Website:

Carbolite Gero

Website:

Carbolite Gero

Group: VERDER Scientific

Catalog excerpts

TEMPERATURE TECHNOLOGY coal, coke & testing furnaces

Open the catalog to page 1

Established in 1938, Carbolite has become a leading international manufacturer of quality thermal quality control, research, pilot Discharge of coke from a variable width moving wall coking oven. iron ore evaluation, have become established as the standard equipment used in coal laboratories, power plants and steelworks throughout the world. The range includes bench top laboratory models for routine testing and large pilot plant scale products, some of which are unique to Carbolite, such as the variable width hearth moving wall coking oven which can be found in coal research facilities as...

Open the catalog to page 2

facilities nan he incorporated as an option. Both furnaces comply with the following industry standards: BS 1016, Part 4, ISO 344 & 1171, ASTM VOLATILE MATTER FURNACES Two models are available to meet the different test methods of The model VMF 10/6 meets the requirements of ISO 562 and is a chamber furnace with a maximum temperature of 1000°C. Chamber size is of 655 x 435 x 610 mm (HWD). Powerful open spiral heating elements, supported in lightweight ceramic fibre insulation give fast heating. A sophisticated algorithm in the digital temperature controller ensures fast recovery of...

Open the catalog to page 3

pilot plant equipment The following products comprise the range of larger units and are separately detailed on individual specification data sheets. MOVING WALL COKING TEST OVEN The oven rated at 1250°C is designed for testing suitably granulated and graded coals for coking under accurately controlled conditions. The oven is designed to allow pressure generated during the coking to be exerted against a fixed wall on one side Moving wall test oven. of the chamber and a moving wall on the other. This pressure is measured by a load transducer actuated by the moving wall. The recommended width...

Open the catalog to page 4

measure wall pressure during Vertically split coking oven. at {he centre of the charge and variation in charge height during coking. The results obtained will be an approximate average of the larger scale moving wall coking oven Various test furnace test rigs Iron ore reducibilty test rig. specification data sheets. Please request further information. They include: determination of reducibility of iron ores • Low temperature disintegration test - method using cold tumbling after static reduction Aston Lane, Hope, Hope Valley S33 6RE, England Determination of relative free swelling index...

Open the catalog to page 5

Established in 1938, Carbolite has become a leading international manufacturer of quality thermal quality control, research, pilot Discharge of coke from a variable width moving wall coking oven. iron ore evaluation, have become established as the standard equipment used in coal laboratories, power plants and steelworks throughout the world. The range includes bench top laboratory models for routine testing and large pilot plant scale products, some of which are unique to Carbolite, such as the variable width hearth moving wall coking oven which can be found in coal research facilities as...

Open the catalog to page 6

facilities can be incorporated as an option. Both furnaces comply with the following industry standards: BS 1016, Part 4, ISO 344 & 1171, ASTM VOLATILE MATTER FURNACES Two models are available to meet the different test methods of The model VMF 10/6 meets the requirements of ISO 562 and is a chamber furnace with a maximum temperature of 1000°C. Chamber size is of 655 x 435 x 610 mm (HWD). Powerful open spiral heating elements, supported in lightweight ceramic fibre insulation give fast heating. A sophisticated algorithm in the digital temperature controller ensures fast recovery of...

Open the catalog to page 7

can be pre-set, including automatic gas switching which minimises operator supervision. A new digital imaging version is also available allowing digital pictures to be viewed more quickly and monitoring can be performed remotely via a PC. For laboratories where a small number of samples are processed a manual version is available which requires visual observation of the sample via a telescope. Model type CAF 16/38 has a maximum Detailed specifications are available and special SULPHUR & CHLORINE CONTENT Combustion tube furnaces with a maximum operating temperature of 1400°C are designed for...

Open the catalog to page 8

pilot plant equipment The following products comprise the range of larger units and are separately detailed on individual specification data sheets. MOVING WALL COKING TEST OVEN The oven rated at 1250°C is designed for testing suitably granulated and graded coals for coking under accurately controlled conditions. The oven is designed to allow pressure generated during the coking to be exerted against a fixed wall on one side Moving wall test oven. of the chamber and a moving wall on the other. This pressure is measured by a load transducer actuated by the moving wall. The recommended width...

Open the catalog to page 9

measure wall pressure during Vertically split coking oven. at lhe cen{re Qf the charge and variation in charge height during coking. The results obtained will be an approximate average of the larger scale moving wall coking oven Various test furnace test rigs Iron ore reducibilty test rig. specification data sheets. Please request further information. They include: determination of reducibility of iron ores • Low temperature disintegration test - method using cold tumbling after static reduction Aston Lane, Hope, Hope Valley S33 6RE, England Determination of relative free swelling index...

Open the catalog to page 10All Carbolite Gero catalogs and technical brochures

-

CAF G5

2 Pages

-

Overview - Ovens & Furnaaces

16 Pages

-

Materialography

20 Pages

-

PF

5 Pages

-

PN

4 Pages

-

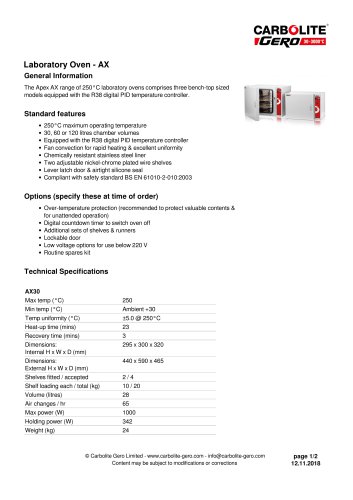

AX

2 Pages

-

Furnaces for Precious Metals

4 Pages

-

Furnaces for Precious Metals

4 Pages

Archived catalogs

-

Verder Scientific Product News

16 Pages

-

LHT

6 Pages

-

RHZS - Rotating Tube Furnace

2 Pages

-

Verder Scientific

20 Pages

-

Furnaces & Ovens for Aerospace

12 Pages

-

Batch Heat Treatment Furnaces

8 Pages