Website:

CAPACITEC

Website:

CAPACITEC

Group: Capacitec Us

Catalog excerpts

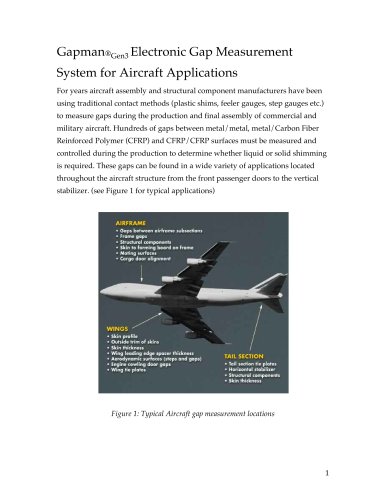

A High-Precision Noncontact Electronic Gap Measurement Gauge The first portable capacitive gap measurement tool, originally developed for aircraft manufacturing, now has a digital output that expands its range of applications. Bryan Manning and Robert L. Foster, Capacitec S hims and fcclcr gauges, the tools tradi-tionally used in gap measurement, exliibit onlv marginal acenracv when the tolrance must be better than 0.001 in. (0.025 mm). Plastic shims can \'arv in thick-ness bv 0.0003 in. (0.0076 mm), and feelcr gauge data tend to be subjective the "feel" will varv froni one user to the next. A second problem with contact measure闭ment methods is that their accuracv is redueed over time. The constant rubbing against hard surfaces during the measurement process causes wear on the shims and feeler gauges, and can also damage the highlv polished surfaces found in some apͭplications. Third, shims are often removed after setup and there is no wav to be sure that the gap is still uithin spee. A major U.S. diesel engine manufacturer undertook a study of thse problems be-cau.se fuel economy, guaranteed under service warranty, varied widelv with the final adjustments made to fixed gaps on the spring-load-adjusted intake and exhaust valves. M譩tal shims were used to make thse tweaks. The desired gap sizes were -0.015 in. (0,38 mm) for the intake and -0.030 in. (0.76 mm) for the exhaust valves. The results of the studv indicated that there was a si/.able discrepancy in the measurement results among six tecfmicians, ail of whom were using the sanic tools and trving to set the saine gaps. The gap sizes varied from one another l)v amounts ranging from 0.001 m. (0.025 mm) to 0.006 in. (0.015 mm), with an average variation of 0.003 in. (0.076 mm) or 10% of reading for the Several trends in quality and process control are pushing QC personnel toward increased docu譭mentation and recording of the mcasurements tlicv per-form. QC schemes such as SPC and TQM have be-come more rigorous. ISO 9000 represents a eral aeceptance even though interest in it re-mained alive in the aerospaee, semiconduc-tor, automotive, and in-dustrial arenas. In the late 1980s, Capacitec and Boeing Airͭcraft began a cooprative development pro魭 new set of manufacturing standards. Once mea-surements are obtained, gram that resulted in the design of the world's first portable tlicv must be transferred into the local qualitv Sysͭtem. Manuallv writing down the information on X/R charts, for example, and then inputting it to an Photo 1. lich Capman kit is slnpped in a wah'rprimf industrial case that also con-tains standard components such as a hat-tery charger, RS'-2i2 and ground cables, and a 1-puint gap calibration block. Additional optional components arc avail-ahlc fur spcial applications. th.in gap measurement instrument, the analog Capman. Introdueed in 1993, and sold for a number of applications, this device satisfied SPC data program on a PC offers yet another opportunitv for error. Automaticallv gathering and transferring th驨se data electronieallv to the appropriate quality program would save time and monev and improve the qualitv of the recorded data. Advancing the Technology Noncontact capacitive sensors and sensor Systems have been used bv industrv to meas-ure gaps sinee the 1960s, and bv the nuelear fuel industry sinee 1978 to measure gaps be-tween fuel rods. Even though the sensors of that time could be as thiu as 0.020 in. (0.50 mm), thev ran into trouble trving to measure gap sizes <0.040 in. (1.0 mm). This limitation, and the laek of svstcm main' of the eustomers' requirements, including portabilitv, im-proved repeatabilitv, and interface to SPC' data loggers. Customer-Driven Product Development The analog Capman was a major step toward portable gap measurement, but needed further development to expand its range of applications. Capacitec therefore invested in an extensive customer-driven product development program. Before anv product designs were drawn up, a l()-page survey was sent to and eompleted b\' more tlian 50 potential users. In addition, dozens of eustomers were interviewed at trade shows and beta site meetings. The result was a prioritized list of kev requirements for

Open the catalog to page 1

hekl gap nieasurement instrument: Easy to Use Simple to operate even for new or unskilled employes Preset to tlie spcifie application Ktfortless interface with quality control svstems Flexible One instrument for multiple nieasurement locations Reaelies gaps very difficult to access Pr驩cise on ail conductiye surfaces Rcduces Gost Low eost per nieasurement Longer ])roeess/equipment uptinic Elimintes startup serap Elimintes scratches on product With this input, Gapacitec finalized tlie product design to inelude the followmg ke\' features: ⢕ Factorv preset to eustomer spec. Digital output...

Open the catalog to page 2All CAPACITEC catalogs and technical brochures

-

508-SW SWITCHING AMPLIFIER

2 Pages

-

520 AMPLIFIER

4 Pages

-

HPC-500

5 Pages

-

HPC-375

5 Pages

-

HPC-150

5 Pages

-

HPC-75

5 Pages

-

HPT-40

3 Pages

-

HPB-500

7 Pages

-

HPB-150

7 Pages

-

HPB-75

7 Pages

-

HPB-40

4 Pages

-

HPC-500

4 Pages

-

HPC-375

4 Pages

-

HPC-150

4 Pages

-

HPC-75

4 Pages

-

HPC-40

3 Pages

-

GapmanGen3 Brochure

4 Pages

-

Coater Bargrafx Software

5 Pages

-

GAPMANGEN3

4 Pages

-

Aerospace

8 Pages

-

Capteura® 200 Series System

4 Pages

-

Slot Die Coater Brochure

4 Pages

Archived catalogs

-

Disc Brake

4 Pages

-

Standard products

12 Pages