Catalog excerpts

CARBON STEEL AND STAINLESS STEEL PRODUCT

Open the catalog to page 1

FIGURATIVE INDEX – FITTINGS DIN 2353 – ISO 8434-1 General instructions Quality assurance Allowed temperatures Finish treatments Threaded ends Prescriptions to comply with Utilisation standards Safety factors Assembly instructions Type: 1015.. BSPP Type: 1013.. BSPP Type: 1014.. Metric Paral. Type: 1016.. Page 25-26 Type: 1003.. BSPP Type: 1004.. Metric Paral. Type: 1005.. BSPP Type: 1007.. BSPP Type: 1006.. Metric Paral. Type: 1008.. Metric Paral. Type: 1017.. BSPT Type: 1018.. NPT Type: 1019.. Metric Taper Type: 1021.. NPT Type: 1022.. Metric Taper Type: 1025.. BSPT Type: 1026.. NPT Type:...

Open the catalog to page 2

FIGURATIVE INDEX – FITTINGS DIN 2353 – ISO 8434-1 Type: 6043.. BSPP Type: 6044.. Metric Paral. Type: 6047.. BSPP Type: 6048.. Metric Paral. Type: 6051.. BSPP Type: 6053.. . Type: 6052.. Metric Paral. Type: 5002.. BSPP Type: 5004.. BSPP Type: 5003.. Metric Paral. Type: 5005.. Metric Paral. Type: 5006.. BSPT Type: 5007.. NPT Type: 5008.. BSPT Type: 5009.. NPT Compatible fluids table Page 352-356 ASSEMBLY TOOLS DIN 2353 - ISO 8434-1 PREASSEMBLY MACHINE Ordering Machine MANDREL MACHINE PLATFORM MACHINE MANUAL PREASSEMBLY TOOL Ordering Mandrel Ordering Platform Ordering Preassembly

Open the catalog to page 3

ORDERING EXAMPLES (Carbon steel) ORDERING EXAMPLES (Stainless steel) 1 Standard Ring • If you require a male stud coupling for a Ø 18 mm tube with 1/2” BSP parallel thread made of carbon steel with standard ring, order: 100309 Standard Lo B3tato dell’Arte for a Ø 18 S you require aRing stud coupling • If male mm tube with 1/2” BSP parallel thread made of stainless steel with standard ring, order: 110309 Material carbon steel Male stud coupling BSP parallel thread Ø 18 mm tube 1/2” BSP parallel thread Patented Ring • If you require a male stud coupling for a Ø 18 mm tube with 1/2” BSP...

Open the catalog to page 4

Prodotto in ACCIAIO AL CARBONIO CARBON STEEL AND STAINLESS STEEL PRODUCT STANDARD DOUBLE CUTTING EDGE RING ASSEMBLED ON e in ACCIAIO INOssidabile ALL CAST PRODUCTION TO ASSURE SEALING AND SAFETY. AVAILABLE IN CARBON AND STAINLESS STEEL

Open the catalog to page 5

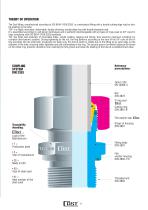

THEORY OF OPERATION The Cast fitting, manufactured according to ISO 8434-1/DIN 2353, is a mechanical fitting with a double cutting edge ring for double stapling on the tube. The B3 ring helps fast assembly of removable tubes, avoids welding, tapping and flaring, thus assuring maximum simplicity for complex oleo-dynamic systems. During tightening by the nut, the ring deforms according to the bore of the 24° cone of the fitting and bites into the steel tube, producing two deep cuts, the first of which is visible due to the lifting of an outer edge on the diameter of the tube, ensuring water...

Open the catalog to page 6

TECHNICAL CHARACTERISTICS CAST fittings assure perfect seal regardless of the fluid used, provided that no corrosive fluids are employed and the nominal pressures be respected. Fittings are manufactured in three ranges to be chosen according to the required working conditions. The “LL” extra light range, suitable for low and medium working pressures up to 100 bars. The “L” light duty series for applications characterised by medium high pressures of maximum 500 bars. The “S” heavy duty series for harsh applications characterised by high temperatures and a maximum pressure of 800 bars. Normal...

Open the catalog to page 7

NEW SIX-SEALS CUTTING RING. THE INTERNATIONAL INDUSTRIAL PATENT NR. 864061 OF 10/03/99 COMPLEMENTS AND DOES NOT REPLACE THE STANDARD RING CURRENTLY IN USE. AVAILABLE IN CARBON AND STAINLESS STEEL

Open the catalog to page 8

THEORY OF OPERATION The Cast fitting, manufactured according to ISO 8434-1/DIN 2353, is a mechanical fitting with a double cutting edge ring for double stapling on the tube. “B4” is a highly innovative, deformable, double clinching, double edge ring with double elastomer seal. It is assembled according to well-known techniques and is perfectly interchangeable with all types of rings used on 24° cone fittings complying with ISO 8434-1/DIN 2353 standards. The ring helps fast assembly of removable tubes, avoids welding, tapping and flaring, thus assuring maximum simplicity for complex...

Open the catalog to page 9

TECHNICAL CHARACTERISTICS The “B4” ring assures perfect tightness of the circuit regardless of the fluid used, provided that corrosive fluids are avoided and the nominal pressures of the fittings are complied with. The fittings on which the “B4” rings are mounted are manufactured in two series, which are used according to the operating conditions. The “L” light duty series for applications characterised by medium high pressures of maximum 500 bars. The “S” heavy duty series for harsh applications characterised by high temperatures and a maximum pressure of 800 bars. Normal vibrations do not...

Open the catalog to page 10

TECHNICAL INNOVATION For many years now there has been an increasing imperative market demand for fluid system components that guarantee three main factors: SAFETY, EASY ASSEMBLY, LEAKAGE-FREE TIGHTNESS. These elements, now considered essential for a safe working environment (Law 626/94), product liability (Presidential Decree 224-EEC 85/374) and for the entire environmental protection system, have promoted the development of the new “B4” ring as an effective response to all the above-mentioned problems. PRODUCT CONCEPT The most original aspect of the product is that the structure of the...

Open the catalog to page 11

DEFINITION OF CONE SIZE TO DIN 3861 STANDARDS THREAD DIAMETERS TO DIN 3853 STANDARDS Allowed for B3-B4-BP rings

Open the catalog to page 12

GENERAL INSTRUCTIONS FOR B3 - B4 - BP RINGS • Before starting the preassembly make sure that the pierce of the machine and the hardened blocks are in perfect working order. Further inspections are necessary during the preassembly (every 30-50 tightenings). For this purpose we recommend you to use a control buffer 1000… pierce and replace any block out of tolerance. • Over the whole tightening phase the tube must be in touch with the inner part of the body of the fitting. If this does not happen, the ring will advance with the tube without indenting it, making the coupling not functional and...

Open the catalog to page 13