Website:

Caterpillar Global Mining

Website:

Caterpillar Global Mining

Group: Caterpillar

Catalog excerpts

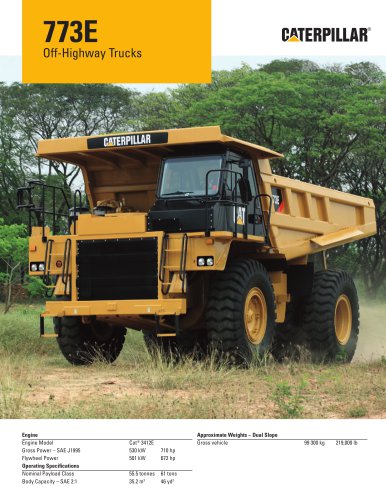

Off-Highway Truck Engine Engine Model Gross Power – SAE J1995 Net Power – SAE J1349 Weights – Approximate Target Gross Machine Operating Weight Operating Specifications Nominal Payload Class (100%) Maximum Working Payload (110%) Not to Exceed Payload* (120%) Body Capacity – SAE 2:1 • Nominal payload and capacity based on Quarry Body. Liner and attachment selection will affect payload and maximum gross machine operating weight. * Refer to Caterpillar® 10/10/20 Payload Policy for maximum gross machine weight limitations.

Open the catalog to page 1

772 Off-Highway Truck Engineered for performance, designed for comfort, built to last. Power Train – Engine Power Train – Transmission The Cat® C18 engine with ACERT™ Technology uses advanced engine technology to reduce emissions without after-treatment. The turbocharged, aftercooled 6-cylinder engine has faster response for superior performance in demanding applications. pg. 4 The Cat® seven-speed power shift transmission matched with the Cat C18 engine with ACERT Technology provides constant power and efficiency over a wide operating speed range for optimal power train performance. pg. 6...

Open the catalog to page 2

Operator’s Station Engine – Power Train Integration Brake System The 772 features an all new operator station with enhanced visibility, increased operator space and ergonomically designed controls that set new industry standards for operator comfort. All controls and gauges are positioned for optimum efficiency and total machine control. pg. 9 The Cat Data Link electronically combines engine, transmission, brake and operational information to optimize overall truck performance. Stored diagnostic data can be accessed via the Cat Electronic Technician (Cat ET) service tool to improve...

Open the catalog to page 3

Power Train – Engine The Cat® C18 engine with ACERT™ Technology is built for power, reliability and efficiency for superior performance in the toughest applications. Overhead Cam. A single overhead cam is driven by gears on the front of the engine, which significantly reduce noise and vibration. Caterpillar also has added two pendulum absorbers, mounted at the front of the camshafts to further reduce noise and vibration. Pistons, Connecting Rods, Cylinder Liners. New design and material improvements to the pistons, rods and liners have been made to support the higher cylinder pressures and...

Open the catalog to page 4

Turbochargers. The single, waste-gated turbocharger found on the C18 engine is water-cooled to accommodate sudden hot machine shutdowns. Water cools the bearings during this event, preventing bearing seizure. The C18 engine also includes a new turbine housing and an additional spacer bearing. The addition of a spacer bearing eliminates snap rings and, therefore, reduces complexity and improves shaft motion. The turbocharger for the 772 features a titanium compression wheel. The titanium compression wheel is used to withstand the higher compression wheel speeds that are required, especially...

Open the catalog to page 5

Power Train – Transmission Cat power train delivers more power to the ground for greater productivity and lower operating costs. Lock-Up Torque Converter. Combines maximum rimpull and cushioned shifting of torque converter drive with the efficiency and performance of direct drive. The torque converter includes an additional clutch plate to maintain power train capability for higher horsepower and top speed, as well as a new torque converter adapter that provides extra length to house the additional clutch plate and enables the converter components to be changed without having to change the...

Open the catalog to page 6

New A-Frame. The new A-frame mounts directly to the spindles. The new A-frame eliminates the “king” bolt and includes a pin and bushing style mounting, consistent with the 777 and 793. This new design is simpler to maintain and service. New Ductile Iron Spindles. A stressoptimized, ductile iron spindle is splined to the rear brakes, reducing brake pack rebuild time by up to two hours. In addition, the spindles are longer and wider with fewer seals for increased strength and durability. Brake Packs. A single-piece brake anchor eliminates more than 200 fasteners and a row of bolted joints....

Open the catalog to page 7

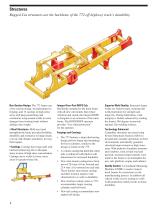

Structures Rugged Cat structures are the backbone of the 772 off-highway truck’s durability. Box-Section Design. The 772 frame uses a box-section design, incorporating two forgings and 13 castings in high-stress areas with deep penetrating and continuous wrap-around welds to resist damage from twisting loads without adding extra weight. • Steel Structures. Mild steel used throughout the frame provides flexibility, durability and resistance to impact loads, even in cold climates and allows for easy field repairs. • Castings. Castings have large radii with internal reinforcing ribs to...

Open the catalog to page 8

Operator’s Station Ergonomically designed for operator comfort, superior control and high productivity. All New Center-Mounted Cab. Center cab positioning provides additional room and creates a walk-in-style cab. The new configuration allows the operator to easily enter and exit the cab. The cab environment offers a spacious surrounding, giving the operator the ability to stretch out and providing superior comfort for an entire operating shift. The operator seat is located on the right hand side of the cab with the trainer to the immediate left. Ergonomic Layout. The 772 operator’s station...

Open the catalog to page 9

Engine – Power Train Integration The system electronically combines critical power train components to work together more intelligently to optimize overall truck performance. Engine Control Module (ECM) Sensors Mechanical Electronic Unit Injector (MEUI) Automatic Retarder Control (ARC) 9 Traction Control System (TCS) Transmission/Chassis Control (TCC) Transmission Wheel Sensor Brakes CAT Data Link Cat Messenger Cat Data Link. Electronically integrates machine computer systems to optimize overall power train performance, increase reliability and component life, and reduce operating costs....

Open the catalog to page 10All Caterpillar Global Mining catalogs and technical brochures

-

D9 DOZER

20 Pages

-

745

28 Pages

-

725C2

28 Pages

-

Cat ® 621K

4 Pages

-

D9T

20 Pages

-

D8T

20 Pages

-

735B Articulated Truck

20 Pages

-

725 Articulated Truck

20 Pages

-

777D

28 Pages

-

775G

32 Pages

-

773E

24 Pages

-

772G

28 Pages

-

770

32 Pages

-

16M

24 Pages

-

14M

28 Pages

-

795F AC

24 Pages

-

793D

32 Pages

-

789D

28 Pages

-

789C

28 Pages

-

HW300

16 Pages

-

785D

24 Pages

-

AEXQ1170 ShovelsBrochure

32 Pages

-

D11T/D11T CD

28 Pages

-

D10T

20 Pages

-

MD6240 Rotary Drill

28 Pages

-

Cat ® Rock Flow System

2 Pages

-

LHD Vehicles Product Line

8 Pages

-

Mining Truck (797F)

28 Pages

-

Motor Grader (16M)

24 Pages

-

Off-Highway Truck (773G)

32 Pages

-

Off-Highway Truck (777G)

36 Pages

-

Open Bowl Scraper (627G)

24 Pages

-

Open Bowl Scraper (627H)

20 Pages

-

Open Bowl Scraper (623H)

20 Pages

-

Open Bowl Scraper (631G)

24 Pages

-

Open Bowl Scraper (621H)

20 Pages

-

Open Bowl Scraper (657G)

24 Pages

-

Longwall Mining Equipment

12 Pages

-

LHD Vehicles

8 Pages

-

CTS Drive Systems

8 Pages

-

Cat® Trucks: The ONE for Mining

28 Pages

-

Belt Systems - Underground

12 Pages

-

Armored Face Conveyors (AFCs)

12 Pages

-

Longwall Automation

12 Pages

-

Cat® track drills MD5150

28 Pages

-

Electric Rope Shovels 7182

3 Pages

-

Cat® track drills MD5125

4 Pages

-

Cat® track drills MD5050 T

4 Pages

-

Cat® track drills MD5090

4 Pages

-

Cat® track drills MD5075

4 Pages

-

Electric Rope Shovels 7295

3 Pages

-

Electric Rope Shovels 7395

3 Pages

-

Cat® track drills MD5050

4 Pages

-

Cat® Rotary drills MD6750

4 Pages

-

Cat® Rotary drills MD6640

4 Pages

-

Electric Rope Shovels 7495

3 Pages

-

Cat® 8750 DRAGLINE RANGE

28 Pages

-

Master Idler

399 Pages

-

Cat® 8200 DRAGLINE RANGE

2 Pages

-

Cat® 8200-127 Dragline

2 Pages

-

Cat® 8200-126 Dragline

2 Pages

-

Cat® 8200-125 Dragline

2 Pages

-

Cat® 8200-124 Dragline

2 Pages

-

Cat® 8200-123 Dragline

2 Pages

-

Cat® 8200-113 Dragline

2 Pages

-

740B EJ articulated track

24 Pages

-

740B articulated track

20 Pages

-

730 ejector articulated track

20 Pages

-

730 articulated track

20 Pages

-

Feeder Breakers

4 Pages

-

Belt Systems & Belt Products

8 Pages

Archived catalogs

-

Draglines

8 Pages

-

988H Wheel Loader

24 Pages

-

844H Wheel Dozer

20 Pages

-

Scoops

8 Pages

-

Face Haulers

12 Pages

-

Continuous Miners

8 Pages

-

Longwall Shearers

16 Pages

-

Roof Support Carriers

12 Pages

-

Roof Support Systems

8 Pages

-

Automated Plow Systems

12 Pages

-

Jumbo Drills

12 Pages

-

Rotary Blasthole Drills

8 Pages

-

Hydraulic Track Drills

8 Pages

-

Hydraulic Shovels

12 Pages

-

Highwall Mining System

8 Pages

-

Electric Rope Shovels

12 Pages

-

Surface Belt Structure

8 Pages