Website:

Carlyle Compressors

Website:

Carlyle Compressors

Catalog excerpts

Compressor Seems Excessively Noisy At Start-up (High Pitch) I Insure oil feed lines are open (oil solenoid). I Check oil pressure at compressor manifold with a gauge. Compressor Makes a Loud Grinding Noise at Start-up I Oil solenoid is leaking oil into the compressor while off. Repair or replace oil solenoid. I Compressor filling with refrigerant while off. Determine refrigerant source and eliminate during compressor off cycle. I Check evaporator superheat. Suction Access Port Min Pressure 10” vacuum Unloading Valve Energize coil to load compressor Suction Service Valve Max temp 65F, 6” from the service valve Motor Temperature (5K thermistor connection on terminal plate) Economizer/ Subcooler Port (not shown) Rotalock valve, 7/8” sweat connection must have 15F - 20F superheat Discharge Service Valve Max Temp 230F, 6” from the service valve (5K thermistor strapped to discharge line) Screw Compressor Troubleshooting Guide Oil Port Access Port (1/4” Schrader, not shown) Liquid For field gauge connections Injection Port Oil Press Transducer (3/8” Flare, Max Press Differential used if necessary) (discharge - oil) 50psi VI (Volume Index) Valve energize coil at Oil Inlet Min Differential Pressure (Oil - Suction) 45psi pressure ratios > 5:1 (3/8” Flare) Discharge Access Port Max Press Differential (discharge - suction) 350psid Compressor Periodically Makes Loud Noise or Becomes Very Quiet for a Short Time Caution: Never Run the Compressor in Reverse! 06T Model I Check for excessive liquid/oil return to compressor. Support/Contact I Call Application Engineering for further assistance at 800.532.5036. Carlyle Compressor Division P. O. Box 4808 Syracuse, NY 13221 Phone: 800.532.5036 Fax: 315.432.3274 0604

Open the catalog to page 1

Reverse Rotation Trips At initial start-up: I Compressor is running in reverse, check phase sequence and bump compressor to insure proper rotation (check pressure at outlet port). I Insure LonCEM module and discharge pressure transducer are wired and functioning correctly. Thermal Protection (High Motor Temperature) Trips I Check economizer rotalock valve to insure it is open. I Check superheat from economizer expansion valve. I Check motor cooling valve for operation to insure liquid is feeding. I Verify motor cooling valve is downstream of check valve. I Verify motor thermistor wiring...

Open the catalog to page 2All Carlyle Compressors catalogs and technical brochures

-

06T Performance DATA

101 Pages

-

05 T Performance DATA

101 Pages

-

Poster

1 Pages

-

5F/H Open-Drive Compressors

4 Pages

-

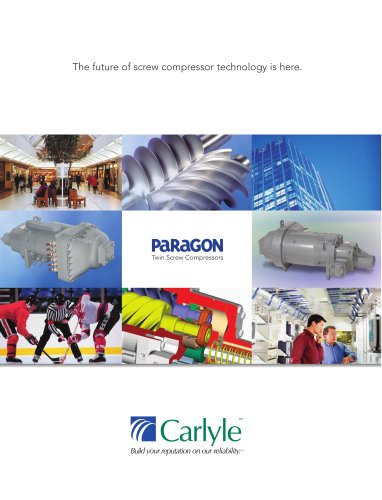

Paragon Compressors

8 Pages