Website:

CAPACITEC

Website:

CAPACITEC

Group: Capacitec Us

Catalog excerpts

Noncontact Displacement Sensors in Automotive Manufacture Over the past decade, breakthroughs in sensor technology have improved the automobile both inside and out. Most consumers are aware of the benefits that sensors have contributed to automotive subsystems such as air bags, automatic braking systems, and load leveling systems. Less obvious is the increasing role of sensors in R&D, QC, and manufacturing methods that are being driven by automakers’ outsourcing certain subassemblies to Tier 1 suppliers such as Robert Bosch, Delphi, Visteon, and Continental Teves. These companies now supply complete suspensions, wheels, brakes, transmissions, and other components to Toyota, DaimlerChrysler, GM, Ford, and Volkswagen, among other global manufacturers. The automakers’ role has also changed over the years from vertically integrated manufacturer to major assembly houses. Tier 1 suppliers are therefore subject to very stringent quality system requirements such as Q1 and QA9000, which place emphasis on building high-quality parts the first time, every time. As new QC practices such as in-process and 100% parts inspection become more commonplace, capacitive noncontact displacement and thin gap sensors are being used in an increasing number of locations throughout the automotive manufacturing process (see Figure 1). As component and subassembly dimensions shrink, the sensors used to measure them must also undergo miniaturization. Displacement sensors, for example, often must fit into locations with diameters <1 mm, where they measure gaps as small as 0.009 in. (0.23 mm). Other requirements include: • Operating temperatures to 1832°F (1000°C) • Overall diameter reduced to 0.004 in. (100 microns) • Accuracy to 8 ìin. (0.2 microns) • Immunity to magnetic fields • Response up to 200 kHz • On-vehicle DC modular electronics Braking Systems (Disc and Drum) The rugged modular electronics in Capacitec’s new line of disc brake wear analysis sensors (see Figure 2) are capable of taking high-temperature (932°F, 500°C) Advances in noncontact displacement sensors are bringing new levels of quality and efficiency to the research labs and assembly lines of automakers worldwide. Bryan Manning and Robert Foster, Capacitec, Inc. TRANSPORTATION Figure 1. From engine piston and valve design, to braking and suspension system testing, noncontact displacement and gap measurement systems help engineers design better cars and trucks. SUNROOF GAP CONTROL AXLE RUNOUT WINDSHIELD FABRICATION DISC AND DRUM BRAKE WEAR ANALYSIS • TURBOCHARGER • PISTON • GEARBOX • AUTOMATIC TRANSMISSION

Open the catalog to page 1

TRANSPORTATION dynamic brake system measurements both in laboratory dynamometers and on the vehicles at test track facilities. By measuring displacement variables on a brake rotor in motion, data can be collected and analyzed to show several characteristics, such as: • Rotor runout (TIR) • Rotor thickness variation • Rotor coning • Thermal expansion • Plate-to-plate orientation (V-ing, barreling) • Wobble • Ovality The high-temperature and high-pressure conditions brought on by emergency braking or prolonged downhill deceleration can deform the brake drums used on heavy trucks. Brake...

Open the catalog to page 2

vant to an understanding of piston assembly complex dynamics. Vehicle Assembly Consistent and precise measurement of the various gaps around a vehicle’s exterior surface is a difficult problem because of the wide variety of gap locations, each with its own requirements. The variables include: • Different materials to be measured (e.g., metal, rubber, composites) • Various contact/noncontact requirements (prevention of scratches) • Wide range of gap sizes (0.23–10 mm) • Wide range of target geometry (e.g., flat to radius, radius to sharp edge) • Signal processing differences • Instrument...

Open the catalog to page 3All CAPACITEC catalogs and technical brochures

-

508-SW SWITCHING AMPLIFIER

2 Pages

-

520 AMPLIFIER

4 Pages

-

HPC-500

5 Pages

-

HPC-375

5 Pages

-

HPC-150

5 Pages

-

HPC-75

5 Pages

-

HPT-40

3 Pages

-

HPB-500

7 Pages

-

HPB-150

7 Pages

-

HPB-75

7 Pages

-

HPB-40

4 Pages

-

HPC-500

4 Pages

-

HPC-375

4 Pages

-

HPC-150

4 Pages

-

HPC-75

4 Pages

-

HPC-40

3 Pages

-

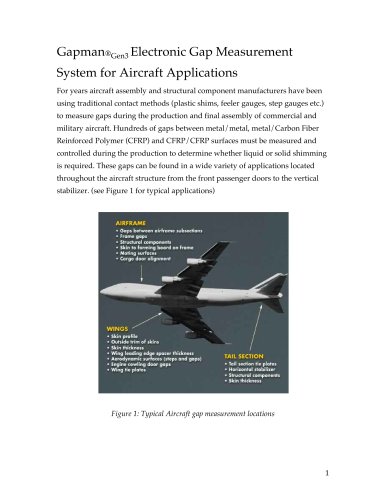

GapmanGen3 Brochure

4 Pages

-

Coater Bargrafx Software

5 Pages

-

GAPMANGEN3

4 Pages

-

Aerospace

8 Pages

-

Capteura® 200 Series System

4 Pages

-

Slot Die Coater Brochure

4 Pages

Archived catalogs

-

Disc Brake

4 Pages

-

Standard products

12 Pages