodies. Liner options fit the body to the application. MSD II Body – Based on a mine site evaluation the body is sized and configured to meet the specific needs...

Open the catalog to page 9

Monitoring System Vital machine health and payload data for the operator. VIMS™ 3G Monitoring System Provides critical health and payload information in real-time to keep the 795 performing at optimum levels. VIMS is able to monitor information from all vehicle systems. 10 different machine parameters can be viewed at once. Data can be downloaded easily by Service Technicians for troubleshooting, planning and lowering costs. Advisor Display The Advisor display provides real-time performance, maintenance and diagnostic data to the operator or service technician. A large number of machine...

Open the catalog to page 10

Operator’s Station Ergonomically designed for all-day comfort, control and productivity. Enhanced Operator Awareness The standard Cat Detect system uses Radar and Cameras to give the operator audible alarms and visual awareness of detected objects at start up and low speeds. This shows a strong commitment to operator and operational safety. Ergonomic Cab Layout Controls are intuitive and within easy reach making the operator more comfortable, productive and safe. Operator feedback for the 795 is easy to learn and easy to control. Viewing Area The large viewing area offers exceptional...

Open the catalog to page 11All Caterpillar Global Mining catalogs and technical brochures

-

D9 DOZER

20 Pages

-

745

28 Pages

-

725C2

28 Pages

-

Cat ® 621K

4 Pages

-

D9T

20 Pages

-

D8T

20 Pages

-

735B Articulated Truck

20 Pages

-

725 Articulated Truck

20 Pages

-

777D

28 Pages

-

775G

32 Pages

-

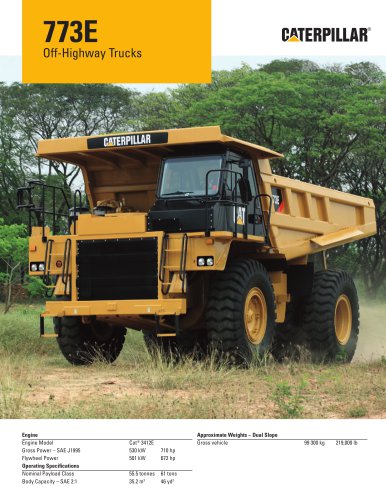

773E

24 Pages

-

772G

28 Pages

-

772

32 Pages

-

770

32 Pages

-

16M

24 Pages

-

14M

28 Pages

-

793D

32 Pages

-

789D

28 Pages

-

789C

28 Pages

-

HW300

16 Pages

-

785D

24 Pages

-

AEXQ1170 ShovelsBrochure

32 Pages

-

D11T/D11T CD

28 Pages

-

D10T

20 Pages

-

MD6240 Rotary Drill

28 Pages

-

Cat ® Rock Flow System

2 Pages

-

LHD Vehicles Product Line

8 Pages

-

Mining Truck (797F)

28 Pages

-

Motor Grader (16M)

24 Pages

-

Off-Highway Truck (773G)

32 Pages

-

Off-Highway Truck (777G)

36 Pages

-

Open Bowl Scraper (627G)

24 Pages

-

Open Bowl Scraper (627H)

20 Pages

-

Open Bowl Scraper (623H)

20 Pages

-

Open Bowl Scraper (631G)

24 Pages

-

Open Bowl Scraper (621H)

20 Pages

-

Open Bowl Scraper (657G)

24 Pages

-

Longwall Mining Equipment

12 Pages

-

LHD Vehicles

8 Pages

-

CTS Drive Systems

8 Pages

-

Cat® Trucks: The ONE for Mining

28 Pages

-

Belt Systems - Underground

12 Pages

-

Armored Face Conveyors (AFCs)

12 Pages

-

Longwall Automation

12 Pages

-

Cat® track drills MD5150

28 Pages

-

Electric Rope Shovels 7182

3 Pages

-

Cat® track drills MD5125

4 Pages

-

Cat® track drills MD5050 T

4 Pages

-

Cat® track drills MD5090

4 Pages

-

Cat® track drills MD5075

4 Pages

-

Electric Rope Shovels 7295

3 Pages

-

Electric Rope Shovels 7395

3 Pages

-

Cat® track drills MD5050

4 Pages

-

Cat® Rotary drills MD6750

4 Pages

-

Cat® Rotary drills MD6640

4 Pages

-

Electric Rope Shovels 7495

3 Pages

-

Cat® 8750 DRAGLINE RANGE

28 Pages

-

Master Idler

399 Pages

-

Cat® 8200 DRAGLINE RANGE

2 Pages

-

Cat® 8200-127 Dragline

2 Pages

-

Cat® 8200-126 Dragline

2 Pages

-

Cat® 8200-125 Dragline

2 Pages

-

Cat® 8200-124 Dragline

2 Pages

-

Cat® 8200-123 Dragline

2 Pages

-

Cat® 8200-113 Dragline

2 Pages

-

740B EJ articulated track

24 Pages

-

740B articulated track

20 Pages

-

730 ejector articulated track

20 Pages

-

730 articulated track

20 Pages

-

Feeder Breakers

4 Pages

-

Belt Systems & Belt Products

8 Pages

Archived catalogs

-

Draglines

8 Pages

-

988H Wheel Loader

24 Pages

-

844H Wheel Dozer

20 Pages

-

Scoops

8 Pages

-

Face Haulers

12 Pages

-

Continuous Miners

8 Pages

-

Longwall Shearers

16 Pages

-

Roof Support Carriers

12 Pages

-

Roof Support Systems

8 Pages

-

Automated Plow Systems

12 Pages

-

Jumbo Drills

12 Pages

-

Rotary Blasthole Drills

8 Pages

-

Hydraulic Track Drills

8 Pages

-

Hydraulic Shovels

12 Pages

-

Highwall Mining System

8 Pages

-

Electric Rope Shovels

12 Pages

-

Surface Belt Structure

8 Pages