Catalog excerpts

Container securing systems Product catalogue Container securing systems

Open the catalog to page 1

Edition 201202, December 2012 For the latest information, please visit our website www.cargotec.com Contacts: Cargotec Finland Oy Hallimestarinkatu 6 FI-20780 Kaarina, Finland Tel: +358-2-41211 Fax: +358-2-4121 256 Cargotec Marine GmbH Reichsbahnstrasse 72 DE-22525 Hamburg, Germany Tel: +49-40-25 444 0 Fax: +49-40-25 444 444 Cargotec CHS Asia Pacific Pte Ltd No. 15, Tukang Innovation Drive Singapore 618299 Tel: +65-6597 3888 Fax: +65-6597 3799 Distributor for United States, Canada and Mexico: Buffers USA Inc 10180 New Berlin Road Jacksonville, FL 32226 USA Tel: +1-904-696-0010 Email:...

Open the catalog to page 3

Pictures: Arthur Lu, Frank Knöller, Clivia Bergmann, Jukka Rastas/Kuvakasvot, Cargotec archives 4

Open the catalog to page 4

The birth of a ship The design criteria for a feeder vessel’s container stowage solution differ completely from the criteria for an ultra large container carrier, and so do their container securing systems. Whatever the size of the vessel, Cargotec knows how to design and deliver an efficient cargo handling and stowage system for containerised cargo. We know how to get all the parts of this system to work in unison, ensuring that your vessel sails with the best possible performance. A vessel designed for its cargo Building a new vessel is a major investment and the decisions taken at the...

Open the catalog to page 7

Container stowage solutions

Open the catalog to page 8

The best container stowage solutions are built around their intended cargo All elements of the container stowage solution influence each other; understanding all these elements is necessary to define critical areas and find the best possible solutions. An efficient container stowage solution can only be achieved by treating the ship’s hull and its cargo handling system as a single optimised entity, not as separate blocks. Consequently, parts of the container stowage system, such as the hatch covers, lashing bridges, container stanchions, loose and fixed container fittings on deck and in the...

Open the catalog to page 9

Container lashings from drawing board to operation Why should we know about your cargo profile? One of the cornerstones of the way we work is to improve the productivity of our customers’ cargo handling systems, helping them to increase both their competitiveness and their environmental efficiency. With the right indicators, which lead to the right design parameters for your vessel and its cargo handling system, we can maximise the amount of cargo carried in relation to deadweight tonnage. The onboard distribution of heavy and light containers, and subsequently total cargo weight, should...

Open the catalog to page 10

Critical components of the container stowage solution With regard to deck systems, the different components of the container stowage solution have individual design features for different container loading scenarios, which depend on the cargo profile, the number of Lashing system Cargo system index value of 40’ containers When determining the container stowage system, it is important to consider the effect of different loading requirements that have an impact on individual components. From the 40’ container loading example, it can be seen that major effects come from the container lashing...

Open the catalog to page 11

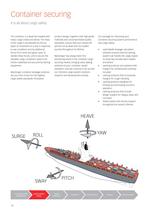

Container securing It is all about cargo safety. The container is a weak box loaded with heavy cargo inside and above. The mass of the cargo is accelerated by the six types of movement of a ship in response to sea conditions and by additional forces from wind and green seas. To handle these forces, and to secure the valuable cargo, containers need to be further stabilised and secured by lashing equipment. MacGregor container stowage solutions are your first choice for the highest cargo safety standards. Innovative product design, together with high grade materials and uncompromised quality...

Open the catalog to page 12

Static and dynamic components The forces acting on the container in both longitudinal and transversal sliding depend on the static and dynamic forces. The static force is gravity and the dynamic forces are those caused by the ship’s motion (roll, pitch, heave, yaw, surge and sway), windage and heavy seas. Your cargo profile requirements Lashing system design System verification Lifetime support

Open the catalog to page 13

Code of container position Definition Position of a stack Example of a 20’ stack → 03 - 06 Position of a container → Bay no. Your cargo profile requirements Lashing system design System verification Lifetime support

Open the catalog to page 14

Container dimensions (*) The tolerances to be applied for S and P governed by the tolerances shown for the overall length and width in the ISO 668 and ISO 1161. Your cargo profile requirements Lashing system design System verification Lifetime support

Open the catalog to page 15

Comparison of container sizes ISO Side view (*) Containers are not standardised by ISO. Given dimensions may differ from container variants. (1) Weights are maximum gross weights and may differ from container variants. Tolerances: Width: +0 - 5 mm for all containers Height: +0 - 5 mm for all containers Length: +0 - 10 mm for 53’ - 30’ containers Common for all containers is the transverse measure from centre to centre point of the holes of corner fittings, approx. 2259 mm. Your cargo profile requirements Lashing system design System verification Lifetime support

Open the catalog to page 16

Common container spaces* *also other spaces/distances possible Container centre distances Y [mm] 203 Transversal distances of wide-body containers Container width [mm] Min. container centre distances Y [mm] Special attention must be given when wide body containers are stowed in cellguides. Your cargo profile requirements Lashing system design System verification Lifetime support

Open the catalog to page 17

Container securing system design What do we need to know about your new ship project? Our container securing system design process starts in close cooperation with our customers by creating a full picture of the ship’s cargo profile and defining effective lashing patterns. Crucial information like weight distribution calculations and the comparison of total costs for different container securing systems help our customers to decide the best fit for their ships. A container stowage plan can also be designed as part of a complete container securing system. We begin by defining the lashing...

Open the catalog to page 18All Cargotec catalogs and technical brochures

-

DCT80-90

5 Pages

-

ECG50-90

7 Pages

-

ECF50-90

7 Pages

-

ECH_DCF70-100

12 Pages

-

The Ego Cabin

16 Pages

-

DRT450

5 Pages

-

Kalmar_DRT

5 Pages

-

DRF400-450

20 Pages

-

Gloria

9 Pages

-

Kalmar RTG smartpower

12 Pages

-

Kalmar shuttle carriers

7 Pages

-

618i series

8 Pages

-

T2

5 Pages

-

SB-ELT9

7 Pages

-

SB-ELT9G

7 Pages

-

DCF50-90

7 Pages

-

DCG90-180

9 Pages

-

DCF180-520

9 Pages

-

CLF Cablelifts

2 Pages

-

XR Low-built range hooklifts

8 Pages

-

XR10S

2 Pages

-

XR8S

2 Pages

-

XR 7S

2 Pages

-

XR 5S

2 Pages

-

XR 3S

2 Pages

-

XR 2S

2 Pages

-

TT618i

8 Pages

-

TT616i

12 Pages

-

Kalmar TR626i-TR632i

8 Pages

-

Shuttle Carrier

20 Pages

-

Kalmar RTG

12 Pages

-

Quay Cranes

16 Pages

-

Logstackers

6 Pages

-

Fork lift trucks 18-52 tonnes

16 Pages

-

Fork lift trucks 9-18 tonnes

16 Pages

-

Kalmar Automatic stacking crane

12 Pages

-

Reachstackers 40-45 tonnes

20 Pages

-

Kalmar Straddle carriers

12 Pages

-

Kalmar Loaded container handler

12 Pages

-

Kalmar TT612d

4 Pages

Archived catalogs

-

Hiab Moffett Concept

16 Pages

-

Hiab SL Skiploader Range

8 Pages

-

Hiab The XS concept

48 Pages

-

HIAB T-Cranes Range

12 Pages