Website:

CAPACITEC

Website:

CAPACITEC

Group: Capacitec Us

Catalog excerpts

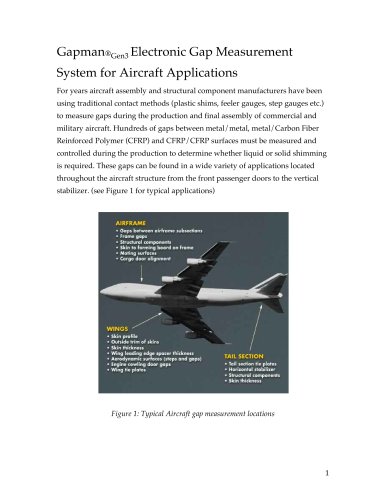

sales@Capacitec.com 87 Fitchburg Rd. Ayer, MA 01432 www.Capacitec.com A High Precision Noncontact Electronic Hole Measurement Gauge for Aerospace Structures Commercial and Military Aircraft, Launch Vehicles and Satellites have a significant number of fastener holes in their structures. In large aircraft such as the Boeing 747, The C-17 Military Transport or the new Airbus A380 it is estimated that the number of holes is well over one million. Some of these fastener holes are more critical than others. In aircraft, holes that get a high level of attention from QC engineers are those that interface the connection of the wings of the fuselage (front and back), the vertical stabilizer as well as fasteners in the engine mounts that keep the engines attached to the wings. In launch vehicles examples of critical fasteners holes are the ones located where the outside surface of the launcher is attached to the main structure. As the pressure increases on aerospace structure manufacturers to develop faster, more efficient and higher quality methods of assembly they are looking for more modern ways to measure holes. Traditional hole measurement methods Today many critical fastener holes are being measured using traditional contact methods of hole measurement such mechanical bore gauges and go/no go mechanical gauges. Mechanical bore gauges are made up of a mechanical measurement interface (such as split ball), which is attached to a standard dimensional measurement instrument such as a dial indicator. In the case of a split ball device the diameter size changes in relation to the spreading of the balls. In order to calculate the average diameter of a hole the operator must make measurements at 0° and 180 degrees at in top middle and bottom of each hole. This method is typically used where high precision important and the number of holes to be measured is limit. This method has advantages if the number of holes is limited and the accuracy level required is low but has distinct disadvantages when companies are looking to measure a high volume of holes in an accurate and automated method. In the assembly of aircraft, some fastening applications are more critical than others. In the most critical applications aircraft manufacturers often use tapered bolts. A good example of one of the most critical fastener applications where tapered bolts are used is when aircraft assemblers attach the front and rear wings to the fuselage of the plane. Accurately measuring the full-length diameter of the boreholes drilled for these bolts presents a particularly difficult measurement challenge. The traditional method to measure the fit between the tapered bolt and hole is referred to as the “blue ink” method. This dated procedure gets it’s name from the way it works. In this case operators start with a mechanical pin that is the same size as the specified tapered bolt for that hole. The pin is then painted with blue ink and hammered into the hole. Once removed, the operator visually inspects how much blue ink remains on the bolt. The less ink remaining, the 1

Open the catalog to page 1

sales@Capacitec.com 87 Fitchburg Rd. Ayer, MA 01432 www.Capacitec.com better the fit. The advantage of this method is low cost. The disadvantages are the difficulty of the procedure, poor measurement repeatability and subjectivity from operator to operator. An additional disadvantage of this method is cost of a bad measurement. If the operator selects the wrong sized bolt (e.g. the bolt will be oversized) and the tapered bolt is forced into the tapered hole during assembly, it is very difficult, time consuming and costly to remove the oversized bolt from the hole. One thing in common with...

Open the catalog to page 2All CAPACITEC catalogs and technical brochures

-

508-SW SWITCHING AMPLIFIER

2 Pages

-

520 AMPLIFIER

4 Pages

-

HPC-500

5 Pages

-

HPC-375

5 Pages

-

HPC-150

5 Pages

-

HPC-75

5 Pages

-

HPT-40

3 Pages

-

HPB-500

7 Pages

-

HPB-150

7 Pages

-

HPB-75

7 Pages

-

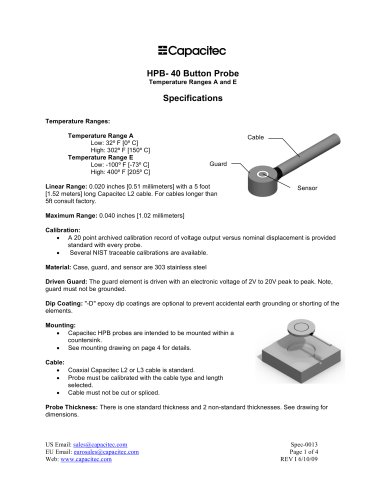

HPB-40

4 Pages

-

HPC-500

4 Pages

-

HPC-375

4 Pages

-

HPC-150

4 Pages

-

HPC-75

4 Pages

-

HPC-40

3 Pages

-

GapmanGen3 Brochure

4 Pages

-

Coater Bargrafx Software

5 Pages

-

GAPMANGEN3

4 Pages

-

Aerospace

8 Pages

-

Capteura® 200 Series System

4 Pages

-

Slot Die Coater Brochure

4 Pages

Archived catalogs

-

Disc Brake

4 Pages

-

Standard products

12 Pages