Catalog excerpts

Operating Specifications Nominal Payload 90.4 tonnes 100 tons • Refer to the Caterpillar® 10/10/20 Payload Guidelines. Weights - Approximate Target Gross Machine 163 360 kg 360,143 lb Operating Weight

Open the catalog to page 1

777D Off-Highway Truck Engineered for performance, designed for comfort, built to last. Power Train – Engine Power Train – Transmission Engine/Power Train Integration The Cat 3508B EUI engine delivers the power and reliability necessary to perform in the most demanding applications. Designed for efficient operation, the 3508B offers excellent fuel efficiency, lower emissions, reduced engine noise and lower operating costs. pg. 4 The Cat seven-speed power shift transmission, matched with the 3508B electronic unit injection engine, provides consistent power and efficiency over a wide...

Open the catalog to page 2

Brake System Cat rear oil-cooled, multiple disc brakes offer exceptional, fade-resistant braking and retarding for maximum performance and productivity in all haul road conditions. Optional Automatic Retarder Control and Traction Control Systems provide optimum braking efficiency. pg. 8 Caterpillar truck frames are built to resist twisting in the most severe, high impact applications. Mild steel provides flexibility, durability and resistance to impact loads. Castings and forgings in high stress areas provide exceptional strength and durability for long life. pg. 10 The ergonomic cab is...

Open the catalog to page 3

Power Train – Engine The Cat 3508B engine is built for power, reliability and efficiency for superior performance in the toughest applications. 1 Electronic Unit Injection 2 Two-Piece Pistons 3 Separate Circuit Aftercooler 4 Valve Rotators 5 Oil Cooler 6 Self-Aligning Roller Followers 7 Steel-Backed Copper Bonded Bearings Engine. The Cat 3508B EUI twin turbocharged and aftercooled diesel engine delivers high power and reliability in the world’s most demanding applications. The 3508B is an eightcylinder, four-stroke design that uses long, effective power strokes for more complete fuel...

Open the catalog to page 4

Power Train – Transmission Cat power train delivers more power to the ground for greater productivity and lower operating costs. 1) Transmission. The Cat seven-speed planetary power shift transmission is matched with the direct-injection 3508B diesel engine to deliver constant power over a wide range of operating speeds. Robust Design. Designed for the higher horsepower of the 3508B engine, the proven planetary power shift transmission is built tough for long life between overhauls. Long Life. A dedicated oil tank and circuit provides cooler, cleaner oil for maximum performance and longer...

Open the catalog to page 5

Engine/Power Train Integration Electronically combines critical power train components to work more intelligently to optimize overall truck performance. 1 Electronic Technician 2 CAT Data Link 3 Sensors 4 Engine Control Module (ECM) 5 Transmission Chassis Control (TCC) 6 Automatic Retarder Control (ARC) Traction Control System (TCS) 6 Integrated Brake Control (IBC) 7 Electronic Monitoring System (EMS III) Display 8 Transmission 9 Oil-Cooled Rear Brakes 10 Oil-Cooled Front Brakes (if equipped) Cat Data Link. Electronically integrates machine computer systems to optimize overall power train...

Open the catalog to page 6

• Overspeed Protection. The transmission control electronically senses engine conditions and automatically up-shifts one gear to prevent overspeeding. If overspeeding occurs in top gear, the lock-up clutch is disengaged. Electronic Monitoring System (EMS III). EMS III allows the operator to view requested information and utilizes a three-category warning system to alert the operator of abnormal machine conditions. Data can be downloaded via the Electronic Technician (ET) service tool for quick diagnosis and repair. • Programmable Top Gear. Transmission top gear maximum can be set using the...

Open the catalog to page 7

Brake System Reliable braking with superior control gives the operator the confidence to focus on productivity. Pistons. The Caterpillar two-piston design combines the service, secondary, parking brake and retarding functions in the same system. The primary piston hydraulically actuates both service and retarding functions. The secondary piston is spring-applied and held in the disengaged position by hydraulic pressure. If hydraulic system pressure drops below a specified level, the spring-applied secondary piston automatically applies the brakes. Parking Brake. Oil-cooled, springapplied,...

Open the catalog to page 8

Service Brake Sensor Engine Sensor ARC ARC Switch Brakes Service Brakes Axle Speed Sensor TCS • Superior Control. Automatic brake modulation offers a smoother ride and better control in slippery conditions, allowing the operating to concentrate on driving. • Fuel Efficiency. During retarding applications the engine ECM does not inject fuel into the cylinders for additional fuel economy. Four Corner Retarding. If equipped with front oil cooled disc brake, four corner retarding with 60/40 percent split (rear/front) in braking effort provides superior control in slippery conditions. Balanced...

Open the catalog to page 9

Structures Rugged Cat structures are the backbone of the 777D off-highway truck’s durability. Steering System. A twin double-acting cylinder steering system is designed to deliver precise control under all loading and underfoot conditions. The steering system is separate from the main hydraulic system to prevent crosscontamination and overheating from other sources. Supplemental Steering. Main hydraulic steering system is backed by a battery powered supplemental steering system which uses pressure accumulators and allows up to three 90 degree turns in case of engine failure. System...

Open the catalog to page 10

Ride Control. Built-in rebound control and strategically located cab relative to the front axle minimizes the effect of pitch and bounce, resulting in a more comfortable ride, higher productivity and less fatigue. 1 Nitrogen 2 Oil 3 Rebound Chamber 4 Cylinder Housing 5 Piston

Open the catalog to page 11

Operator’s Station Ergonomically designed for operator comfort, superior control and high productivity. 7) Operator Controls. Easy to reach turn signal, high beam, windshield wiper/washer, and retarder controls are designed for optimum efficiency and comfort. 8) Storage Compartment. Large compartment located under the trainer seat provides an uncluttered working environment. 9) Trainer Seat. Full-size, fully padded trainer seat features a backrest, wide hip and shoulder room, and seat belt for secure travel. 1 10) Monitoring System. Electronic Monitoring System (EMS III) features...

Open the catalog to page 12All Caterpillar Global Mining catalogs and technical brochures

-

D9 DOZER

20 Pages

-

745

28 Pages

-

725C2

28 Pages

-

Cat ® 621K

4 Pages

-

D9T

20 Pages

-

D8T

20 Pages

-

735B Articulated Truck

20 Pages

-

725 Articulated Truck

20 Pages

-

775G

32 Pages

-

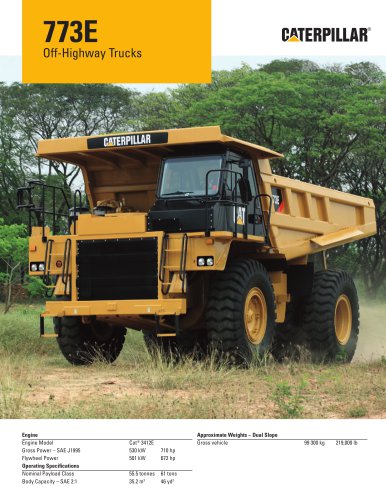

773E

24 Pages

-

772G

28 Pages

-

772

32 Pages

-

770

32 Pages

-

16M

24 Pages

-

14M

28 Pages

-

795F AC

24 Pages

-

793D

32 Pages

-

789D

28 Pages

-

789C

28 Pages

-

HW300

16 Pages

-

785D

24 Pages

-

AEXQ1170 ShovelsBrochure

32 Pages

-

D11T/D11T CD

28 Pages

-

D10T

20 Pages

-

MD6240 Rotary Drill

28 Pages

-

Cat ® Rock Flow System

2 Pages

-

LHD Vehicles Product Line

8 Pages

-

Mining Truck (797F)

28 Pages

-

Motor Grader (16M)

24 Pages

-

Off-Highway Truck (773G)

32 Pages

-

Off-Highway Truck (777G)

36 Pages

-

Open Bowl Scraper (627G)

24 Pages

-

Open Bowl Scraper (627H)

20 Pages

-

Open Bowl Scraper (623H)

20 Pages

-

Open Bowl Scraper (631G)

24 Pages

-

Open Bowl Scraper (621H)

20 Pages

-

Open Bowl Scraper (657G)

24 Pages

-

Longwall Mining Equipment

12 Pages

-

LHD Vehicles

8 Pages

-

CTS Drive Systems

8 Pages

-

Cat® Trucks: The ONE for Mining

28 Pages

-

Belt Systems - Underground

12 Pages

-

Armored Face Conveyors (AFCs)

12 Pages

-

Longwall Automation

12 Pages

-

Cat® track drills MD5150

28 Pages

-

Electric Rope Shovels 7182

3 Pages

-

Cat® track drills MD5125

4 Pages

-

Cat® track drills MD5050 T

4 Pages

-

Cat® track drills MD5090

4 Pages

-

Cat® track drills MD5075

4 Pages

-

Electric Rope Shovels 7295

3 Pages

-

Electric Rope Shovels 7395

3 Pages

-

Cat® track drills MD5050

4 Pages

-

Cat® Rotary drills MD6750

4 Pages

-

Cat® Rotary drills MD6640

4 Pages

-

Electric Rope Shovels 7495

3 Pages

-

Cat® 8750 DRAGLINE RANGE

28 Pages

-

Master Idler

399 Pages

-

Cat® 8200 DRAGLINE RANGE

2 Pages

-

Cat® 8200-127 Dragline

2 Pages

-

Cat® 8200-126 Dragline

2 Pages

-

Cat® 8200-125 Dragline

2 Pages

-

Cat® 8200-124 Dragline

2 Pages

-

Cat® 8200-123 Dragline

2 Pages

-

Cat® 8200-113 Dragline

2 Pages

-

740B EJ articulated track

24 Pages

-

740B articulated track

20 Pages

-

730 ejector articulated track

20 Pages

-

730 articulated track

20 Pages

-

Feeder Breakers

4 Pages

-

Belt Systems & Belt Products

8 Pages

Archived catalogs

-

Draglines

8 Pages

-

988H Wheel Loader

24 Pages

-

844H Wheel Dozer

20 Pages

-

Scoops

8 Pages

-

Face Haulers

12 Pages

-

Continuous Miners

8 Pages

-

Longwall Shearers

16 Pages

-

Roof Support Carriers

12 Pages

-

Roof Support Systems

8 Pages

-

Automated Plow Systems

12 Pages

-

Jumbo Drills

12 Pages

-

Rotary Blasthole Drills

8 Pages

-

Hydraulic Track Drills

8 Pages

-

Hydraulic Shovels

12 Pages

-

Highwall Mining System

8 Pages

-

Electric Rope Shovels

12 Pages

-

Surface Belt Structure

8 Pages