Catalog excerpts

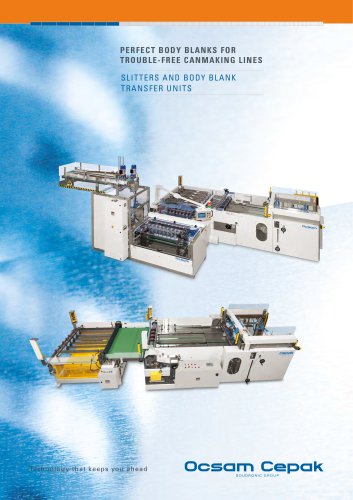

perfect body bl anks for troubl e-free canm aking lines slitters and body blank transfer units Technology that keeps you ahead

Open the catalog to page 1

b o d y bl a n k t r a n s f e r u n i t s TPM-S l The fastest, most advanced and flexible transfer unit l Custom executions to match any line layout l Also able to feed simultaneously two welders running the same blank size (see picture) TPM The upgraded body blank transfer unit featuring: l Blank stack over-turning or non-overturning options built-in l Pivoting transfer arm l Rotating pincer to match any line layouts l Touch-screen panel on a pivoting arm TP1001 (GP) l The basic body blank transfer unit l Inexpensive and effective l Blank stack over-turning or non-overturning options...

Open the catalog to page 2

Sl i t t e r s Single-dog transport belts with independent «servo drive» motor. Extra sturdy symmetric cast iron frames. Double bearing housings on both cutters shaft ends to guarantee a bow-free cut. Squareness and trim adjustments on first table.

Open the catalog to page 3

TSN211 The ideal duplex slitter for any canmaking line, a «must» for high-speed lines. l State-of-the-art technology l Highest speed l Precision accuracy l Outstanding efficiency l Perfect handling of thinnest plate

Open the catalog to page 4

SGS The «Ocsamazing» slitter for any aerosols and general line can producers. A canmaker’s dream comes true!! l Completely automatic and instantaneous body blank height changeover l Body blank length changeover in just a few minutes l Possibility to store and recall hundreds of different sheet cutting layouts l State-of-the-art technology such as «ironless » linear motors, servo motors, highspeed hydraulics, touch-screen panel and a revolutionary wear and maintenance- free guillotine ram guide system (patent pending)

Open the catalog to page 5

Two pincers driven by independent linear motors to guarantee a perfect dimensional accuracy and consistency of the body blank height (BBH), from the first strip to the last. High-speed hydraulic guillotine. Perfect handling of any strip sizes down to 45 mm width (BBH). Back squaring system by means of two independent linear motors. Traditional rotary cutters and guide rollers on a 110 mm diameter shaft for bow-free body blank length (BBL) cuts. Extra large and user-friendly interface (touchscreen panel). Integrated Digital Measuring Device (DMD-S) for fast and accurate setting of the rotary...

Open the catalog to page 6

a c c e s s o r i e s s ta c k e r s RE N/RE N-S Blank stackers RA F/RAS /RAS V/RAS -1/RAS -2 Sheet/strip/blank stackers CR Lacquer margin control device. DMD/DMD-S Digital measuring instrument for a quick and precise positioning of the cutters. RT Precision cutter grinder. GRTS60 - GRTS60/1 Pair of carbide cutters with OCSA M mechanical hubs and drive rings. ERN (FOR TS N 211) Magnetic belt to remove trims (scrap) simultaneously from first and second table. ERN-S (FOR SGS) Magnetic belt to remove trims before and after the guillotine.

Open the catalog to page 7

Subject to modification 2000 E 07.07, printed in Switzerland © Copyright by Ocsam Impianti s.r.l., S. Ilario d‘Enza, Italy and Soudronic AG, Bergdietikon, Switzerland t e c h n i c a l d ata Ocsam Impianti s.r.l. Via Edison, 15 I-42040 S. Ilario d'Enza (RE) Italy Phone +39 0522 909742 r.a. Fax +39 0522 909794 E-Mail ocsaminfo@citynet.re.it www.ocsam.com s .p.m. mm mm s trips mm TSN211 BSS 10–50 W 500–1180 0.12–0.40 (*) 1–6 (*) 160–600 (*) 56–1200 Back Squaring System L 600–1200 Ø 45–189 TSN211 FSS 10–50 W 500–1180 0.12–0.40 (*) 1–2 (*) 280–1180 (*) 90–1200 Front Squaring System L 600–1200 Ø...

Open the catalog to page 8All Cantec catalogs and technical brochures

-

Capmaking systems CAP-O-MAT

8 Pages

-

Multi-die systems END-O-MAT

8 Pages

-

UNIPRESS

2 Pages

-

Soudronic Company

32 Pages

-

Testing systems

2 Pages

-

ECONOMIC CURING SYSTEMS

6 Pages

-

Seam protection systems

8 Pages

-

SQUAREPACK ® line to produce

2 Pages

-

BODYSHAPER

2 Pages

-

INLINE TACTILE MARKING UNIT

2 Pages

-

Sheet Feeder

6 Pages

-

END-O-MAT

3 Pages

-

END-O-MAT press

2 Pages

-

liner

1 Pages

-

Cap making systems

8 Pages

-

CAN-O-MAT Aerosol

2 Pages

-

Powder Monitor SPM-2

2 Pages

-

Belt Conveyor Transfer TX2

1 Pages

-

Cepak Slitter Equipment

4 Pages

-

Cepak Slitters

6 Pages

-

HEAt SEALING SYSTEM

2 Pages

-

Cepak Hybrid Slitters

2 Pages

-

Automatic canbody welders

6 Pages

-

BODYPACK

2 Pages

-

END-O-MAT Multi-die systems

8 Pages