Catalog excerpts

Mining Truck Engine (options) Engine Model Gross Power – SAE J1995 Rated Net Power – ISO 9249 Engine Model Gross Power – SAE J1995 Net Power – SAE J1349 Weights – Approximate Gross Machine Operating Weight (GMW) Operating Specifications Nominal Payload Capacity

Open the catalog to page 1

Caterpillar’s exclusive design ownership provides advantages by creating a total hauling unit that delivers the best integration of high production, availability, and payload in combination with low operating cost and long life. The Cat® 789D continues the tradition of Caterpillar’s proven 789 Truck with high productivity and lowest in class cost per ton. The 789D features the following: • Safety and Sustainability. Safety is top priority. Engine options to meet regulatory requirements or application specific needs. Production capability with nominal payload capacity of 181 metric tons (200...

Open the catalog to page 2

Power Train – Engine The Cat ® 3500 series engines are built for power, reliability and efficiency for superior performance in the toughest applications. Engine Both the Cat® 3516B and 3516C EUI Quad turbocharged diesel engines deliver high power and reliability in the world’s most demanding mining applications. Design The 3500 series engines are 16-cylinder, four-stroke designs that uses long, effective power strokes for more complete fuel combustion and optimum efficiency. EPA Compliant Where applicable, the 3516C engine is compliant with U.S. Environmental Protection Agency emissions...

Open the catalog to page 3

Power Train – Transmission Cat mechanical power train delivers more power to the ground for greater productivity and lower operating costs. Mechanical Power Train The Cat mechanical drive power train and power shift transmission provides unmatched operating efficiency and control on steep grades, in poor underfoot conditions, and on haul roads with high rolling resistance. 1) Transmission The Cat six-speed planetary power shift transmission is matched with the direct-injection 3516 diesel engine to deliver constant power over a wide range of operating speeds. Robust Design Designed for the...

Open the catalog to page 4

Engine/Power Train Integration Electronically combines critical power train components to work more intelligently and to optimize overall truck performance. Cat Data Link Electronically integrates machine computer systems to optimize overall power train performance, increase reliability and component life, and reduce operating costs. Electronic Technician (Cat ET) Cat ET service tool provides service technicians with easy access to stored diagnostic data through the Cat Data Link to simplify problem diagnosis and increase machine availability. Integrated Braking Control (IBC) Integrates...

Open the catalog to page 5

Rugged Cat structures are the backbone of the 789D mining truck’s durability. Box-Section Design The 789D frame uses a box-section design, incorporating two forgings and 21 castings in high stress areas with deep penetrating and continuous wrap-around welds to resist damage from twisting loads without adding extra weight. Serviceability The open box-section frame design allows easy access to power train components, reducing overall removal and installation time, and lowering overall repair costs. The raised and pinned body allows excellent access to the transmission. Steel Structures Mild...

Open the catalog to page 6

Operator’s Station Ergonomically designed for operator comfort, superior control, and high productivity. Operator Environment Through the packaging of popular attachments into arrangements, customers can now select one cab that is equipped with desired features. Available offerings include a Standard Cab, Deluxe Cab or Deluxe Cold Weather Cab. 1) Air Suspension Seat with Three-Point Operator Restraint 2) Parking Brake Reset Valve 3) Trainer Seat 4) Storage Compartment 5) Operator Window 6) Secondary Brake Pedal 7) Transmission Console 8) Operator Controls 9) Adjustable Steering Wheel/Column...

Open the catalog to page 7

Cat® Brake System Reliable braking with superior control gives the operator the confidence to focus on productivity. Integrated Braking System The Cat oil-cooled braking system delivers reliable performance and control in the most extreme haul road conditions. The integrated system combines the service, secondary, parking brake and retarding functions in the same robust system for optimum braking efficiency. Four Corner Retarding Four corner retarding with 60/40 percent split (rear/front) in braking effort provides superior control in slippery conditions. Balanced front to rear brake torque...

Open the catalog to page 8

Truck Body Systems Cat designed and built for rugged performance and reliability in the toughest mining applications. Cat Truck Bodies Matching the truck body to the application is a critical part of achieving the best value from your 789D. Caterpillar offers a variety of application specific body options that yield a payload ranging from 177 to 188 metric tons (195 to 207 tons). The Caterpillar exclusive 10/10/20 payload guidelines help achieve a balance of excellent payload with safe operation. Body Options 1) Cat “X” Body – The X body is a heavy duty body configured with a variety of...

Open the catalog to page 9

Monitoring System Vital machine health and payload data keeps the 789D performing at peak production levels. VIMS PC VIMS™ Monitoring System Intelligent Caterpillar designed machine monitoring system provides critical machine health and payload data in realtime to keep the 789D performing at top production levels. This system is translated and available in most of the major international languages. Production Management Production Management enhances truck/loading tool effectiveness, improves fleet productivity and helps extend the life of truck frames, tires, rims and power train...

Open the catalog to page 10

Cat mining machines and systems are designed with safety as their first priority. Product Safety Caterpillar has been and continues to be proactive in developing mining machines that meet or exceed safety standards. Safety is an integral part of all machine and system designs. Mining Technologies Cat® MineStar™ System encompasses a comprehensive suite of mining technologies grouped within a number of configurable capability sets, including Fleet, Terrain, Detect, Health, and Command. Object Detection is part of the Detect capability set and provides customers with a scalable system to aid...

Open the catalog to page 11All Caterpillar Global Mining catalogs and technical brochures

-

D9 DOZER

20 Pages

-

745

28 Pages

-

725C2

28 Pages

-

Cat ® 621K

4 Pages

-

D9T

20 Pages

-

D8T

20 Pages

-

735B Articulated Truck

20 Pages

-

725 Articulated Truck

20 Pages

-

777D

28 Pages

-

775G

32 Pages

-

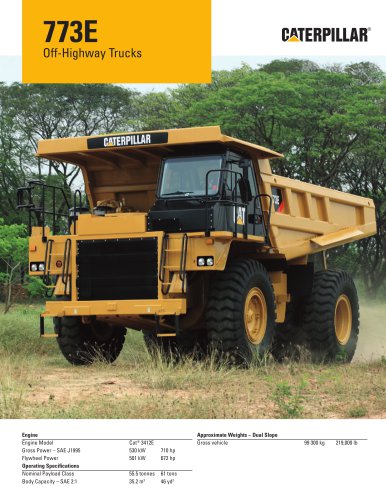

773E

24 Pages

-

772G

28 Pages

-

772

32 Pages

-

770

32 Pages

-

16M

24 Pages

-

14M

28 Pages

-

795F AC

24 Pages

-

793D

32 Pages

-

789C

28 Pages

-

HW300

16 Pages

-

785D

24 Pages

-

AEXQ1170 ShovelsBrochure

32 Pages

-

D11T/D11T CD

28 Pages

-

D10T

20 Pages

-

MD6240 Rotary Drill

28 Pages

-

Cat ® Rock Flow System

2 Pages

-

LHD Vehicles Product Line

8 Pages

-

Mining Truck (797F)

28 Pages

-

Motor Grader (16M)

24 Pages

-

Off-Highway Truck (773G)

32 Pages

-

Off-Highway Truck (777G)

36 Pages

-

Open Bowl Scraper (627G)

24 Pages

-

Open Bowl Scraper (627H)

20 Pages

-

Open Bowl Scraper (623H)

20 Pages

-

Open Bowl Scraper (631G)

24 Pages

-

Open Bowl Scraper (621H)

20 Pages

-

Open Bowl Scraper (657G)

24 Pages

-

Longwall Mining Equipment

12 Pages

-

LHD Vehicles

8 Pages

-

CTS Drive Systems

8 Pages

-

Cat® Trucks: The ONE for Mining

28 Pages

-

Belt Systems - Underground

12 Pages

-

Armored Face Conveyors (AFCs)

12 Pages

-

Longwall Automation

12 Pages

-

Cat® track drills MD5150

28 Pages

-

Electric Rope Shovels 7182

3 Pages

-

Cat® track drills MD5125

4 Pages

-

Cat® track drills MD5050 T

4 Pages

-

Cat® track drills MD5090

4 Pages

-

Cat® track drills MD5075

4 Pages

-

Electric Rope Shovels 7295

3 Pages

-

Electric Rope Shovels 7395

3 Pages

-

Cat® track drills MD5050

4 Pages

-

Cat® Rotary drills MD6750

4 Pages

-

Cat® Rotary drills MD6640

4 Pages

-

Electric Rope Shovels 7495

3 Pages

-

Cat® 8750 DRAGLINE RANGE

28 Pages

-

Master Idler

399 Pages

-

Cat® 8200 DRAGLINE RANGE

2 Pages

-

Cat® 8200-127 Dragline

2 Pages

-

Cat® 8200-126 Dragline

2 Pages

-

Cat® 8200-125 Dragline

2 Pages

-

Cat® 8200-124 Dragline

2 Pages

-

Cat® 8200-123 Dragline

2 Pages

-

Cat® 8200-113 Dragline

2 Pages

-

740B EJ articulated track

24 Pages

-

740B articulated track

20 Pages

-

730 ejector articulated track

20 Pages

-

730 articulated track

20 Pages

-

Feeder Breakers

4 Pages

-

Belt Systems & Belt Products

8 Pages

Archived catalogs

-

Draglines

8 Pages

-

988H Wheel Loader

24 Pages

-

844H Wheel Dozer

20 Pages

-

Scoops

8 Pages

-

Face Haulers

12 Pages

-

Continuous Miners

8 Pages

-

Longwall Shearers

16 Pages

-

Roof Support Carriers

12 Pages

-

Roof Support Systems

8 Pages

-

Automated Plow Systems

12 Pages

-

Jumbo Drills

12 Pages

-

Rotary Blasthole Drills

8 Pages

-

Hydraulic Track Drills

8 Pages

-

Hydraulic Shovels

12 Pages

-

Highwall Mining System

8 Pages

-

Electric Rope Shovels

12 Pages

-

Surface Belt Structure

8 Pages