Catalog excerpts

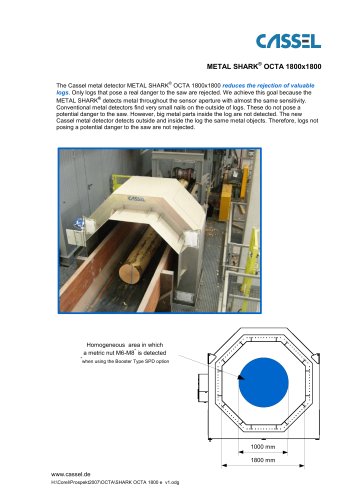

Cassel Messtechnik GmbH 12/06/07 Wood Industry Saves Money due to New Cassel Metal Detector New Metal Detector Protects Machinery and Reduces Rejection of Valuable Logs Dransfeld — 12/06/07 — Wood industry has been spoilt for choice: Either it has protected machinery while rejecting valuable logs or has had to accept excessive downtime. Cassel Messtechnik GmbH puts an end to this with its new metal detector: METAL SHARK® OCTA SPD. Conventional metal detectors can not find metal parts of the same size throughout the log. Example: When set up to find a bombshell inside a log, the metal detector would find tiny nails on the outside of another log which do not pose a danger to a saw or a knife. So, actually, the log could be processed. When adjusted not to find these tiny nails, however, conventional metal detectors do not find dangerous metal parts inside the log that do cause damage. Therefore, one is spoilt for choice: Either one protects machinery while rejecting valuable logs or one has excessive downtime. The new Cassel metal detector is different. It detects outside and inside the log metal objects of similar size. When you set it up to detect a bombshell, it detects a bombshell. Tiny nails are not detected. This way, only logs posing a real danger to the machinery are rejected. The forest industry saves money because it processes and sells all valuable logs, decreases sharpening costs and reduces downtime to a minimum. “One hour of downtime costs at least 5,000 euros,” the technical manager of a big German panel board factory knows. When being asked how valuable a Cassel metal detector is he answers: “We could not run our OSB production line without the Cassel METAL SHARK®.” The standard size of the METAL SHARK® OCTA SPD is 1800x1800. It can be supplied in other sizes and with additional options like a Xenon warning flash lamp or an acoustic alarm. It is specially constructed for rough environment of the forest industry. The METAL SHARK® OCTA SPD 1800x1800 has a homogeneous area of 1000 mm in the center of its aperture. There it can find metal pieces the size of a metric nut M6-M8. The sensor field is more than tenfold stronger than that of conventional metal detectors. Hence, interference from other machinery is strongly reduced. The metal detector comes with a control unit featuring the newest digital technology. This is very easy to handle. One can say that the service technician is already included. “Once set up, the metal detector has run for three years now not having to be adjusted again,” the technical manager, quoted above, explains. About Cassel Messtechnik Cassel Messtechnik GmbH founded in 1994 is a leading manufacturer of metal detectors for industrial purposes. It has a tight network of more than 50 distributors all over the world. Cassel's mission statement is best price, best product, best service. For more information on this and other products you can refer to the website or contact the Cassel staff: Cassel Messtechnik GmbH In der Dehne 10 37127 Dransfeld Phone: +49 5 50 29 11 50 Fax: +49 55 02 91 15 32 E-Mail: info@cassel.de

Open the catalog to page 1

Web: http://www.industrial-metal-detector.com For more information, press only: Hendrik Henze Phone: +49 55 02 91 15 75 E-Mail: hendrik.henze@cassel.de For more information on product: http://www.industrial-metal-detector.com/wood

Open the catalog to page 2All Cassel Messtechnik catalogs and technical brochures

-

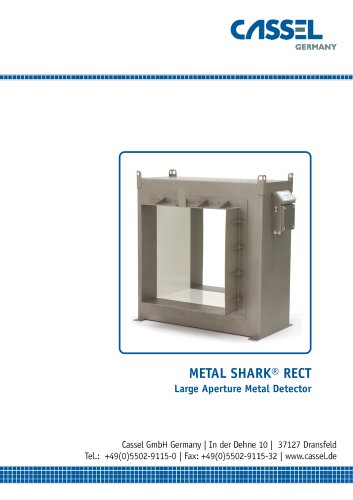

SHARK® RECT

2 Pages

-

SHARK® COMBI-TU

1 Pages

Archived catalogs

-

SHARKNET Software Catalogue

1 Pages

-

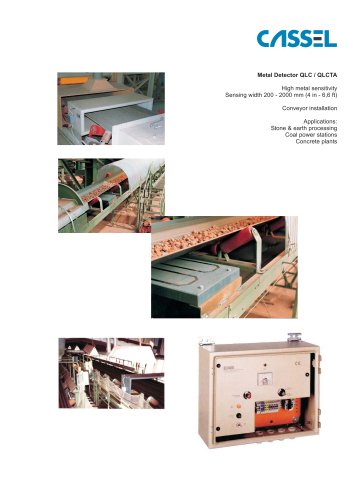

QLC/QLCTA Product Catalogue

2 Pages

-

All METAL SHARK Products

24 Pages