Website:

Caterpillar Equipment

Website:

Caterpillar Equipment

Group: Caterpillar

Catalog excerpts

PL87 Pipelayer Engine Engine Model Net Power – ISO 9249 Net Power – ISO 9249 (Metric) Cat® C15 ACERT™ 273 kW 366 hp 371 hp Weights Operating Weight Lift Capacity Lift Capacity at Tipping Point – ISO 8813 54 485 kg 120,119 lb 97 069 kg 214,000 lb

Open the catalog to page 1

Pipelayer Integrated, robust components Winches New heavy-duty winch design works with updated machine hydraulics for greater productivity. Boom and hook draw works are driven by independent hydraulic winches. Oil-disc brakes provide smooth operation and positive retention of boom and hook positions. A modular, pin-on design allows for fast replacement and easy field service. Interchangeable parts between hook and boom winch assemblies help reduce cost and downtime. The winch profile has been reduced to enhance visibility and meet critical transport requirements for rail shipment....

Open the catalog to page 3

Operator Station Designed for Productive Comfort Caterpillar designs operator stations for maximum productivity. Operator comfort features and excellent visibility all around the machine help operators work more efficiently and contribute to job site safety. Customers may choose an Open Cab (OROPS), an Enclosed Cab with single pane glass, or an Arctic Cab with Dual Pane glass. • A Roll Over Protection Structure (ROPS) provides added operator protection with an open or enclosed cab. • A more durable access ladder design aids access/egress to the operator station, and can be removed to...

Open the catalog to page 4

Implement and Steering Controls Ergonomically Designed for Ease of Operation 2 Pipelayer Control Right joystick places all of the boom, hook and counterweight function control in one hand. Low-effort, ergonomically designed control handle allows simultaneous, precise positioning of the load line and boom. 1) Increment/decrement buttons on pipelayer control handle provide continuous adjustable throttle. 1 3 2) Thumb rocker controls the counterweight functions. 3) Joystick forward lowers the hook and joystick back raises the hook. Joystick left lowers the boom and joystick right raises the...

Open the catalog to page 5

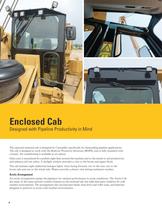

Enclosed Cab Designed with Pipeline Productivity in Mind The optional enclosed cab is designed by Caterpillar specifically for demanding pipeline applications. The cab is designed to work with the Rollover Protective Structure (ROPS), and is fully insulated with a heater. Air conditioning is available as an option. Glass area is maximized for excellent sight lines around the machine and to the trench to aid productivity and enhance job site safety. A skylight window provides a view to the boom and upper block. The cab includes eight additional halogen lights: three facing forward, two to...

Open the catalog to page 6

Engine and Power Train Powerful Efficiency Engine The Cat C15 engine with ACERT™ Technology provides the large displacement and high torque rise for the power needed on challenging jobs. Matched to the high-efficiency torque divider and electronically controlled power shift transmission, the C15 ACERT engine will provide years of dependable service. Constant Net Horsepower Constant net horsepower maintains high standards of performance and response. The engine automatically adjusts to maintain power output and conversely lowers output when demands are low. This provides significant fuel...

Open the catalog to page 7

Structure Underlying Strength The Pipelayer main frame is engineered to handle the most demanding applications. The mainframe is built to absorb high impact shock loads and twisting forces, and full box section frame rails are designed to keep components rigidly aligned. Heavy steel castings add strength to the main case, center saddle and front cross member for outstanding durability. Top and bottom rails are continuous rolled sections, with no machining or welding, to provide superior mainframe durability. The final drives are elevated well above the ground level work area to protect them...

Open the catalog to page 8

Integrated Technologies Solutions to Make Work Easier and More Efficient Cat Product Link* Remote monitoring with Product Link improves overall fleet management effectiveness. Product Link is deeply integrated into machine systems. Events and diagnostic codes, as well as hours, fuel, idle time and other detailed information are transmitted to a secure web based application, VisionLink™. VisionLink includes powerful tools to convey information to users and dealers, including mapping, working and idle time, fuel level and more. *Product Link licensing not available in all areas. Load Monitor...

Open the catalog to page 9

Serviceability More Productivity, Less Cost Grouped service points and easy maintenance contribute to increased machine up-time for greater productivity and reduced costs. Easy Diagnostics The machine monitoring system provides instant feedback on the condition of operating systems, utilizing a three level warning system. The system can easily be upgraded by flashing software. Service Access • For ease of servicing, all regular engine maintenance points are easily reached through the left-hand engine compartment. • Engine doors are equipped with door handles and keyed locks for better...

Open the catalog to page 10

Safety Designed with Protection in Mind Job site safety is a key concern for pipeline customers, and Cat pipelayers are designed with features to help protect people in and around the machine. • A Roll Over Protection Structure (ROPS) provides added operator protection with an open or enclosed cab. • New winch profile and additional mirrors provide even greater visibility around the machine. • Increased undercarriage length and repositioned rear idler enhance slope capability. • PL87 pipelayers are Load Monitor Indicator (LMI) ready to help operators monitor loads for enhanced job site...

Open the catalog to page 11

PL87 Specifications Engine Hydraulic System Cat® C15 ACERT™ U.S. EPA Tier 3, EU Stage IIIA Gross Power 294 kW 394 hp Gross Power (Metric) 400 hp Gross Power – 281 kW 377 hp ISO 14396 Gross Power – 382 hp ISO 14396 (Metric) Flywheel Power 273 kW 366 hp Flywheel Power 371 hp (Metric) Net Power – 273 kW 366 hp ISO 9249 Net Power – 371 hp ISO 9249 (Metric) Net Power – 270 kW 362 hp SAE J1349 Net Power – 367 hp SAE J1349 (Metric) Net Power – 273 kW 366 hp EU 80/1269 Net Power – 371 hp EU 80/1269 (Metric) Bore 137 mm 5.4 in Stroke 172 mm 6.75 in Displacement 15.2 L 928 in3 Engine Model Emissions...

Open the catalog to page 12All Caterpillar Equipment catalogs and technical brochures

-

Cat® 226D3

4 Pages

-

Cat® 8000

2 Pages

-

239D/249D/259D/279D/289D

20 Pages

-

Cat® 279D

4 Pages

-

730C2 EJ Articulated Truck

28 Pages

-

745C Articulated Truck

28 Pages

-

816F Series 2

20 Pages

-

C10302115

2 Pages

-

C10302112

5 Pages

-

Longwall Shearers

16 Pages

-

Intelligent CST Drive System

8 Pages

-

D6N WH Waste Handler

3 Pages

-

D8T Track-Type Tractor

24 Pages

-

D3K Track-Type Tractor

16 Pages

-

963D Track Loader

28 Pages

-

953D Track Loader

28 Pages

-

TL642C Telehandler

2 Pages

-

Engineered Belt Terminal Groups

12 Pages

-

527 Track Skidder

12 Pages

-

RM300 Rotary Mixer

16 Pages

-

PL61 Pipelayer

20 Pages

-

777F Off-Highway Truck

28 Pages

-

770 Off-Highway Truck

32 Pages

-

M313D Wheel Excavator

32 Pages

-

834H Wheel Dozer

20 Pages

-

824H Wheel Dozer

20 Pages

-

814F Series 2 Wheel Dozer

20 Pages

-

973D Track Loader

20 Pages

-

AP500E Asphalt Paver

32 Pages

-

740B EJ Articulated Truck

24 Pages

-

740B Articulated Truck

20 Pages

-

740 Ejector Articulated Truck

20 Pages

-

740 Articulated Truck

20 Pages

-

735B Articulated Truck

20 Pages

-

735 Articulated Truck

20 Pages

-

730 Ejector Articulated Truck

20 Pages

-

730 Articulated Truck

20 Pages

-

420E/420E IT Backhoe Loader

28 Pages

-

Backhoe Loader

20 Pages

-

Articulated Truck

20 Pages

-

Track-Type Tractor

16 Pages

-

Telehandler

2 Pages

-

Track Skidder

5 Pages

-

Skid Steer Loaders

16 Pages

-

Rotary Mixer

16 Pages

-

Asphalt Paver

12 Pages

-

Stationary Mount Loader

8 Pages

-

Wheel Harvesters

4 Pages

-

Forwarder

4 Pages

-

Track Feller Buncher

20 Pages

-

Compactors

20 Pages

-

Cold Planer

16 Pages

Archived catalogs

-

Wheel Excavator

24 Pages

-

Wheel Dozer

20 Pages

-

Off-Highway Truck

32 Pages

-

Motor Grader

20 Pages

-

Mini Hydraulic Excavators

8 Pages

-

Backhoe Loader

20 Pages

-

Pipelayer

20 Pages

-

Articulated Truck

20 Pages