Catalog excerpts

Prodotto in ACCIAIO AL CARBONIO e in ACCIAIO INOssidabile AVAILABLE IN CARBON AND STAINLESS STEEL

Open the catalog to page 1

FIGURATIVE INDEX – FITTINGS SAE J1453 - ISO 8434-3 General instructions Quality assurance Allowed temperatures Finish treatments Threaded ends Prescriptions to comply with Utilisation standards Safety factors Assembly instructions Type: 4004.. BSPP Type: 4005.. Metric paral. Type: 4007.. BSPP Type: 4008.. Metric paral. Type: 4022.. BSPP Type: 4024.. BSPP Type: 4023.. Metric paral. Type: 4025.. Metric paral. Type: 4027.. ORFS/DIN gir. Type: 4028...3 ORFS/JIC Type: 4029.. ORFS/JIC gir. Type: 4030...3 ORFS gir. JIC Type: 4031.. ORFS/BSI Type: 4032.. ORFS gir. BSI Type: 4033.. BSPP Type: 4035.....

Open the catalog to page 2

ORDERING EXAMPLES (Carbon steel) ORDERING EXAMPLES (Stainless steel) ORFS • If you require a male stud coupling for a Ø 20 mm tube with 3/4” BSP parallel thread made of carbon steel with elastomeric NBR seal on the threaded end, order: 400405 • If you require the VITON® seal, add “V” at the end. Series SAE J1453 Material carbon steel Male stud coupling BSP parallel thread Ø 20 mm tube 3/4” BSP parallel thread ORFS • If you require a male stud coupling for a Ø 20 mm tube with 3/4” BSP parallel thread made of stainless steel with elastomeric VITON® seal on the threaded end, order: 410405 • If...

Open the catalog to page 3

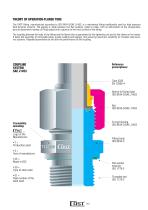

THEORY OF OPERATION-FLARED TUBE The CAST fitting, manufactured according to ISO 8434-3/SAE J1453, is a mechanical fitting traditionally used for high pressure fluid-dynamic systems. The sealing is made between two flat surfaces, metal to metal, with no deformation of the components, plus an elastomeric sealing (O-Ring) placed into a groove on the front surface of the fitting. The coupling between the body of the fitting and the flared tube is guaranteed by the tightening nut and by the sleeve on the inside. It helps fast assembly of removable tubes, avoids welding and tapping, thus assuring...

Open the catalog to page 4

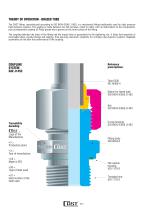

THEORY OF OPERATION - BRAZED TUBE The CAST fitting, manufactured according to ISO 8434-3/SAE J1453, is a mechanical fitting traditionally used for high pressure fluid-dynamic systems. The sealing is made between two flat surfaces, metal to metal, with no deformation of the components, plus an elastomeric sealing (O-Ring) placed into a groove on the front surface of the fitting. The coupling between the body of the fitting and the brazed tube is guaranteed by the tightening nut. It helps fast assembly of removable tubes, avoids flarings and tapping, thus assuring maximum simplicity for...

Open the catalog to page 5

TECHNICAL CHARACTERISTICS - FLARED TUBE The CAST ORFS fittings assure perfect seal regardless of the fluid used, provided that no corrosive fluids be employed, the nominal pressures of the fittings and the indicated temperatures be respected and the prescriptions of the manufacturer be followed scrupulously. These fittings are manufactured in a single series defined “UNIVERSAL” since the fitting body and the tightening nut remain the same also when switching from a metric tube at an inches sized tube. There are no doubles of diameters with different working pressures. Normal vibrations do...

Open the catalog to page 6

SEALING The new ORFS fitting solves the total sealing problem in the following way: • On the front side of the fitting a groove was created to insert an O-ring. This elastomeric seal guarantees a perfect seal at all times, as dry as dust. • The particular shape of the groove, according to the new prescriptions of standards ISO 8434-3 and SAE J1453, guarantees the containment of the O-Ring inside its groove without the assistance of adhesives. • The presence of the O-Ring groove improves the sealing metal to metal characteristics, since the groove divides the front seal surface of the...

Open the catalog to page 7

ASSEMBLY INSTRUCTIONS ACCORDING TO SAE J1453 FOR FLARED TUBES 1. Before starting the tube flaring and assembly operations, please check that all the tools to be used are in perfect working order. Substitute those not complying to the requirements. 2. Cut the tube square by using an appropriate hack-saw (do not use roller type tube cutters). Check that the cut is properly made at 90°. Remove any internal and external burrs with the suitable deburring tool. 3. To obtain the desired length of the tube please add the L1 quote to the desired length of the tube in the table on page 218. 4. Check...

Open the catalog to page 8

ASSEMBLY INSTRUCTIONS ACCORDING TO SAE J1453 FOR BRAZED TUBES 1. Before starting the tube brazing and assembly operations, please check that all the tools to be used are in perfect working order. Substitute those not complying to the requirements. 2. Cut the tube square by using an appropriate hack-saw (do not use roller type tube cutters). Check that the cut is properly made at 90°. Remove any internal and external burrs with the suitable deburring tool. 3. To obtain the desired length of the tube please subtract the L2 quote from the desired length of the tube in the table on page 218. 4....

Open the catalog to page 9

Metric Inches Metric Inches FUNCTIONALITY • The correct execution of the flaring and brazing is an essential condition for the functionality of the seal of the coupling. • It is necessary to be aware of the importance of preparing the tubes, and total precision in the process is required. • The quality of the processed tubes is a guarantee of safe functionality, easy assembly and a system created simply with an excellent yield.

Open the catalog to page 10

TIGHTENING TORQUES FOR STAPLED SEAM ENDS ASSEMBLY INSTRUCTIONS FOR FITTINGS WITH SWIVEL NUT 1. Before the assembly, check for the correct parameters of all the tools to be used and substitute those not complying to the requirements. 2. Clean the nut, fitting and tube and lubricate with the suggested products. 3. Check the correct alignment of the parts involved, then using a wrench tighten the stapled nut until reaching the contact of the seal surfaces and tighten according to the values of the table. 4. Repeated assembly and disassembly will not alter the functionality of the system which,...

Open the catalog to page 11