Catalog excerpts

SQUAREPACK® line to produce pyramidal cans suitable for UN-approval THIS LINE IS DESIGNED TO PRODUCE PYRAMID-SHAPED CANS WHICH CAN THEREFORE BE STACKED DURING PALLETISATION. EXPANSION IN TWO OPERATIONS: 1° conical expansion 2° pyramid-shape expansion. With one set of tooling, up to 60 cpm With two sets of tooling, up to 100 cpm Conical expansion Pyramidal expansion ADVANTAGES: The edge panel deection is reduced by 50%. This is a key parameter to get a constant seam overlap for UN approval. Standard technology Technology for UN-approved cans Cylindrical body Direct pyramidal expansion Cylindrical body 1st step: conical expansion 2nd step: pyramidal expansion

Open the catalog to page 1

SEAMING PROCESS WITH 2 STATIONS: Additional curling operation 1st seaming operation. 2nd station: 2nd seaming operation with 2 sets of 2 rollers. ADVANTAGES: Two-side curled ends can be processed End hook and overlap can be easily mastered The exibility of our process allows to seam different kinds of bottoms. Technical specications of the Squarepack 5 Volumetric capacity Min/Max length Min/Max width Min/Max height Maximum cycle/minute Design Axess - © SABATIER SAS - 02/2009

Open the catalog to page 2All Cantec catalogs and technical brochures

-

Capmaking systems CAP-O-MAT

8 Pages

-

Multi-die systems END-O-MAT

8 Pages

-

UNIPRESS

2 Pages

-

Soudronic Company

32 Pages

-

Testing systems

2 Pages

-

ECONOMIC CURING SYSTEMS

6 Pages

-

Seam protection systems

8 Pages

-

BODYSHAPER

2 Pages

-

INLINE TACTILE MARKING UNIT

2 Pages

-

Sheet Feeder

6 Pages

-

END-O-MAT

3 Pages

-

END-O-MAT press

2 Pages

-

liner

1 Pages

-

Cap making systems

8 Pages

-

CAN-O-MAT Aerosol

2 Pages

-

Powder Monitor SPM-2

2 Pages

-

Belt Conveyor Transfer TX2

1 Pages

-

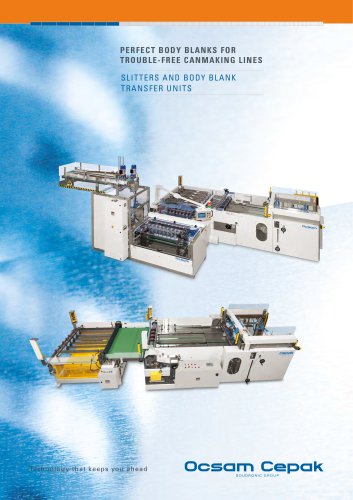

Cepak Slitter Equipment

4 Pages

-

Cepak Slitters

6 Pages

-

HEAt SEALING SYSTEM

2 Pages

-

Cepak Hybrid Slitters

2 Pages

-

Automatic canbody welders

6 Pages

-

BODYPACK

2 Pages

-

END-O-MAT Multi-die systems

8 Pages