Catalog excerpts

Prodotto in ACCIAIO AL CARBONIO e in ACCIAIO INOssidabile AVAILABLE IN CARBON AND STAINLESS STEEL

Open the catalog to page 1

FIGURATIVE INDEX – FITTINGS SAE J514 - ISO 8434-2 General instructions Quality assurance Allowed temperatures Finish treatments Threaded ends Prescriptions to comply with Utilisation standards Safety factors Assembly instructions Type: 2003...3 BSPP Type: 2005...3 UNF/UN-2A Type: 2004...3 Metric paral. Type: 2010...3 BSPT Type: 2011...3 NPTF Type: 2012...3 BSPT Type: 2013...3 NPTF Type: 2014...3 BSPT Type: 2015...3 NPTF Type: 2016...3 BSPT Type: 2017...3 NPTF Type: 2008...3 BSPT Type: 2009...3 NPTF Type: 2035.. BSPP Type: 2036.. Metric paral. Type: 2038.. BSPT Type: 2039.. NPTF Type:...

Open the catalog to page 2

ATTREZZATURE SERIE SAE J514 - ISO 8434-2 TUBE FLARING MACHINE Ordering Machine Ordering 37° flaring block Ordering metric Ordering inches

Open the catalog to page 3

ORDERING EXAMPLES (Carbon steel) ORDERING EXAMPLES (Stainless steel) • If you require a male stud coupling for a Ø 20 mm tube with 3/4” BSP parallel thread made of carbon steel with elastomeric NBR seal on the thread, order 200306.3 • If you require the VITON® seal, add “V” at the end. Material carbon steel Male stud coupling BSP parallel thread Ø 20 mm tube 3/4” BSP parallel thread • If you require a male stud coupling for a Ø 20 mm tube with 3/4” BSP parallel thread made of stainless steel with elastomeric VITON® seal on the thread, order 210306.3 Material stainless steel Male stud...

Open the catalog to page 4

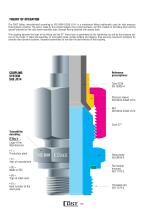

THEORY OF OPERATION The CAST fitting, manufactured according to ISO 8434-2/SAE J514, is a mechanical fitting traditionally used for high pressure fluid-dynamic systems. The seal is made by the contact between two conical surfaces, the first created on the fitting body and the second obtained on the cold drawn seamless tube, through flaring obtained with special tools. The coupling between the body of the fitting and the 37° flared tube is guaranteed by the tightening nut and by the pressure sleeve on the inside. It helps fast assembly of removable tubes, avoids welding and tapping, thus...

Open the catalog to page 5

TECHNICAL CHARACTERISTICS CAST 37° fittings assure perfect seal regardless of the fluid used, provided that no corrosive fluids are employed, the nominal pressures of the fittings and the indicated temperatures are respected and the prescriptions of the manufacturer are followed scrupulously. These fittings are manufactured in a single series defined “UNIVERSAL” since the fitting body and the tightening nut remain the same also when switching from a metric tube at an inches sized tube. There are no doubles of diameters with different working pressures. Normal vibrations do not alter the...

Open the catalog to page 6

PRODUCT MATURITY For many years now there has been an increasing imperative market demand for fluid system components that guarantee three main factors: SAFE ANCHORING, FUNCTIONAL ASSEMBLY, LEAKAGE-FREE TIGHTNESS. These elements, now considered essential for a safe working environment (Leg. Decree 81/2008), product liability (Presidential Decree 224-EEC 85/374) and for the entire environmental protection system, make the 37° fitting manufactured by CAST S.p.A. a reliable and consolidated product. GENERAL INSTRUCTIONS • Before starting to flare the tubes, please check that all the tools to...

Open the catalog to page 7

0 Metric 0 Inch fl0 FlaringA _ Blocking tube tube min max C The values in the tightening tables are approximate and derive from practical tests run at the laboratory in Casalgrasso (CN), which may vary based on the materials and tolerances of the components used. Thus an awareness of the controls to be performed is required. All the values expressed in Newton Meters (Nm) for the tightening torques tube side on the SAE J514 cone represent the tor-quing moment, calculated on the maximum thickness of the usable tube, needed to obtain the correct tightness. All the values expressed in...

Open the catalog to page 8

ASSEMBLY INSTRUCTIONS SAE J514 1. Before starting the 37° tube flaring and assembly operations, please check that all the tools to be used are in perfect working order. Substitute those not complying to the requirements. 2. Cut the tube square by using an appropriate hack-saw (do not use roller type tube cutters). Check that the cut is properly made at 90°. Remove any internal and external burrs. 3. Check for any leakage line and other structural defects that may impair the seal on the cone of the fitting body. Reject any non complying tube. 4. Thoroughly clean the part of the tube to be...

Open the catalog to page 9