Catalog excerpts

P4| SCROLL SHEAR MACHINES FOR STRIP CUTTING AND STAMPING FOR STRIP FEED ENDMAKING LINES Technology that keeps you ahead SOUDRONIC GROUP

Open the catalog to page 1

STRIP CUTTiNG AND STAMPiNG SYSTEMSP4 STRIP STAMPING PRESS Strip feed press with single and double tooling for stamping and deep drawing of caps. • Strip feed press for round, non-round ends and shells • Strip feed press for cap shells • operated with single or double die tooling • Mechanical strip feed system for automatic feeding with single-scrolled, double-scrolled or straight-sided strips P4 Strip Stamping Press P4 STRIP FEED PRESS SiNGLE oR DouBLE-DiE STAMPiNG PRESS ACCESSoiRES Max. press force 320 kN lubricating system Cutting diameter max. 125 mm (double tool) 250 mm...

Open the catalog to page 2

75 MM STROKE END DiAMETER MM INCH Single or double curler with conveying equipment from the press and to the double head liner for round ends and shells. SCROLL SHEAR This machine is capable of producing scrolled strips for end production. Unlike the slitter system with rotary cutters, the CUT-o-MAT scroll shear is a stamping shear, processing straight trimmed or primary scrolled sheets. • Highly versatile: Can be used to process bright, lacquered and printed sheets made of tinplate, TFS, aluminium • Flexible modular design • optimum handling • Minimal changeover times • Modular systems...

Open the catalog to page 3

SCROLL STRIP MAGAZINE Magazine for fully automatic collection of scroll strips on pallets SCROLL SHEAR SCROLL SHEAR (FOR PRiMARY SCROLL SHEETS) OPTiONS Sheet length 500-1150 mm Bending facility Sheet width 650-1040 mm Column-guided tooling Possible sheet gauge 0,14-0,40 mm Carbide cutters Min. strip width 100 mm Vacuum generator Max. strip width 294 mm Blow air Number of strokes 60-130/min Spreader suction cups SCROLL SHEAR WITH TRIMMING DEVICE COMBiNED SCROLL SHEAR AND SiNGLE GANG SLiTTER OPTiONS Sheet length 700-1150 mm Bending facility...

Open the catalog to page 4All Cantec catalogs and technical brochures

-

Capmaking systems CAP-O-MAT

8 Pages

-

Multi-die systems END-O-MAT

8 Pages

-

UNIPRESS

2 Pages

-

Soudronic Company

32 Pages

-

Testing systems

2 Pages

-

ECONOMIC CURING SYSTEMS

6 Pages

-

Seam protection systems

8 Pages

-

SQUAREPACK ® line to produce

2 Pages

-

BODYSHAPER

2 Pages

-

INLINE TACTILE MARKING UNIT

2 Pages

-

Sheet Feeder

6 Pages

-

END-O-MAT

3 Pages

-

END-O-MAT press

2 Pages

-

liner

1 Pages

-

Cap making systems

8 Pages

-

CAN-O-MAT Aerosol

2 Pages

-

Powder Monitor SPM-2

2 Pages

-

Belt Conveyor Transfer TX2

1 Pages

-

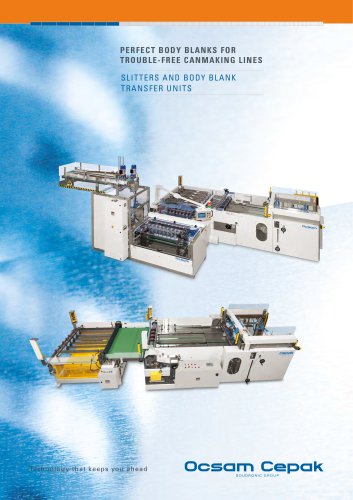

Cepak Slitter Equipment

4 Pages

-

Cepak Slitters

6 Pages

-

HEAt SEALING SYSTEM

2 Pages

-

Cepak Hybrid Slitters

2 Pages

-

Automatic canbody welders

6 Pages

-

BODYPACK

2 Pages

-

END-O-MAT Multi-die systems

8 Pages