Catalog excerpts

Twin arc wire spraying technology ■ Prolonging the service life of critical components ■ Faster deposition rate ■ Cost effective solution for increasing productivity ■ Safe process, no flammable gases used

Open the catalog to page 1

EuTronic® Arc wire EuTronic® Arc PROCESS Function EuTronic® Arc is the highest productivity thermal spraying process. EuTronic® Arc is an Arc Spray Process using a pair of wires which are melted by an electric arc. The arc has a temperature of 5 000 - 6 000°C that melts the wires continuously. Compressed gas - most often air - is used to atomise the molten wire tips and to propel the droplets towards the substrate at velocities exceeding 100 meters per second. This molten material is atomised by compressed gas and propelled towards the workpiece to form a coating. This combination of high...

Open the catalog to page 2

Eutectic* Castulin EuTronic® Arc Spray Wire RANGE Designations Bond Coat EuTronic® Arc 500 Alloy Ni-AI EuTronic® Arc 502 Alloy Fe-Cr-Ti-Si-Mn EuTronic® Arc 509 Alloy Fe-Cr-Al-Mo Cement cooler plates, boiler water wall protection, pulp production digesters, steam turbine casings, cracking installations, high temperature cyclone, fume extractors etc. Corrosion and erosion resistant protective coatings in boiler equipment up to 900°C. EuTronic® Arc 521 Alloy Zn-Al Protection of iron and steel in urban and rural environment, electro-magnetic screening. Primer for surface which will be painted....

Open the catalog to page 3

EuTronic® Arc wire Arc spray wire production Today the vast majority of wires used for arc wire spraying are solid, extruded wires of standard compositions of zinc and aluminium. By shifting to the more advanced «cored wire», innovation in surface protection is easier to achieve. Cored wires consist of a formal metal strip filled with different powders (metal and mineral). The flexibility in choice of metal and powder compositions, have enabled us to produce wire compositions with new high-tech production equipment that are impossible to produce as solid wires. Such wires have been tuned...

Open the catalog to page 4

Arc Wire spray equipment development Castolin Eutectic have been manufacturing specialist cored wires for nearly 20 years to be used on all standard arc wire equipment available on the market. Usually, the superior quality of the wires outperforms competition wires on these standard arc wire spray equipment. In order to extract the best potential of the wires in terms of coating quality and spraying systems, Castolin Eutectic decided to design and bring to the market dedicated Arc Wire Spray equipment in 2007 which would reliably reproduce the excellent quality of the coatings afforded by...

Open the catalog to page 5

Castolin Eutectic CastoLab® Services Workshops Our mission is to develop applications and solve customer problems. The CastoLab® Services can develop advanced procedures to allow transfer of complete solutions to end users. We offer a complete and comprehensive service for the maintenance of machine parts and major components subject to extensive service wear or needing repair. Work can either be undertaken in our workshops or alternatively on site. Often the parts being repaired or protected need to be produced on a regular basis, and here “specialist prepared parts” can be produced in...

Open the catalog to page 6

History of Castolin Eutectic 1906 Foundation of Castolin Eutectic in Lausanne, Switzerland by 1940 1960 1963 1965 1976 1985 1994 1995 2000 2005 2006 Jean-Pierre Wasserman. His stroke of genius : to discover a low temperature way to weld cast iron. Foundation of Eutectic Welding Alloys Corporation in New York. International consolidation under Castolin Eutectic. Launch of powder spray-fuse Eutalloy® torch for powder spraying with simultaneous fusion. More than 42000 units were sold. Powder production by water atomisation. Powder production by gas atomisation. Marketed the world’s first...

Open the catalog to page 7

Ask for a demonstration from our Application Specialists. -> www.castolin.com <<< -> www.eutectic.com <<< 8 Stronger, with Castolin Eutectic www.castolin.com www.eutectic.com

Open the catalog to page 8All Castolin Eutectic catalogs and technical brochures

-

EutecTrode®

12 Pages

-

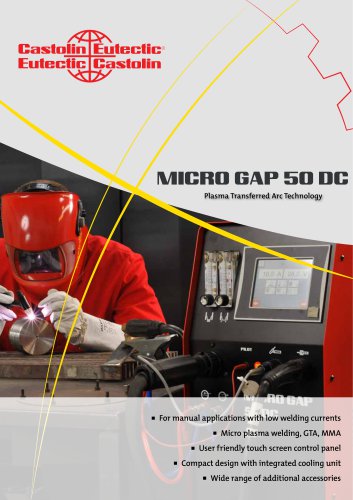

2020 MICRO GAP 50 DC

2 Pages

-

CastoJet® CJK5

2 Pages

-

EuTronic Arc Spray 4 HF

4 Pages

-

EuTronic® Arc 525 AS

2 Pages

-

EuTroLoy PG 6606

2 Pages

-

EuTroLoy 16457

2 Pages

-

EuTroLoy 16365G

2 Pages

-

OTW 10SS

2 Pages

-

TeroMatec

12 Pages

-

DH range

4 Pages

-

CastoDur

12 Pages

-

CastoTubes

4 Pages

-

Eutalloy ® - Eutalloy ® SF

12 Pages

-

TeroCote ®

8 Pages

-

hardbanding_oil_gas_industry

2 Pages

-

DERBY 425 DS II

2 Pages

-

XuperMIG 3000

2 Pages

-

Castolin Eutectic

48 Pages

-

CastoJet ® HVOF Powder

2 Pages

-

EuTronic ® GAP 2501 DC

4 Pages

-

XuperArc 3200 / 4000 / 5000

2 Pages

-

PowerTec

5 Pages

-

GreenBraz-brazing

12 Pages

-

OTW range

8 Pages

-

GlassTec Brochure

4 Pages

-

SteelTec

8 Pages

-

Distribution Catalog

32 Pages

-

CastoLab

12 Pages

-

OilTec

8 Pages

-

Waste and Recycling

8 Pages

-

Steel

8 Pages

-

Mining

12 Pages

-

Cement

8 Pages

-

GoodAire 1202 ®

2 Pages

-

ID WELD 2501

2 Pages

Archived catalogs

-

MICRO GAP 50 DC

4 Pages

-

wear plates

2 Pages

-

GAP

8 Pages

-

CastoDyn SF Lance

2 Pages

-

CastoMIG

12 Pages

-

XuperTIG

8 Pages

-

CastoTIG 2201 DC

2 Pages

-

CastoTIG 1501 DC

2 Pages

-

XuperMax²

2 Pages

-

UltraMax²

2 Pages