Website:

CANTEK Cold Storage - Meat Processing

Website:

CANTEK Cold Storage - Meat Processing

Group: CANTEK GROUP

Catalog excerpts

Meat Technologies The art of meat technologies

Open the catalog to page 1

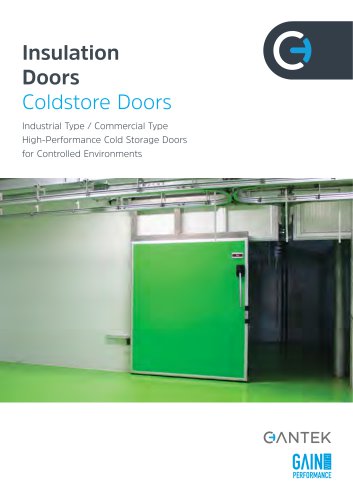

About Cantek Group Cantek is a food storage and processing expert. For over 30 years, Cantek has successfully completed more than 15.000 projects in 65+ countries. Cantek produces high technology equipment and realizes turnkey cold storage, slaughterhouse / meat processing and plant factory projects worldwide. With a closed production area of 40.000 m2, Cantek offers complete solutions from one hand including project development, production of all equipment, facility installation, service, warranty, remote controlling and managing systems. In addition, Cantek provides savings in energy...

Open the catalog to page 2

PROCESSING TECHNOLOGIES Meat I Poultry I Fish Meat Slaughterhouse & Processing Poultry Slaughterhouse & Processing Fish Processing Mobile Solutions Meat & Poultry Farming & Quarantine Project Consultancy Turnkey Solutions

Open the catalog to page 3

Processing Technologies Project Study Approaches Cantek offers their customers different project opportunities: Basic Process Project Solutions From concept to delivery. Complete Project Solutions From concept to handover with a turnkey or specific scope project. Consultancy Services Preliminary detail engineering with a turnkey or specific scope project. Basic Process Project Solutions Planning, manufacturing and installing machines at specific steps of each project. Slaughtering and further processing. Cooling technologies, cold room panels and doors. Complete Project Solutions (Turnkey...

Open the catalog to page 5

Processing Technologies Consultancy Services (Turnkey or Specific Scope Project) Cantek provides consultancy services for preliminary designs of turnkey and tailor-made projects. The consultancy services include (but are not limited to) the slaughtering process; cooling; insulation panels & doors; architectural project’s structural, civil, electrical, and mechanical works. The scope of each project is determined in cooperation with our customers. Cantek collects all the data and evaluate it in line with the experience and with the purpose to create sustainable and suitable projects for...

Open the catalog to page 6

Processing Technologies Project Study Approaches Basic Process Project Complete Project (as a turnkey or tailor-made project) Conceptual Studies No detailed engineering, 2D sample layout, budgeting cost Consultancy Services Agreement for preliminary design studies Detailed project engineering services for turnkey and tailor-made projects Commercial Contract Product supply agreement 2D layouts & quotation according to the clients request Technical data sheets Limit of supply & responsibilities Terms of delivery & payment Project work schdule & planning Consultancy Services Preliminary Design...

Open the catalog to page 8

Processing Technologies Order Confirmation Client signs order confirmation Initial down payment by client Confirmation of production according to contract terms Detailed Engineering, Supplying & Production Project drawings (plans & sections) related to agreed and confirmed details Machines & equipment production & supply Detailed Engineering, Supplying & Production Order Confirmation 06 Installation According to the scoop of the contract, supervisor or full installation team

Open the catalog to page 9

Meat Processing Facilities

Open the catalog to page 10

Today, there are around 1.3 billion cattle, 1.2 billion sheeps and 1 billion goats around the world. Although the global demand for meat is varying on different rates in different regions, there is a steady increase. Thus the most important parts of the meat industry are slaughterhouses and meat processing plants. Cantek, having established major R&D activities and educational publications in the meat industry, offers services on all the stages of meat production from paddock to reaching consumers. Cantek produces slaughterhouse equipment and advanced meat processing systems, along with...

Open the catalog to page 11

Meat Processing Technologies Live Animal Live Animal Slaughtering Process Steps of Meat Processing Edible Offal Carcass Cold Rooms Carcass Dispatch Meat Deboning Further Meat Processing Product Dispatch Meat Dispatch

Open the catalog to page 13

Meat Processing Technologies Bleeding Live animals are kept in paddocks before slaughtering. All necessary conditions are fulfilled in accordance with the principles of animal welfare. Animals are kept under control in the slaughtering box and their movement is prevented. Their stress levels are controlled for their own welfare and also to obtain high-quality meat. Different types of slaughtering boxes can be used to comply with the animal welfare and Halal standards. Conveyors help controlling the animal and speeding up the slaughtering process. After slaughtering, the animals are hung on...

Open the catalog to page 14

Meat Processing Technologies The hind legs are cut while the cattle are transferred from the bleeding line to the processing line. Then, the skin is removed from the animal. Following the dehiding process, white and red offal are removed. Afterwards, the carcass is split and forwarded to the veterinary control point. After weighing and washing, the carcass is transferred to the cooling area.

Open the catalog to page 15

Meat Processing Technologies Carcass Coldrooms Offal Processing Optimum storage environment for short and long term storage and minimum weight loss is ensured during the cooling process. Energy-efficient and environmentally-friendly cooling system design. Equipped with high-quality sandwich panels and suitable lighting condition. Offal contributes to the profitability of the meat processing industry. Cantek uses the newest technology for offal cleaning which increases the value of the edible byproducts. Suitable storage options are available to meet customer demands.

Open the catalog to page 16

Meat Processing Technologies Meat Deboning & Packaging Further Processing Following the cooling process, carcasses are transferred to the deboning area to be cut into small pieces. Butchers perform the deboning according to the customer’s demands. Primal cuts will be classified and transferred to the packaging area. High-technology packaging methods are provided to lengthen the shelf life of the meat. Further processing lines are designed to produce different end products (meatballs, salami, sausages, ham etc.) They are equipped with special processing machines and conditioning rooms...

Open the catalog to page 17All CANTEK Cold Storage - Meat Processing catalogs and technical brochures

-

MOBILE SLAUGHTERHOUSE

28 Pages

-

snowworld

6 Pages

-

REFERENCES

62 Pages

-

MOBILE SOLUTIONS

14 Pages

-

Octoled

8 Pages