Catalog excerpts

COMMERCIAL TECHNICAL CATALOGUE S.p.A.

Open the catalog to page 1

t u ra l a na n and ildre A tion r ch p e ra r ou l c oo v e fo l reser in fu to p ish we w h whi c lon

Open the catalog to page 2

TURIN Mole

Open the catalog to page 3

FOR A CONSTANT IMPROVEMENT The staff concerned full time in the Quality and Research is highly competent and constantly brought up to date and represents the 10% of the employees working with our company. Since 1993 our manual and quality procedures constantly follow the reference rules development. The numerous inspections carried out by the certification agencies have always confirmed the continuous adjustment to the ISO 9001 norm requirements and the steadfast improvement of our quality system. 4

Open the catalog to page 4

Maximum safety is achieved by adopting international regulations for the production of standard fittings. We are obviously also committed to new products, new solutions and new applications to improve the existing technology with process and product innovations, as clearly shown below: 1. Increasing the working pressure of DIN 2353 carbon steel pipe fittings, pages 40 to 92; 2. New ecological zinc-plating process with increased resistance to corrosion, page 24; 3. New dust and processing residue anti-pollution process, page 24; 4. New "compact swivel elbow terminal", pages 48 - 49; 5. New...

Open the catalog to page 5

“PRODUCT RANGE” RESEARCH QUALITY SAFETY DEVELOPMENT RELIABILITY 6

Open the catalog to page 6

APPLICATION FIELDS

Open the catalog to page 7

VOLPIANO OFFICE BUILDING (TO) Headquarters of CAST S.p.A.

Open the catalog to page 8

CARBON STEEL AND STAINLESS STEEL PRODUCT

Open the catalog to page 9

FIGURATIVE INDEX – FITTINGS DIN 2353 – ISO 8434-1 General instructions Quality assurance Allowed temperatures Finish treatments Threaded ends Prescriptions to comply with Utilisation standards Safety factors Assembly instructions Type: 1015.. BSPP Type: 1013.. BSPP Type: 1014.. Metric Paral. Type: 1016.. Page 25-26 Type: 1003.. BSPP Type: 1004.. Metric Paral. Type: 1005.. BSPP Type: 1007.. BSPP Type: 1006.. Metric Paral. Type: 1008.. Metric Paral. Type: 1017.. BSPT Type: 1018.. NPT Type: 1019.. Metric Taper Type: 1021.. NPT Type: 1022.. Metric Taper Type: 1025.. BSPT Type: 1026.. NPT Type:...

Open the catalog to page 10

FIGURATIVE INDEX – FITTINGS DIN 2353 – ISO 8434-1 Type: 6043.. BSPP Type: 6044.. Metric Paral. Type: 6047.. BSPP Type: 6048.. Metric Paral. Type: 6051.. BSPP Type: 6053.. . Type: 6052.. Metric Paral. Type: 5002.. BSPP Type: 5004.. BSPP Type: 5003.. Metric Paral. Type: 5005.. Metric Paral. Type: 5006.. BSPT Type: 5007.. NPT Type: 5008.. BSPT Type: 5009.. NPT Compatible fluids table Page 352-356 ASSEMBLY TOOLS DIN 2353 - ISO 8434-1 PREASSEMBLY MACHINE Ordering Machine MANDREL MACHINE PLATFORM MACHINE MANUAL PREASSEMBLY TOOL Ordering Mandrel Ordering Platform Ordering Preassembly

Open the catalog to page 11

ORDERING EXAMPLES (Carbon steel) ORDERING EXAMPLES (Stainless steel) 1 Standard Ring • If you require a male stud coupling for a Ø 18 mm tube with 1/2” BSP parallel thread made of carbon steel with standard ring, order: 100309 Standard Lo B3tato dell’Arte for a Ø 18 S you require aRing stud coupling • If male mm tube with 1/2” BSP parallel thread made of stainless steel with standard ring, order: 110309 Material carbon steel Male stud coupling BSP parallel thread Ø 18 mm tube 1/2” BSP parallel thread Patented Ring • If you require a male stud coupling for a Ø 18 mm tube with 1/2” BSP...

Open the catalog to page 12

Prodotto in ACCIAIO AL CARBONIO CARBON STEEL AND STAINLESS STEEL PRODUCT STANDARD DOUBLE CUTTING EDGE RING ASSEMBLED ON e in ACCIAIO INOssidabile ALL CAST PRODUCTION TO ASSURE SEALING AND SAFETY. AVAILABLE IN CARBON AND STAINLESS STEEL

Open the catalog to page 13

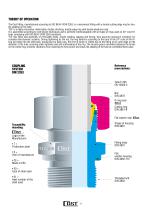

THEORY OF OPERATION The Cast fitting, manufactured according to ISO 8434-1/DIN 2353, is a mechanical fitting with a double cutting edge ring for double stapling on the tube. The B3 ring helps fast assembly of removable tubes, avoids welding, tapping and flaring, thus assuring maximum simplicity for complex oleo-dynamic systems. During tightening by the nut, the ring deforms according to the bore of the 24° cone of the fitting and bites into the steel tube, producing two deep cuts, the first of which is visible due to the lifting of an outer edge on the diameter of the tube, ensuring water...

Open the catalog to page 14

TECHNICAL CHARACTERISTICS CAST fittings assure perfect seal regardless of the fluid used, provided that no corrosive fluids are employed and the nominal pressures be respected. Fittings are manufactured in three ranges to be chosen according to the required working conditions. The “LL” extra light range, suitable for low and medium working pressures up to 100 bars. The “L” light duty series for applications characterised by medium high pressures of maximum 500 bars. The “S” heavy duty series for harsh applications characterised by high temperatures and a maximum pressure of 800 bars. Normal...

Open the catalog to page 15

NEW SIX-SEALS CUTTING RING. THE INTERNATIONAL INDUSTRIAL PATENT NR. 864061 OF 10/03/99 COMPLEMENTS AND DOES NOT REPLACE THE STANDARD RING CURRENTLY IN USE. AVAILABLE IN CARBON AND STAINLESS STEEL

Open the catalog to page 16

THEORY OF OPERATION The Cast fitting, manufactured according to ISO 8434-1/DIN 2353, is a mechanical fitting with a double cutting edge ring for double stapling on the tube. “B4” is a highly innovative, deformable, double clinching, double edge ring with double elastomer seal. It is assembled according to well-known techniques and is perfectly interchangeable with all types of rings used on 24° cone fittings complying with ISO 8434-1/DIN 2353 standards. The ring helps fast assembly of removable tubes, avoids welding, tapping and flaring, thus assuring maximum simplicity for complex...

Open the catalog to page 17

TECHNICAL CHARACTERISTICS The “B4” ring assures perfect tightness of the circuit regardless of the fluid used, provided that corrosive fluids are avoided and the nominal pressures of the fittings are complied with. The fittings on which the “B4” rings are mounted are manufactured in two series, which are used according to the operating conditions. The “L” light duty series for applications characterised by medium high pressures of maximum 500 bars. The “S” heavy duty series for harsh applications characterised by high temperatures and a maximum pressure of 800 bars. Normal vibrations do not...

Open the catalog to page 18