Catalog excerpts

High performance Manual Metal Arc electrodes for repair, joining, rebuilding and wearfacing applications Low-heat input welding for safe, reliable repairs Anti-wear protective coatings, for longer-lasting parts Ease of use, even in difficult positions For cost-saving, industrial maintenance solutions

Open the catalog to page 1

EutecTrode® Manual Metal Arc Process Simultaneously the flux coating decomposes into a gas shield and slag to protect the solidifying weld pool from the surrounding atmosphere. After cooling, the When an electric arc is struck between a flux coated electrode and a workpiece, the core wire tip and the workpiece surface melt to form a liquid weld pool. Consumable electrode Flux covering Evolved gas shield Core wire Weld pool Slag Weld metal Parent metal slag cover must be chipped off the weld bead and wire brushed before welding the next electrode. Equipment is simple, inexpensive & often...

Open the catalog to page 2

Wear Analysis The latest state-of-the-art testing machines and facilities are essential to accurately monitor wear phenomena and understand the complex relationship between chemistry, process and application. We work with world experts in Technical Universities for testing and modelling in addition to having fully equipped laboratories with electron microscopes and wear test facilities. Modeling of wear surface Unique wear test machine Scanning Electron Microscope Worn structure EutecTrode® Manufacturing Facilities The EutecTrode® range of high performance electrode formulations are...

Open the catalog to page 3

Crack repairs and joining with Maximum Safety Margin Low heat input for safer welds Our EutecTrode® flux coatings are specially formulated to ensure that the workpiece is heated as little as possible during welding. This reduces many risks such as : weld metal dilution, grain growth, formation of brittle phases, hot Extremely versatile electrode range cracking of the weld, residual stresses, deformation, distortion, undercutting, burn-through and electrode overheating, which can Xuper 680 S weld microstructure with close, interlinking austenite / ferrite grains providing strongest cracking...

Open the catalog to page 4

Low a Hig lloy s te ha Sta lloy els inle ste Cas ss s els te ti Nic rons els kel Cop allo ys pe Alu r allo mi niu ys ma lloy s 2-44 2-44 NC 285 EutecTrode® range for crack repair and joining Technical Data Cold welding of old, oily, contaminated grey cast irons. Non con- Tensile strength Rm: 250-300 ductive version for limited accessibility. Deposits are machinable. N/mm2 Hardness: 100-130 HV30 Welding of tin or phosphor bronzes with low preheat e.g. pump rotors also for dissimilar joining of bronze to steel or cast iron. Tensile strength Rm: 240-300 N/mm2 Hardness: 100-140 HB Tensile...

Open the catalog to page 5

Wearfacing for longer service life Application Engineered coatings EutecTrodes are just one way of applying our renowned TeroCote® anti-wear protective coatings. TeroCote® alloys offer durable protection because each forms a deposit structure which provides optimum resistance against a specific type of wear, or combination of wear phenomena. Extensive research helps us to identify the most appropriate alloy type, size and distribution of complex phas- XHD 6395N microstructure with numerous complex hard phases evenly distributed within a NanoAlloy matrix. This gives optimum protection...

Open the catalog to page 6

Ab ras Ero ion si Cav on it Imp ation a Fric ct tio Cor n ro He sion at EutecTrode® range for anti-wear protective coating Technical Data Cold stamping tools, dies, punches, hammers. Deposits are heat treatable and nitridable. Hardness: 56 - 61 HRC quenched from 950°C: 58-59 HRC Crusher hammers, ripper teeth, grab buckets, drilling equipment where high impact is combined with medium abrasion. Ideal for buttering layers and rebuilding hardenable alloy steel or 13% manganese steel. Deposits rapidly work harden. Hardness: ~170HV after work hardening: ~430 HV30 For abrasion on low alloy and...

Open the catalog to page 7

MMA Equipment To obtain perfect welds, you need not only an excellent electrode but also outstanding equipment quality. Castolin Eutectic has developed for you a complete range of MMA power sources starting from 140 Amps to 650 Amps. This wide range will give you the possibility to use welding for your small applications as well as really tough industrial ones. UltraMax2 Technical data Welding amperage range 35% Duty cycle amperage 100% Duty cycle amperage Open circuit voltage Power supply Power at primary (100%) Fuse rating Protection index Dimensions L x W x H (mm) Weight • For MMA and...

Open the catalog to page 8

CastoLab® Services Our mission is to develop applications and solve customer problems. Depending on the customer’s wish, we can transfer this knowledge to him or perform the work for him in our approved CastoLab® Services workshops. CastoLab® Services can develop advanced procedures to allow transfer of complete solutions to end users. CastoLab® Services offer a complete and comprehensive service for the maintenance of machine parts and major components subject to extensive service wear or needing repair. Work can either be undertaken in the CastoLab® Services or alternatively on site....

Open the catalog to page 9

EutecTrode® Castolin Eutectic To increase customer know-how in wear technology and repair techniques, we have developed a full line of seminars and training programs, teaching all relevant personnel from welders and engineers to sales teams and managing directors. Castolin Eutectic Locations Together with our sister companies in the Messer World, we can offer our customers a very powerful range of products and services. Being Part of the Messer World means: The unique TeroLink® database of Castolin Eutectic contains more than 8,000 fully documented approved applications from around the...

Open the catalog to page 10

History of Castolin Eutectic 1906 Foundation of Castolin in Lausanne, Switzerland by Jean-Pierre Wasserman. His stroke of genius: to discover way of welding cast iron at low temperature. In the following years, this innovation was further developed for all industrial metals including aluminium alloys 1985 RytmArc portable power source First machinable cast iron electrode 1978 Establishment of World Head Quarters in St-Sulpice, Switzerland 1980’s XHD electrode range 1995 Global Stainless Steel electrode range 1948 First arc electrodes for cutting & gouging 1996 First CaviTec alloy electrode...

Open the catalog to page 11All Castolin Eutectic catalogs and technical brochures

-

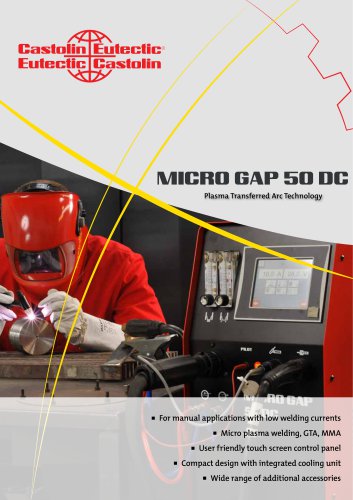

2020 MICRO GAP 50 DC

2 Pages

-

CastoJet® CJK5

2 Pages

-

EuTronic Arc Spray 4 HF

4 Pages

-

EuTronic® Arc Spray Wires

8 Pages

-

EuTronic® Arc 525 AS

2 Pages

-

EuTroLoy PG 6606

2 Pages

-

EuTroLoy 16457

2 Pages

-

EuTroLoy 16365G

2 Pages

-

OTW 10SS

2 Pages

-

TeroMatec

12 Pages

-

DH range

4 Pages

-

CastoDur

12 Pages

-

CastoTubes

4 Pages

-

Eutalloy ® - Eutalloy ® SF

12 Pages

-

TeroCote ®

8 Pages

-

hardbanding_oil_gas_industry

2 Pages

-

DERBY 425 DS II

2 Pages

-

XuperMIG 3000

2 Pages

-

Castolin Eutectic

48 Pages

-

CastoJet ® HVOF Powder

2 Pages

-

EuTronic ® GAP 2501 DC

4 Pages

-

XuperArc 3200 / 4000 / 5000

2 Pages

-

PowerTec

5 Pages

-

GreenBraz-brazing

12 Pages

-

OTW range

8 Pages

-

GlassTec Brochure

4 Pages

-

SteelTec

8 Pages

-

Distribution Catalog

32 Pages

-

CastoLab

12 Pages

-

OilTec

8 Pages

-

Waste and Recycling

8 Pages

-

Steel

8 Pages

-

Mining

12 Pages

-

Cement

8 Pages

-

GoodAire 1202 ®

2 Pages

-

ID WELD 2501

2 Pages

Archived catalogs

-

MICRO GAP 50 DC

4 Pages

-

wear plates

2 Pages

-

GAP

8 Pages

-

CastoDyn SF Lance

2 Pages

-

CastoMIG

12 Pages

-

XuperTIG

8 Pages

-

CastoTIG 2201 DC

2 Pages

-

CastoTIG 1501 DC

2 Pages

-

XuperMax²

2 Pages

-

UltraMax²

2 Pages